Resources

Stay updated with AQUALITEK’s latest news, insights, and innovations in water treatment technologies. Discover trends,insights, and solutions shaping global water purification.

Impact of Winter Seawater Temperature Drop on RO Desalination Water Production and Operating Pressure| Insights by AQUALITEK

Explore how winter seawater temperature drops affect RO desalination systems, including water production decline, pressure increase, energy consumption changes, and practical optimization strategies for stable plant operation.

How to Quickly Determine If a Seawater RO Membrane Has Suffered Severe Scaling or Fouling| Insights by AQUALITEK

LLearn the fastest and most effective methods to diagnose severe scaling or fouling in seawater RO membranes, including key symptoms, performance indicators, inspection techniques, and preventive strategies.

Best Corrosion-Resistant Materials for Pipes and Components in Seawater Desalination Systems| Insights by AQUALITEK

This comprehensive guide explains the most commonly used corrosion-resistant materials for pipes and components in seawater desalination systems, including their advantages, limitations, and selection criteria, helping engineers and project owners choose the optimal materials for long-term stable operation.

What Is the Most Common Way to Discharge Concentrated Brine from Large-Scale Seawater Desalination Plants?| Insights by AQUALITEK

Discover the most widely used brine discharge method in large-scale seawater desalination plants, including deep-sea outfall systems, environmental protection measures, and design principles.

7 Critical Industrial Media Filter Mistakes That Are Ruining Your System’s Efficiency (2026 Guide)

Key Differences Between Cleaning Agent Formulations for Seawater RO Membranes and Brackish Water RO Membranes| Insights by AQUALITEK

Explore the critical differences between seawater RO and brackish water RO membrane cleaning formulations, including fouling types, chemical strength, pH ranges, and cleaning strategies.

Why Can’t Seawater RO Permeate Be Used Directly as Drinking Water?| Insights by AQUALITEK

Seawater RO produces ultra-pure water, but it cannot be consumed directly. Learn why remineralization and pH adjustment are essential for safe and healthy drinking water.

Why Must a Seawater Desalination System Be Flushed with Low-Pressure Fresh Water Before Slowly Increasing Pressure at Startup?| Insights by AQUALITEK

Learn why low-pressure freshwater flushing followed by gradual pressurization is essential when starting a seawater desalination RO system, and how it protects membranes and equipment.

The Two Most Common Pollutants in Seawater That Pose the Greatest Threat to RO Membranes| Insights by AQUALITEK

Discover the two most dangerous types of seawater pollutants for RO membranes—particulate/colloidal matter and biological contaminants—and learn why they dominate fouling risks in seawater desalination.

Before Seawater Enters the RO Membrane, What SDI Level Must Pretreatment Achieve?| Insights by AQUALITEK

Learn what SDI level seawater pretreatment must reach before RO membranes, why SDI control is critical, and how modern desalination plants achieve stable low SDI.

How Does an Energy Recovery Device Save Energy in a Seawater Desalination Plant?| Insights by AQUALITEK

Understand how energy recovery devices (ERDs) work in seawater desalination plants, how they recycle high-pressure brine energy, and why they are essential for low-energy SWRO systems.

Why Is the Operating Pressure of a Seawater Desalination RO System Much Higher Than That of Tap Water RO Systems?| Insights by AQUALITEK

Learn why seawater RO systems require much higher operating pressure than tap water RO, focusing on osmotic pressure, salinity, membrane design, and energy considerations.

Besides the RO Membrane and High-Pressure Pump, What Is the Key Energy-Saving Device Unique to Seawater Desalination Systems?| Insights by AQUALITEK

Discover why energy recovery devices (ERDs) are essential in seawater desalination systems but absent in household RO, and how they dramatically reduce energy consumption.

What Is the Seawater RO–Brackish Water RO Two-Stage Series Process? How Does It Achieve Higher Recovery and Lower Energy Consumption?| Insights by AQU

Learn how the seawater RO–brackish water RO (SWRO–BWRO) two-stage series process improves overall recovery and reduces energy consumption in modern desalination systems.

How Much Energy Can Advanced Energy Recovery Devices Theoretically Recover from High-Pressure Brine in Seawater Desalination Systems?| Insights by AQU

Discover how much energy modern energy recovery devices can theoretically recover from high-pressure brine in seawater desalination and how this impacts overall desalination efficiency.

Environmental Impacts of High-Salinity Brine Discharge from Seawater Desalination Plants and How to Mitigate Them| Insights by AQUALITEK

High-salinity brine discharge is a major environmental concern in seawater desalination. Learn the key ecological risks and proven mitigation strategies used worldwide.

How Next-Generation High-Flux Seawater Desalination Membranes Achieve High Salt Rejection While Increasing Water Flux| Insights by AQUALITEK

Discover how new-generation high-flux seawater desalination membranes use advanced materials and structural design to increase water permeability without compromising salt rejection.

Industrial Water Purified: A Guide to the Best Reverse Osmosis Systems for Scalable Production

Maximize your ROI with our 2026 guide to the best reverse osmosis systems. Master industrial RO system cost, expert installation, and filtration secrets to ensure reliable, scalable production.

Why Must Seawater Inside RO Membranes Be Immediately Replaced with Low-Salinity Water After an Emergency Shutdown?| Insights by AQUALITEK

After a sudden shutdown of a seawater desalination RO system, immediate flushing with low-salinity water is critical. Learn why this step is essential to protect membranes and system integrity.

Why Does Desalinated Seawater Require Remineralization or pH Adjustment Before Drinking?| Insights by AQUALITEK

Desalinated seawater is extremely low in minerals and often acidic. Discover why remineralization and pH adjustment are essential before potable use.

Key Indicators Requiring Special Attention in Seawater Desalination Operation| Insights by AQUALITEK

In seawater desalination systems, standard parameters alone are not enough. Discover the critical additional indicators that operators must closely monitor to ensure safety, stability, and long-term performance.

The Most Common Scaling Types in Seawater Desalination Systems and How to Prevent Them| Insights by AQUALITEK

Scaling is one of the main operational risks in seawater desalination RO systems. Learn which scaling types are most common and the most effective prevention strategies.

How Does the Chemical Cleaning of Seawater Desalination Membranes Differ from That of Brackish Water Membranes?| Insights by AQUALITEK

Chemical cleaning of seawater RO membranes differs significantly from brackish water RO due to salinity, fouling types, and materials. Learn the key differences and best practices.

How Should Materials Be Selected for Seawater Desalination Systems to Address Seawater Corrosion?| Insights by AQUALITEK

Material selection is critical for seawater desalination systems due to severe corrosion risks. Learn best practices for choosing pipes, pumps, and pressure vessels.

What Are the Special Requirements for Flushing and Pressurization Before Starting a Seawater Desalination System?| Insights by AQUALITEK

Improper flushing and pressurization are major causes of early membrane damage in seawater RO systems. This article explains the special startup requirements and best practices to ensure safe desalination system operation.

How Can Cavitation Be Prevented in High-Pressure Pumps Operating in Highly Corrosive Media Such as Seawater?| Insights by AQUALITEK

Cavitation is one of the most destructive failures in seawater RO high-pressure pumps. This article explains why it occurs in corrosive media and outlines best prevention strategies.

Purity in Production: The Essential Role of Stainless Steel Water Filters in the Food & Beverage Industry

A stainless steel water filter is the cornerstone of purity and durability in food and beverage production. Choosing the right water filter for industry ensures consistent quality and strict safety compliance. Upgrade to a professional commercial water filter system to protect your brand and optimize your entire production line.

How to Effectively Prevent Microorganism and Algae Proliferation in Seawater Desalination Systems?| Insights by AQUALITEK

Microorganisms and algae are major threats to seawater desalination systems. Learn the most effective strategies to prevent biological proliferation and protect membranes from biofouling.

Why Is Boron Removal from Seawater So Challenging?| Insights by AQUALITEK

Boron removal is one of the most difficult challenges in seawater desalination. This article explains why boron is hard to remove and reviews the best available treatment methods used in modern RO systems.

Why Single-Pass Seawater desalination Recovery Is Typically Limited to 40–50%| Insights by AQUALITEK

Why are most RO desalination systems designed with a single-pass recovery of only 40–50%? This article explains the technical, chemical, and economic reasons behind this industry-standard design choice.

What Substances Must Be Critically Controlled During Seawater RO Pretreatment?| Insights by AQUALITEK

Seawater pretreatment is crucial for RO system reliability. This article explains which substances must be removed or controlled before seawater enters RO membranes and why each one matters.

Typical Operating Pressure of Seawater Desalination RO Systems: Range and Reasons| Insights by AQUALITEK

What is the normal operating pressure of a seawater RO system, and why is it much higher than brackish water RO? This article explains pressure ranges, driving forces, and engineering reasons in detail.

Why Energy Recovery Devices Are Crucial in RO Desalination: Mainstream Technologies Explained| Insights by AQUALITEK

Why are energy recovery devices essential in RO desalination systems? This article explains their role, benefits, and compares the mainstream ERD technologies used in modern seawater RO plants.

Seawater RO vs. Brackish Water RO: Key Design Differences You Must Understand| Insights by AQUALITEK

Seawater RO systems differ fundamentally from brackish water RO systems in pressure, membranes, pretreatment, materials, and energy consumption. Learn the key design differences and selection principles.

Core Pressure Components Required in a Seawater Desalination RO System| Insights by AQUALITEK

A seawater RO system operates under extreme pressure. This article explains the essential pressure-bearing components required in SWRO systems and why each one is critical for safety, efficiency, and reliability.

9 Essential Benchmarks for Deionized Water Quality (2026 Guide)

This comprehensive 2026 guide details the 9 essential quality benchmarks for industrial deionized water systems, covering resistivity, TOC, and silica limits. It provides expert insights on ASTM standards, system maintenance, and procurement strategies to maximize ROI and ensure compliance in high-purity applications.

Can You Replace Only the Poor-Performing RO Membrane

Replacing only a poor-performing RO membrane may seem cost-effective, but it carries hidden operational risks. Learn when it’s acceptable, the risks involved, and best practices to avoid system imbalance.

If RO Permeate Smells Like Rotten Eggs, What Contaminant Is Likely Present?| Insights by AQUALITEK

A rotten egg smell in RO permeate is a serious warning sign. Learn which contaminants cause this odor, how to confirm the source, and what corrective actions should be taken immediately.

Why Does RO Permeate Conductivity Temporarily Increase After Membrane Cleaning?| Insights by AQUALITEK

A short-term rise in RO permeate conductivity after chemical cleaning is common. Learn the real reasons behind it, whether it’s normal, and how to restore stable water quality quickly.

What Are the Immediate Effects of Reducing the Concentrate Valve Opening on the High-Pressure Pump and RO Membrane?| Insights by AQUALITEK

Reducing the concentrate valve opening in an RO system has immediate effects on pressure, pump load, and membrane performance. Learn how this adjustment impacts system safety, recovery, and membrane lifespan.

What Problems Can Be Identified Visually from a Disassembled RO Membrane Element?| Insights by AQUALITEK

A disassembled RO membrane element reveals valuable clues about fouling, scaling, oxidation, and mechanical damage. Learn how visual inspection helps diagnose system problems quickly and accurately.

Can the Inlet End and Concentrate End of an RO Pressure Vessel Be Interchanged During Installation?| Insights by AQUALITEK

Interchanging the inlet and concentrate ends of an RO pressure vessel can cause severe performance and safety issues. Learn why RO pressure vessels are direction-specific and how incorrect installation affects membranes and seals.

What Could Be Causing an RO System to Shut Down Due to a “Low Inlet Pressure” Alarm?| Insights by AQUALITEK

A low inlet pressure alarm is a common cause of RO system shutdowns. Learn the most common mechanical, hydraulic, and operational reasons behind low inlet pressure and how to troubleshoot them effectively.

Why Is Electricity Consumption Rising While RO Water Production Remains Unchanged?| Insights by AQUALITEK

If an RO system’s water production stays constant but electricity costs rise sharply, energy efficiency has deteriorated. Learn where to focus your investigation and how to identify hidden power losses.

Best Simple Anti-Freezing Measure for Outdoor Reverse Osmosis Pipes and Equipment| Insights by AQUALITEK

Outdoor RO pipes and equipment are highly vulnerable to freezing damage. Learn the simplest, most reliable anti-freezing measure for reverse osmosis systems installed outdoors and why it works.

What to Pay Attention to with the Sealing Ring When Installing a Security Filter Cartridge| Insights by AQUALITEK

Improper sealing ring installation in security filter cartridges can cause bypass, membrane fouling, and system failure. Learn the key details to check for reliable RO pretreatment performance.

Where Does a Continuous Hissing Sound During RO System Operation Come From?| Insights by AQUALITEK

A continuous hissing sound in an RO system often indicates pressure loss, leakage, or flow instability. Learn the common sources, risks, and troubleshooting steps to prevent system damage.

How to Temporarily Assess Water Quality When an Online Conductivity Meter Fails| Insights by AQUALITEK

When an online conductivity meter suddenly malfunctions, operators must still ensure RO permeate quality. This Best-practice guide explains reliable temporary methods to assess water quality safely.

Does the RO Permeate Pipeline Need Regular Cleaning? And Why It Matters| Insights by AQUALITEK

RO permeate pipelines are often overlooked in system maintenance. This Best-practice guide explains whether regular cleaning is necessary, why it matters, and what risks arise if it is ignored.

When RO Operating Data Looks “Too Good and Too Stable”: What Problems Might Be Hidden?| Insights by AQUALITEK

RO system data that appears unusually stable and perfect may indicate hidden risks. This Best-practice article explains why “too good-looking” RO operating data can signal sensor failure, bypass issues, control problems, or undetected membrane damage.

Essential Steps When Switching to the Standby High-Pressure Pump| Insights by AQUALITEK

Switching to a standby high-pressure pump in an RO system requires strict procedures. This Best-practice guide explains essential steps to ensure safety, membrane protection, and stable system performance.

Besides Valve Adjustment, What Other Factors Affect the Actual Recovery Rate of an RO System?| Insights by AQUALITEK

RO system recovery rate is not determined by valve adjustment alone. This Best-practice article explains all key factors that influence actual recovery, including feed water quality, temperature, membrane condition, pressure balance, fouling, and system design.

Used RO Membrane Utilization: Practical and Responsible Uses for Replaced Old Membrane Elements| Insights by AQUALITEK

Replaced RO membranes are not always waste. This Best-practice article explores feasible reuse scenarios, limitations, environmental considerations, and compliant disposal options for used RO membrane elements.

Can RO Membrane Surfaces Be Manually Cleaned Using Physical Methods Like Brushing?| Insights by AQUALITEK

Manually cleaning RO membranes with brushes or physical tools is a common misconception. This Best-practice guide explains why physical cleaning damages membranes, what irreversible risks it causes, and the correct alternatives for membrane cleaning.

Why Can RO Permeate Still Contain Excessive Bacteria Even Though RO Membranes Trap Bacteria?| Insights by AQUALITEK

RO membranes can physically reject bacteria, yet permeate bacterial counts may still exceed limits. This Best-practice article explains the real causes, risks, and proven control measures in industrial and commercial RO systems.

How to Confirm That Chemical Cleaning Agents Have Been Completely Rinsed Off in an RO System| Insights by AQUALITEK

Incomplete rinsing after RO chemical cleaning can contaminate permeate water and damage membranes. This Best-practice guide explains reliable methods to confirm that cleaning chemicals have been fully flushed from the system before returning to service.

The Ultimate Guide to Commercial Reverse Osmosis Systems for 2026

This definitive guide explores Commercial Reverse Osmosis (RO) systems for 2026. It covers the scientific principles of RO, detailed system components, specific industrial applications, and critical selection criteria. Readers will gain insights into maintenance best practices, troubleshooting common issues, and future technological trends, empowering businesses to make data-driven decisions for optimal water quality and ROI.

Slight Water Seepage at Both Ends of the RO Membrane Housing: Is It Serious and How Should It Be Handled?Insights by AQUALITEK

Slight water seepage at both ends of an RO membrane housing is a common issue, but it should never be ignored. This article explains the causes, risks, inspection steps, and correct handling methods to prevent membrane damage and system failure.

How to Quickly Distinguish Whether an RO Membrane Is Fouled by Scaling or Sludge| Insights by AQUALITEK

Learn how to quickly identify whether RO membrane fouling is caused by inorganic scaling or organic/sludge contamination. This practical guide covers key symptoms, data trends, and on-site diagnostic methods to help operators respond correctly and avoid irreversible membrane damage.

Using RO Permeate as Cooling Water: Key Precautions You Must Take| Insights by AQUALITEK

Using RO permeate directly as cooling water can improve heat transfer efficiency, but it also introduces corrosion, stability, and biological risks. This guide explains the key precautions, control strategies, and best practices to safely and economically use RO permeate in cooling systems.

Why Does the High-Pressure Pump Outlet Pressure Gauge Pointer Vibrate Violently?

Violent vibration of the pressure gauge pointer at the outlet of a high-pressure pump is a serious operating warning in RO systems. This Best-practice guide explains the most common causes, how to distinguish hydraulic from mechanical problems, and what actions should be taken to prevent equipment damage.

Why Extended Flushing Without Tank Filling Is Required During Initial RO System Startup| Insights by AQUALITEK

During the initial startup of a new RO system, operators are often instructed to flush the system for an extended period without sending permeate to the product water tank. This practice is not optional—it is essential for system safety, membrane protection, and long-term water quality stability. This article explains the technical reasons behind this critical startup procedure.

Where Are Scale Inhibitor and Reducing Agent Dosing Points Located in RO Systems?| Insights by AQUALITEK

Correct chemical dosing location is critical to the safe and efficient operation of an RO system. Scale inhibitors and reducing agents are two essential chemicals commonly used to protect RO membranes, but they must be injected at the correct points in the process. This article explains where these dosing points are typically located and why their placement matters.

How Long Should an RO System Be Flushed After Replacing Pretreatment Filter Media?| Insights by AQUALITEK

After replacing pretreatment filter media such as activated carbon or multimedia filters, improper flushing can allow fines, air, or residual chemicals to enter the RO system and cause irreversible membrane damage. This Best-practice guide explains how long flushing should take, what standards must be met, and when it is safe to start the RO system.

What Efficiency Does Operating Current Directly Measure?| Insights by AQUALITEK

Operating current is one of the most commonly monitored parameters in industrial equipment and RO systems. But what efficiency does it actually represent? This Best-practice guide clearly explains what operating current directly reflects, what it does not measure, and how operators should correctly interpret current data in daily operation.

Best Standards for Flushing Water After Chemical Cleaning Before Connecting to the Product Water Tank| Insights by AQUALITEK

After chemical cleaning (CIP) of an RO system, improper flushing can allow residual chemicals to contaminate the product water tank, causing quality failures and safety risks. This Best-practice guide explains the mandatory standards flushing water must meet before it is allowed to enter the product water tank.

Best Ways to Quickly Identify Whether an RO Membrane Element Is New or Used| Insights by AQUALITEK

In industrial RO systems, distinguishing between new and used membrane elements is critical for installation, troubleshooting, and warranty management. This Best-practice guide explains fast, reliable, and field-proven methods to identify whether an RO membrane element is new or old—without complex testing.

Which Direction Should RO Membrane Markings Face During Installation?| Insights by AQUALITEK

Incorrect orientation of an RO membrane element during installation can lead to internal leakage, reduced salt rejection, and even mechanical damage. This Best-practice guide clearly explains which side of the membrane markings should face, why it matters, and how to avoid common installation mistakes.

What Must Be Confirmed Before Adding Chemicals to an RO System| Insights by AQUALITEK

Adding scale inhibitors or bactericides without proper verification can cause irreversible RO membrane damage and system failure. This Best-practice guide explains the critical checks that must be completed before dosing any chemicals into an RO system.

Best Reverse Osmosis Water Filter Systems for industry in 2026

A comprehensive 2026 guide to finding the best reverse osmosis water filter system. This article explores how RO technology works, its efficiency and contaminant removal capabilities (including fluoride and microplastics), installation costs, and expert recommendations for homeowners and businesses.

Best Immediate Actions to Take When a Sudden Increase in Influent Hardness Is Detected| Insights by AQUALITEK

A sudden spike in influent water hardness is a serious operational risk for RO systems and can cause rapid, irreversible membrane scaling. This Best-practice guide explains the immediate steps operators must take to protect RO membranes, stabilize system operation, and prevent costly downtime.

Best Practical Ways to Verify the Accuracy of Product and Concentrate Flow Meters in RO Systems| Insights by AQUALITEK

Inaccurate flow meter readings can lead to incorrect recovery calculations, membrane damage, and inefficient RO operation. This Best-practice guide explains simple, fast, and reliable methods to verify whether product water and concentrate flow meters are reading accurately—without specialized calibration equipment.

Best Ways to Quickly Determine Whether an Odor in RO Permeate Originates Before or After the Membrane| Insights by AQUALITEK

Learn how to rapidly identify whether an odor in RO permeate is caused by issues in the feed water (before the membrane) or contamination occurring after the membrane. This guide provides practical diagnostic methods, expert tips, and actionable procedures for RO operators and water treatment professionals.

Best Simple Protective Measure for RO Systems Scheduled to Shut Down for 3–7 Days| Insights by AQUALITEK

When an industrial RO system is expected to stop running for 3–7 days, improper handling can lead to biological growth, foul odors, and even irreversible membrane damage. This Best-class guide explains the simplest, safest, and most reliable protection method, along with steps, reasons, and essential precautions.

What Tasks Still Require Manual Intervention in a Fully Automated RO System?| Insights by AQUALITEK

Even the most advanced fully automated RO (Reverse Osmosis) systems cannot operate 100% unattended. This article explains which operational, maintenance, and monitoring tasks still require manual intervention—and why these actions are essential for long-term system stability, membrane protection, and water quality control.

Best Safety Precautions for Disassembling RO Membrane Housing End Plates| Insights by AQUALITEK

Learn the essential safety precautions required when disassembling RO membrane housing end plates. This guide covers risks, step-by-step protective measures, and best practices to ensure safe, efficient RO system maintenance.

What Is the Main Purpose of Low-Pressure Flushing Before and After RO System Startup and Shutdown?| Insights by AQUALITEK

Low-pressure flushing is a standard and essential operating procedure in RO (Reverse Osmosis) systems. This article explains why flushing is required before startup and after shutdown, how it protects RO membranes, and the overall benefits to system stability and longevity.

Why Is the pH Value of RO Treated Water Usually Lower Than That of the Influent?| Insights by AQUALITEK

RO (Reverse Osmosis) produced water often shows a slightly lower pH compared to the feed water. This article explains the scientific reasons behind this phenomenon, the impact on system performance, and what operators should know when monitoring RO permeate pH.

Ultimate Guide to Water Treatment Systems for Well Water 2026

Comprehensive guide to water treatment systems for well water in 2026, covering industrial solutions and safety.

Emergency Measures for Damaged RO Membrane Elements or Leaking Seals | Insights by AQUALITEK

This Best-style guide explains the emergency actions required when an RO membrane element is damaged or when a seal is leaking. It covers how to identify symptoms, immediate safety steps, temporary operating strategies, risks of continued use, and proper replacement procedures.

Best Water Temperature Range for RO Systems: Complete Guide for Optimal Performance| Insights by AQUALITEK

Understanding the ideal water temperature range for RO (Reverse Osmosis) systems is essential for ensuring stable performance, high permeate flow, and long membrane life. This guide explains the recommended temperature range, how temperature affects system efficiency, and best practices for both home and industrial RO applications.

How to Initially Assess Scale Risk from an Influent Water Quality Report| Insights by AQUALITEK

This Best-style guide explains how engineers and water treatment professionals can evaluate scale formation risks in RO, NF, and industrial water systems by interpreting influent water quality data. It covers key water parameters, diagnostic methods, and practical evaluation techniques to support reliable system design and operation.

Main Categories of RO System Malfunctions | Insights by AQUALITEK

This Best-style guide explains the major categories of malfunctions in industrial RO (reverse osmosis) systems. It covers mechanical, hydraulic, electrical, chemical, membrane-related, and operational issues, helping engineers diagnose problems quickly and optimize system performance.

What Are the Criteria for Replacing the Filter Cartridge of a Pre-Filter? (Expert RO System Guide)| Insights by AQUALITEK

Learn the clear and practical criteria for replacing pre-filter cartridges such as PP cotton, activated carbon, and composite filters. This expert guide explains visual signs, pressure changes, taste issues, RO protection needs, and time-based replacement rules.

Why High-Pressure Pumps Should Avoid Frequent Starts and Stops (Expert RO System Guide)| Insights by AQUALITEK

Learn why high-pressure pumps in RO systems must not start and stop frequently within short intervals. This expert guide explains mechanical, electrical, hydraulic, and membrane-related risks, with best practices for stable and safe operation.

What Irreversible Damage Can Residual Chlorine and Oxidants Cause to RO Membranes? (Expert Industrial Guide)| Insights by AQUALITEK

Residual chlorine and oxidants can cause irreversible degradation of RO membranes. This in-depth guide explains the chemical damage mechanisms, performance impacts, early warning signs, and best preventive measures for industrial RO systems.

What Operational Data Must Be Recorded Long-Term in RO Systems? (Professional Guide)| Insights by AQUALITEK

Learn the essential operational data that must be recorded long-term in RO (Reverse Osmosis) water treatment systems. This guide covers key indicators, why long-term logs matter, best practices, and expert tips for stable performance and predictive maintenance.

Which Small Component Must Be Checked When Replacing a Membrane Element? (Professional RO Guide)| Insights by AQUALITEK

Learn the most important small component that must be inspected when replacing RO membrane elements. This expert guide explains why the interconnector and seals matter, how failures occur, and best practices to ensure leak-free system performance.

Best Guide: Can the Recovery Rate of an RO System Be Arbitrarily Increased?| Insights by AQUALITEK

Many operators hope to increase the recovery rate of an RO system to reduce wastewater and improve efficiency. However, raising recovery is not unlimited—beyond certain thresholds it harms membrane performance, increases fouling risk, and shortens system lifespan. This guide explains the principles, limitations, risks, and best practices for setting an appropriate RO recovery rate.

Best Guide: What Are the Possible Causes of an Off-Odor in RO Produced Water?| Insights by AQUALITEK

RO-purified water should be clean, odorless, and fresh. When the permeate develops an unusual smell, it usually indicates problems in pretreatment, membrane performance, post-filtration components, or system hygiene. This article explains the common causes of off-odor in RO water, how to diagnose them, and how to resolve the issue effectively.

When Should RO Membrane Elements Be Sent for Offline Cleaning?| Insights by AQUALITEK

Learn when RO membranes require offline cleaning, the signs of severe fouling, situations where on-site CIP is no longer effective, and how professional offline restoration improves performance and extends membrane life.

Best Guide: How Should Spare New RO Membranes Be Stored and Handled?| Insights by AQUALITEK

Proper storage and handling of spare RO membranes are critical to maintaining performance, ensuring long-term reliability, and preventing irreversible damage. This guide explains recommended storage conditions, precautions, common mistakes, and best practices for inventory management.

Best Guide: How to Determine if an RO System Is Contaminated with Biological Substances—and How to Handle It| Insights by AQUALITEK

Biological contamination is one of the most common and damaging issues in industrial RO systems. It leads to rapid performance decline, biofouling, membrane clogging, higher differential pressure, and product water quality deterioration. This article explains how to identify biological contamination early and provides effective strategies to clean, control, and prevent it.

Is More Frequent Chemical Cleaning Always Better for RO Systems?| Insights by AQUALITEK

Is frequent chemical cleaning beneficial for RO systems? Learn the optimal cleaning frequency, risks of over-cleaning, key indicators for CIP timing, and best practices to protect membrane lifespan and system performance.

Best Guide: What Water Accumulation at One End of an RO Membrane Element Really Means| Insights by AQUALITEK

When an RO membrane element is removed from the pressure vessel and one end is found filled with water, it is often a sign of abnormal flow distribution, seal failure, or internal damage. This article explains the possible causes, how to diagnose them, and what operators should do next.

Best Guide: What Direct Harm Does Pretreatment Failure Cause to an RO Membrane?| Insights by AQUALITEK

Pretreatment is the frontline protection of every industrial RO system. When pretreatment equipment—such as multimedia filters, carbon filters, cartridge filters, or softeners—fails or operates improperly, the RO membrane becomes immediately exposed to suspended solids, hardness ions, chlorine, and organics. This article explains the direct damage caused by pretreatment failure and why it can drastically shorten membrane lifespan.

Best Guide: What Are the Main Sources of Cost for Operating an Industrial RO System?| Insights by AQUALITEK

Operating an industrial RO (Reverse Osmosis) system involves much more than just the initial equipment purchase. From energy use to membrane replacement, labor, and chemical consumption, understanding the main operating cost drivers can help businesses optimize budgets, maximize efficiency, and extend system lifespan. In this guide, we break down the most important cost components in running an industrial RO system.

Best Guide: What Is the Correct Startup Sequence for an Industrial RO System?| Insights by AQUALITEK

Starting up an industrial RO (Reverse Osmosis) system is a critical step that directly affects membrane life, system stability, and operating costs. Many RO failures happen because operators skip important steps and start the high-pressure pump too early. In this guide, you will learn the correct startup sequence and the risks of improper operation.

Best Guide: How Inlet Water Temperature Affects an RO System| Insights by AQUALITEK

Inlet water temperature plays a critical yet often underestimated role in the performance, efficiency, and lifespan of a reverse osmosis (RO) system. From permeate flow and salt rejection to energy consumption and membrane protection, temperature has a direct impact on nearly every aspect of RO operation. This article explains the key effects and how to optimize your system for stable operation.

Best First Steps to Check After a Sudden Power Outage or RO System Shutdown| Insights by AQUALITEK

A sudden power outage or unexpected shutdown of a reverse osmosis (RO) system can quickly lead to pressure imbalances, equipment stress, membrane fouling, and even permanent damage if not handled correctly. Knowing the proper first steps to take is critical for protecting your system and restoring safe, stable operation. This guide outlines the essential checks and best practices to follow.

Best Basic Skills Required for Personnel Operating Industrial RO Systems| Insights by AQUALITEK

Operating an industrial reverse osmosis (RO) system is not simply about pressing start and stop buttons. It requires a mix of technical knowledge, hands-on operational skills, and strong awareness of safety and water quality requirements. In this guide, we break down the most important skills every industrial RO operator should master.

Best Precautions for Operating an RO System in a Cold Environment (Expert Guide)| Insights by AQUALITEK

Operating a reverse osmosis (RO) system in cold environments presents unique challenges such as freezing risks, reduced performance, and potential equipment damage. This best-practice guide explains how to protect your RO system, maintain stable performance, and avoid costly failures when temperatures drop.

Best Online Instruments Crucial to the Operation of an RO System| Insights by AQUALITEK

Online instruments play a critical role in ensuring stable performance, water quality, and operational safety in reverse osmosis (RO) systems. This best-practice guide highlights the key monitoring devices every RO system should be equipped with to maintain efficiency, prevent damage, and meet water quality standards.

Best Situations That Require RO Membrane Replacement — Even Without Obvious Performance Loss| Insights by AQUALITEK

Most people think RO membranes only need replacement when water quality or flow rate declines. In reality, several hidden risks and abnormal conditions may require immediate membrane replacement even when performance appears normal. This article explains the best non-performance-related reasons to replace an RO membrane and how to identify them early.

Best Actions to Take When RO Chemical Cleaning Is Ineffective| Insights by AQUALITEK

RO membrane chemical cleaning (CIP) is designed to restore performance when fouling or scaling occurs. But what happens when cleaning no longer works? This article explains the best next steps to take when RO chemical cleaning fails, how to confirm irreversible damage, and how to prevent repeated failure in the future.

Top 10 Water Filters for Industrial Applications 2026

Explore the top 10 industrial water filters, including reverse osmosis, for efficient water treatment in businesses.

Best Parameters to Test in RO Permeate Water (Besides Conductivity)| Insights by AQUALITEK

While conductivity is a key indicator of RO permeate quality, relying on it alone is not enough. To ensure system performance, membrane integrity, and water safety, additional parameters must be tested routinely. This guide covers the most important water quality indicators beyond conductivity and explains why they matter.

Best Ways to Identify RO Membrane Fouling or Scaling at an Early Stage| Insights by AQUALITEK

RO membrane fouling and scaling are two of the most common causes of performance loss in reverse osmosis systems. Catching the problem early can prevent permanent damage and expensive replacements. This article explains the best indicators and evaluation methods to determine if your RO membrane has started to foul or scale.

Best Practices: What to Do When RO Feed Water Quality Suddenly Deteriorates| Insights by AQUALITEK

A sudden deterioration in feed water quality can severely impact RO system performance, cause membrane fouling, and even lead to system shutdown. This article explains the risks, warning signs, and best response actions to protect your RO system and maintain stable operation.

Best Practices: What Causes Abnormal Noise in a High-Pressure Pump?| Insights by AQUALITEK

Abnormal noise from a high-pressure pump is a critical warning sign in an RO system. It may indicate mechanical issues, cavitation, air intrusion, poor lubrication, or system design problems. This article explains the most common causes, risks, and troubleshooting actions.

Best Practices: Simple Protective Measures for Safely Shutting Down an Industrial RO System| Insights by AQUALITEK

When an industrial RO system needs to be shut down for days, weeks, or even months, proper protective measures are essential to prevent membrane fouling, microbial growth, and long-term performance loss. This article explains the simplest and most effective shutdown protection methods based on different downtime durations.

Essential Precautions Before Powering On a Newly Installed or Long-Term Unused RO System| Insights by AQUALITEK

Whether you are commissioning a newly installed reverse osmosis (RO) system or restarting one that has been idle for weeks or months, proper precautions are essential. RO membranes are highly sensitive, and improper startup can lead to irreversible fouling, oxidation, or mechanical damage.

Best Guide: What Are the Main Differences Between Industrial and Home-Use RO Systems?| Insights by AQUALITEK

Best Guide: What Are the Most Crucial and Expensive Consumables in an Industrial RO System?| Insights by AQUALITEK

Industrial RO systems rely on several key consumables that directly affect water quality, system performance, and long-term operating cost. This Best Guide explains the most important—and often the most expensive—consumables, how they work, and how to manage them efficiently.

Best Guide: What Is the Typical Lifespan of an Industrial RO Membrane?| Insights by AQUALITEK

How long do industrial RO membranes last? This Best Guide explains the typical lifespan of RO membranes, the factors that affect longevity, real-world expectations, and how factories can extend membrane life and reduce replacement costs.

Best Guide: What Should I Do If the Membrane Performance Cannot Be Restored After Cleaning?| Insights by AQUALITEK

When RO membrane cleaning fails to restore performance, it often indicates irreversible fouling, aging, or operational issues. This Best Guide explains why membrane performance may not recover after CIP, how to diagnose the root cause, and what actions factories should take next.

Best Guide: What Regular Maintenance Does an RO System Require Besides Membrane Replacement?| Insights by AQUALITEK

Membrane replacement is important, but it is NOT the only maintenance task needed to keep an RO (Reverse Osmosis) system running efficiently. This Best Guide explains all essential maintenance activities—from pretreatment upkeep to pump servicing and system cleaning—ensuring stable water quality, lower operating cost, and long-term reliability.

Best Guide: Where Does the Majority of an RO System’s Power Consumption Come From?| Insights by AQUALITEK

Power consumption is one of the largest operational costs in any RO (Reverse Osmosis) water treatment system. This Best Guide explains where most of the energy is used, why RO requires high pressure, and how factories can reduce electricity consumption while maintaining stable production.

Best Guide: What Are the Most Important Factors to Consider When Selecting RO Equipment for a Factory?| Insights by AQUALITEK

Selecting RO (Reverse Osmosis) equipment for a factory is not just a purchase—it’s a strategic investment that influences water quality, production stability, and long-term operational costs. This Best Guide explains the core factors factories must evaluate before choosing an RO system, ensuring maximum efficiency, compliance, and cost-effectiveness.

Best Guide: Key Parameters That Must Be Recorded and Checked During Daily RO System Operation| Insights by AQUALITEK

Daily monitoring of RO (Reverse Osmosis) equipment is essential for ensuring stable operation, preventing membrane fouling, and extending the lifespan of the system. This Best Guide explains all critical operational parameters that should be recorded, what they mean, why they matter, and how they help keep the RO system in optimal condition.

Best Guide: How Influent Pressure and Inter-Stage Pressure Affect RO Operation| Insights by AQUALITEK

Understand the impact of influent pressure and inter-stage pressure on reverse osmosis (RO) system performance. Learn how these factors affect permeate flow, membrane lifespan, and energy consumption, and how to optimize them for efficient operation.

Best Guide: How is the Concentrate Produced by Industrial RO Systems Typically Treated?| Insights by AQUALITEK

Learn about the methods used to treat the concentrate (brine or reject water) produced by industrial reverse osmosis (RO) systems. Understand the challenges and solutions for managing concentrate waste, including disposal options, treatment technologies, and environmental considerations.

Best Guide: Why Scale Inhibitors Are Essential in RO Systems| Insights by AQUALITEK

Learn why scale inhibitors are crucial in reverse osmosis (RO) systems, how they prevent scaling, extend membrane lifespan, and improve system efficiency. Understand their working principles, types, and correct dosing methods for industrial water treatment applications.

Best Guide: How to Control Bacterial Growth in an RO System| Insights by AQUALITEK

Learn how to effectively control bacterial growth in reverse osmosis (RO) systems through optimized pretreatment, disinfection methods, system design, and regular maintenance. Prevent biofouling, improve water quality, and extend membrane lifespan with proven industrial strategies.

Best Guide: The Most Common Operational Problems in Industrial RO Systems and How to Solve Them| Insights by AQUALITEK

Learn about the most common operational problems in industrial reverse osmosis (RO) systems—including fouling, scaling, biofouling, and pressure fluctuations. Discover expert insights into causes, prevention, and maintenance strategies to ensure stable water quality and long-term system efficiency.

Best Guide: Main Types of RO Membrane Clogging and Their Solutions| Insights by AQUALITEK

RO (Reverse Osmosis) membrane clogging is one of the most critical issues affecting water treatment system performance. Over time, contaminants in feedwater can accumulate on the membrane surface, reducing flux, increasing operating pressure, and compromising product water quality. This article explores the main types of RO membrane clogging, their causes, identifying symptoms, and effective solutions to maintain long-term system performance.

Best Technical Overview: Main Components of an Industrial RO System| Insights by AQUALITEK

An industrial reverse osmosis (RO) system is composed of multiple interdependent components that work together to purify water efficiently and reliably. This article provides a comprehensive breakdown of the main components in an RO system, explaining their functions, design considerations, and how they contribute to system performance and longevity.

Best Guide: Why Industrial RO Systems Require Strict Pretreatment Processes| Insights by AQUALITEK

Pretreatment is the foundation of any industrial reverse osmosis (RO) system. Without a robust pretreatment process, even the most advanced membranes and control systems cannot perform efficiently. This article explains why strict pretreatment is critical, what contaminants it targets, and how it impacts membrane performance, operational stability, and total lifecycle cost.

Best Evaluation Guide: Replacing RO Membranes or Upgrading the Entire System After 15–20 Years| Insights by AQUALITEK

When a large-scale reverse osmosis (RO) system approaches the end of its design life, operators must decide whether to replace the membranes or upgrade the entire system. This article explains the key technical and economic indicators used to make that decision, helping optimize long-term performance, safety, and cost-efficiency.

Best Industry Overview: Where Industrial RO Systems Are Used| Insights by AQUALITEK

Industrial reverse osmosis (RO) systems play a critical role in providing purified water across a wide range of sectors—from power generation and pharmaceuticals to food processing and electronics manufacturing. This article explores the major industries that rely on RO technology, their unique water quality demands, and how RO helps ensure reliability, safety, and cost efficiency.

Enabling Online Maintenance in Critical Seawater RO Systems| Insights by AQUALITEK

In large-scale or mission-critical seawater desalination plants, system downtime means water supply disruption and major financial losses. This article explains how to design Reverse Osmosis (RO) systems for online maintenance—allowing operators to isolate and service individual membrane pressure vessels without shutting down the entire water production process.

Best Analysis: When Premium RO Membranes Are the Most Economical Choice| Insights by AQUALITEK

Selecting the right reverse osmosis (RO) membrane isn’t just about upfront cost—it’s about total lifecycle performance. This article analyzes when investing in high-end membrane brands, despite their higher price, delivers better long-term value through reduced energy consumption, lower maintenance, and longer operational lifespan.

Ultimate Guide to Industrial Reverse Osmosis Systems in 2026

Explore AQUALITEK's 2026 guide to industrial reverse osmosis systems. Reliable, cost-effective solutions to optimize your water treatment today.

How Energy Recovery Devices Improve RO Efficiency — From Turbines to Pressure Exchangers| Insights by AQUALITEK

Energy Recovery Devices (ERDs) are the core of seawater desalination efficiency. From early turbine-based systems to today’s high-efficiency isobaric pressure exchangers, ERD technology has dramatically reduced RO energy consumption. This article explains their working principles, evolution, and current efficiency levels in modern desalination systems.

How to Build Compact, Corrosion-Resistant RO Desalination Systems for Ships and Islands Description| Insights by AQUALITEK

Marine and island desalination systems face harsh environments with high salinity, limited space, and constant vibration. This article explains how to design seawater RO systems optimized for corrosion resistance, impact resistance, and compactness — ensuring stable and efficient operation in demanding offshore conditions.

How to Prevent Scaling in Brackish Water RO Systems| Insights by AQUALITEK

Brackish water with high hardness and salinity presents a major challenge for reverse osmosis (RO) systems. Without proper design and pretreatment, calcium carbonate (CaCO₃) and calcium sulfate (CaSO₄) scaling can severely reduce membrane performance. This article explains the causes of scaling and the best engineering and chemical strategies to prevent it.

Integrating Ultrafiltration and Microfiltration as Pretreatment for RO Systems| Insights by AQUALITEK

In modern integrated membrane systems, ultrafiltration (UF) and microfiltration (MF) are increasingly used as key pretreatment stages before reverse osmosis (RO). This article explores how UF/MF units enhance RO performance, their design integration methods, and how backwash water can be effectively recovered and reused to reduce waste and operational costs.

Challenges and Pretreatment Optimization for RO in Wastewater and Greywater Reuse Projects| Insights by AQUALITEK

Reverse osmosis (RO) plays a critical role in advanced wastewater and greywater reuse, producing high-quality reclaimed water. However, wastewater presents unique challenges such as fouling, scaling, and organic loading. This article explores the main operational challenges and effective pretreatment strategies to ensure stable RO performance.

Why EDI Is Installed After RO in Ultrapure Water Systems| Insights by AQUALITEK

In ultrapure water production for electronics and pharmaceutical manufacturing, the combination of RO (Reverse Osmosis) and EDI (Electrodeionization) is the industry standard. This article explains why EDI units are typically installed after RO systems, how they complement each other, and what advantages this configuration offers for high-purity applications.

RO System Shutdown — Standard Storage and Maintenance Procedures to Prevent Membrane Damage| Insights by AQUALITEK

Proper storage and maintenance during short-term or long-term RO system shutdowns are essential to prevent microbial growth, scaling, and irreversible membrane damage. This article explains the standard procedures, preservation chemicals, and best practices for safe membrane protection.

Common Causes of Abnormally High Influent and Inter-Stage Pressures in RO Systems| Insights by AQUALITEK

Abnormally high influent and inter-stage pressures are early warning indicators of operational issues in reverse osmosis (RO) systems. Understanding their causes helps operators quickly diagnose problems, prevent membrane damage, and optimize system performance.

Top 5 Industrial Reverse Osmosis Systems in 2026

Discover 2026's top 5 industrial reverse osmosis systems. Reliable, cost-effective water treatment solutions for all industrial needs.

Main Types of Membrane Fouling in RO Systems — Scaling, Colloidal, Biofouling, and Organic Fouling| Insights by AQUALITEK

Membrane fouling is one of the most critical challenges in reverse osmosis (RO) operations. Understanding the types, causes, and characteristics of fouling helps optimize pretreatment design, cleaning strategies, and membrane lifespan.

Chemical Cleaning of RO Membranes — Cleaning Agents and Procedures for Different Fouling Types| Insights by AQUALITEK

Chemical cleaning is an essential maintenance process for reverse osmosis (RO) membranes, restoring flux, maintaining salt rejection, and extending membrane life. This article explains how RO chemical cleaning works, the cleaning agents used, and procedures tailored to different fouling types.

Understanding SDI (Silt Density Index) and Its Critical Role in Reverse Osmosis Systems| Insights by AQUALITEK

Learn what SDI (Silt Density Index) means in reverse osmosis (RO) systems, why it’s one of the most important parameters for pretreatment design, how it is measured, and what levels are acceptable for different RO applications.

Understanding Standardized Flux and Standardized Salt Transmittance in Industrial RO Systems| Insights by AQUALITEK

Standardized flux and standardized salt transmittance are key indicators for monitoring RO membrane health. They eliminate the effects of temperature and pressure changes, helping operators accurately evaluate membrane performance degradation over time.

What Is an Energy Recovery Device (ERD) and Why Is It Essential in Seawater Desalination RO Systems?| Insights by AQUALITEK

Energy Recovery Devices (ERDs) play a critical role in seawater reverse osmosis (SWRO) systems by capturing and reusing high-pressure energy from concentrated brine. This dramatically reduces power consumption, improves membrane performance, and lowers the cost of desalination. This article explains working principles, types of ERDs, and includes technical diagrams for system engineering reference.

Is an Online Cleaning System Necessary in Industrial RO Systems? Design Considerations and Cleaning Chemical Selection| Insights by AQUALITEK

Online Cleaning System (CIP) is crucial in industrial RO plants to maintain membrane performance and extend service life. This article explains why CIP is necessary, how to design an efficient cleaning system, and how to choose suitable cleaning chemicals for different fouling types.

What Is the Brine Water Recirculation Process in RO Systems? Benefits & Potential Risks| Insights by AQUALITEK

Learn how brine (concentrate) water recirculation enhances RO system recovery, and understand the associated risks such as scaling, fouling, and operational instability — with best engineering practices.

How to Select High-Pressure Pumps for Industrial Reverse Osmosis (RO) Systems| Insights by AQUALITEK

This guide explains the key types of high-pressure pumps used in industrial RO systems—centrifugal pumps and plunger (positive displacement) pumps. It covers performance characteristics, selection criteria, and best application scenarios to help engineers achieve high efficiency, stability, and cost-effectiveness in RO water treatment design.

How Industrial RO Systems Integrate EDI or Mixed-Bed Ion Exchange for Ultrapure Water Production| Insights by AQUALITEK

Discover how industrial RO systems use EDI (electrodeionization) or mixed-bed ion exchange as polishing steps to produce ultrapure water, and understand the key design considerations for reliable water quality performance.

How to Select RO Membrane Housing Materials — FRP vs. Stainless Steel| Insights by AQUALITEK

Learn how to choose the right reverse osmosis (RO) membrane housing material — FRP or stainless steel — with a complete comparison of working conditions, corrosion resistance, cost, and application suitability.

How to Select the Right RO Membrane Element for Large-Scale Systems| Insights by AQUALITEK

Learn how to select the right reverse osmosis (RO) membrane element — brackish water, seawater desalination, or anti-fouling membrane — and discover the key considerations for large-scale industrial RO design.

Multi-Stage RO System Design — Flow & Pressure Configuration and Interstage Booster Pump Usage| Insights by AQUALITEK

Learn how flow rates and pressures are configured between stages in multi-stage RO systems, why pressure drops occur, and when an interstage booster pump is required for stable and efficient operation.

How to Select Key Pretreatment Steps for Industrial RO Systems Based on Source Water Quality| Insights by AQUALITEK

Learn how to design the right pretreatment process for industrial reverse osmosis (RO) systems based on source water characteristics, including surface water, groundwater, seawater, and wastewater. Improve RO performance and protect membranes with targeted pretreatment strategies.

What Are “Flux” and “Recovery” in RO Systems? How to Balance Efficiency & Membrane Life?| Insights by AQUALITEK

Learn the key differences between flux and recovery in reverse osmosis (RO) systems, and discover how to optimize both for better energy efficiency, lower operating cost, and reduced membrane fouling.

How to Reuse RO Wastewater — Smart and Sustainable Ways to Save Water| Insights by AQUALITEK

RO systems produce wastewater during filtration, but this water doesn’t have to go to waste. Learn the best methods to reuse RO reject water safely and sustainably for household and non-potable applications.

Is Replacing the Filter in an RO Water Purifier Complicated? Can You Do It Yourself?| Insights by AQUALITEK

Learn whether you can replace RO water purifier filters on your own, how difficult the process is, and what precautions to take. A complete step-by-step guide to help you perform safe, effective filter replacement at home.

Why You Should Drain the Water After Installing or Replacing a Filter Cartridge| Insights by AQUALITEK

Find out why it’s necessary to drain or flush your water purifier for a period after installing or replacing a new filter cartridge. Learn how this step ensures clean, safe, and great-tasting water while protecting your RO system and health.

How Often Should You Replace Each Filter Cartridge in an RO Water Purifier?| Insights by AQUALITEK

Understand how often to replace each filter cartridge in your RO water purifier and what factors determine replacement. Learn whether replacement should be based on time, water volume, or water quality to keep your system performing at its best.

What Is the Wastewater Ratio and Why RO Systems Produce Wastewater| Insights by AQUALITEK

Learn what the wastewater ratio means in reverse osmosis (RO) systems, why wastewater is generated during filtration, and how to optimize your RO system’s efficiency to reduce water loss and save costs.

Functions of Pre-Filters (PP Cotton and Activated Carbon) and Their Relationship with the RO Membrane| Insights by AQUALITEK

Learn about the key roles of pre-filters like PP cotton and activated carbon in reverse osmosis (RO) systems. Discover how they protect the RO membrane, improve purification efficiency, and extend the lifespan of your water purifier.

Environmental Risks and Proper Disposal of Byproducts from Water Treatment| Insights by AQUALITEK

Learn about the environmental risks associated with byproducts generated during water treatment—such as disinfection byproducts, spent activated carbon, and discarded membrane modules—and discover proper management and disposal strategies for sustainable water purification.

Environmental Impact and Treatment Methods of Brine from Membrane Processes| Insights by AQUALITEK

Understand the environmental challenges posed by brine generated in membrane-based water treatment systems such as RO and NF. Learn about sustainable and cost-effective methods for brine management, treatment, and disposal.

Understanding Offline Cleaning and Online Cleaning in Membrane Systems| Insights by AQUALITEK

Learn the difference between offline cleaning and online cleaning in membrane filtration systems—when to use each, how they work, and how proper cleaning strategies can extend membrane lifespan and maintain high filtration performance.

Mainstream Technologies for Seawater Desalination — Costs and Environmental Impacts| Insights by AQUALITEK

Explore the leading technologies in seawater desalination, including Reverse Osmosis (RO), Multi-Stage Flash (MSF), and Multi-Effect Distillation (MED). Learn their advantages, costs, and environmental impacts to understand which solution best fits sustainable water production.

Best Guide: What Is Forward Flush (Flush Mode) in RO Water Purifiers and Why It Matters| Insights by AQUALITEK

Learn what “forward flush” or “flush mode” means in RO water purifiers, how it works, and why it’s essential for maintaining filtration efficiency, prolonging membrane life, and ensuring clean, safe drinking water.

Best Guide: How to Maximize Membrane Performance by Optimizing the Backwash Process| Insights by AQUALITEK

Learn how to optimize the backwash process in membrane filtration systems—covering backwash intensity, duration, frequency, aeration, and chemical cleaning—to maximize membrane performance, reduce fouling, and extend lifespan.

Effective Cleaning Methods for Different Types of Membrane Fouling: FAQs & Expert Tips| Insights by AQUALITEK

Learn the most effective cleaning techniques for inorganic scaling, organic fouling, and biological fouling in membrane systems. Optimize your water treatment process with our expert tips.

Why Ultrafiltration Is Preferred Over Traditional Multimedia Filtration in Seawater Desalination Pretreatment| Insights by AQUALITEK

Discover why ultrafiltration is increasingly used instead of traditional multimedia filtration in seawater desalination pretreatment. Learn about its advantages and role in ensuring membrane protection.

Best Adsorption and Filtration Materials Beyond Activated Carbon: Functions and Pollutant Removal Explained| Insights by AQUALITEK

Explore the best adsorption and filtration materials beyond activated carbon, including molecular sieves, activated alumina, zeolite, ion exchange resin, and silica gel. Learn how each material works and what pollutants they effectively remove in water treatment applications.

Best Explanation: Why the Recovery Rate in Reverse Osmosis Systems Must Be Strictly Controlled| Insights by AQUALITEK

Learn why recovery rate control is critical in reverse osmosis (RO) systems, how excessive recovery affects membrane performance, and what problems can occur if the recovery rate is set too high. Understand the balance between water efficiency and system protection.

How to Choose the Right Filtration Solution for Different Water Needs| Insights by AQUALITEK

Learn how to choose the most suitable filtration system for various water needs — from direct drinking to whole-home purification and softened water. Understand key technologies like activated carbon, ultrafiltration, reverse osmosis, and water softeners for optimal water quality.

Why Filter Media Are Arranged in Tiers Based on Particle Size in Multi-Media Filters| Insights by AQUALITEK

Learn why multi-media filters (such as sand filters) arrange filter materials in layers according to particle size. Discover how this design enhances filtration efficiency, prevents clogging, and ensures consistent water quality for residential, commercial, and industrial systems.

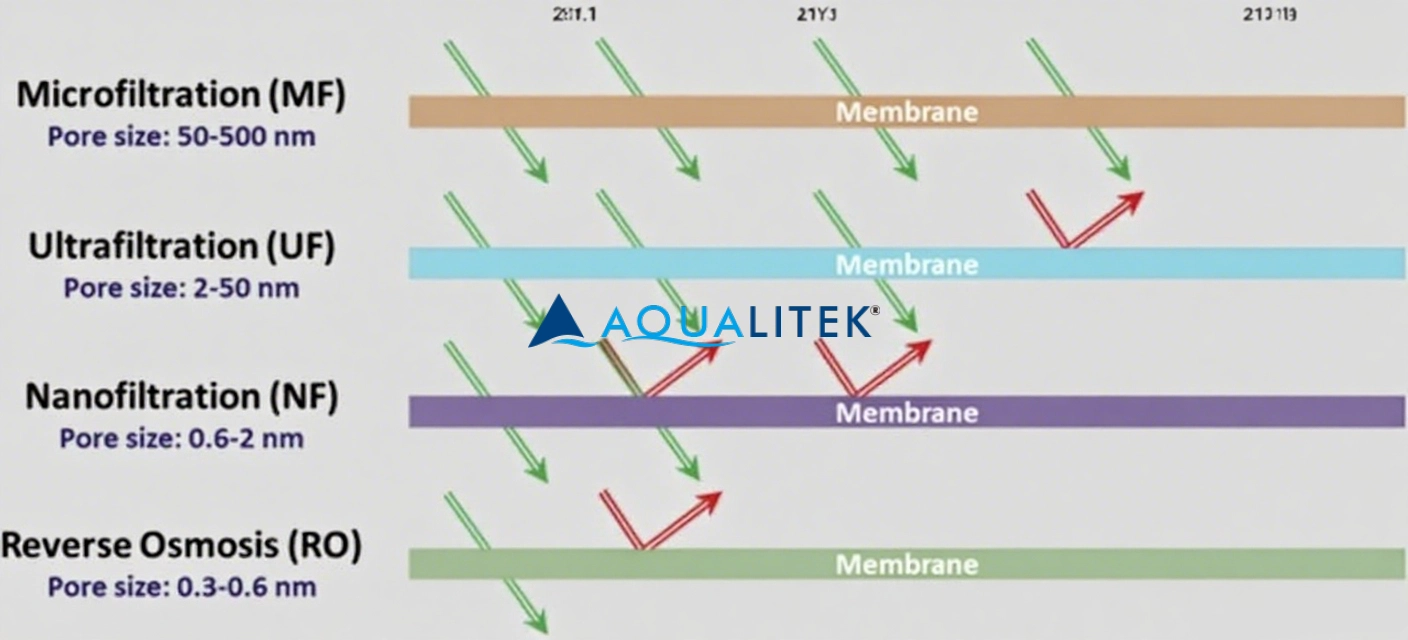

The Main Categories of Common Filtration Methods from Low to High Precision| Insights by AQUALITEK

Learn the key categories of water filtration methods arranged from low to high precision — from simple mechanical filters to advanced reverse osmosis and nanofiltration. Discover how each filtration stage improves water quality for residential, commercial, and industrial applications.

Unique Features of Nanofiltration Membranes Between Ultrafiltration and Reverse Osmosis| Insights by AQUALITEK

Discover the unique features of nanofiltration membranes — a key technology positioned between ultrafiltration and reverse osmosis. Learn how nanofiltration balances precision, energy efficiency, and selective ion removal in modern water treatment systems.

Best Solutions for Hard Water: Causes, Problems, and Effective Softening Methods| Insights by AQUALITEK

Discover the major problems caused by high water hardness and explore the best water softening methods, including ion exchange, reverse osmosis, and salt-free systems for homes and industries.

Best Guide to Activated Carbon Adsorption: What It Removes and When to Regenerate or Replace It| Insights by AQUALITEK

Learn what pollutants activated carbon removes from water and when it should be regenerated or replaced. Explore how carbon filters improve water quality in residential, commercial, and industrial applications.

How Much Water Do Treatment Systems Waste? Understanding Efficiency in UF and Other Filtration Technologies| Insights by AQUALITEK

Discover how much water treatment systems waste, especially ultrafiltration (UF) systems. Learn what affects wastewater ratios, how to improve efficiency, and the best practices to minimize water loss in purification systems.

What is the Treatability Index of Wastewater? Understanding Its Meaning and Importance| Insights by AQUALITEK

Learn what the Treatability Index of wastewater means, how it is calculated, and why it’s essential for designing effective water treatment systems. Discover factors affecting treatability and how to improve wastewater management efficiency.

What is Ultrafiltration and How Does It Work?| Insights by AQUALITEK

Aqualitek ultrafiltration explains what ultrafiltration is and how it works for reliable drinking water purification UF and efficient wastewater recycling UF solutions by AQUALITEK. Learn benefits, applications, and system design.

Ultrafiltration Process and How Different Types Work | Aqualitek UF Systems

Can Wastewater Be Used for Irrigation?| Insights by AQUALITEK

Discover wastewater irrigation with AQUALITEK: expert insights on sustainable irrigation, wastewater reuse benefits, treatment solutions and safe application to enhance water security and crop yields.

Water Recovery from Urban Wastewater for Irrigation Using Ultrafiltration| Insights by AQUALITEK

Discover AQUALITEK insights on water recovery from urban wastewater for irrigation using ultrafiltration. Learn ultrafiltration wastewater treatment methods for sustainable wastewater reuse and resilient urban irrigation.

How Do I Know If My RO Membrane Needs Replacing?| Insights by AQUALITEK

AQUALITEK explains RO membrane replacement: symptoms, tests and clear guidance on when to replace RO membrane. Learn about RO filter lifespan, performance loss and maintenance tips to extend membrane life.

What Is the Main Difference Between Osmosis and Reverse Osmosis?| Insights by AQUALITEK

Can I Drink RO Water Directly?| Insights by AQUALITEK

Can I Drink RO Water Directly? AQUALITEK explains if RO water is safe to drink, benefits of reverse osmosis drinking water, and practical tips to ensure safe drinking water at home.

How to Make Reverse Osmosis (RO) Water Safe to Drink?| Insights by AQUALITEK

Learn practical tips to make RO water healthy by remineralization of RO water and filtration upgrades. Improve reverse osmosis water taste, safety and mineral balance with AQUALITEK insights.

Best Guide: What Type of Water is Used for Reverse Osmosis? | Insights by AQUALITEK

Discover the best type of water for reverse osmosis (RO) systems.Learn how different water sources-tap,brackish,seawater,and well water-after performance,system design,and purification efficiency.

Can You Drink Ocean Water If You Desalinate It? Best Guide to Safe Drinking

Can you drink ocean water if you desalinate it? AQUALITEK explains desalination drinking water methods, answers desalinated water safe concerns, and guides safe steps, risks and best practices for potable use.

How to Know If Your Water Is Pure? 5 Best Methods for Accurate Testing at Home

Unsure about your water quality? This definitive guide reveals the 5 best methods to test if your water is pure, from simple DIY checks to professional lab analysis. Ensure your safety today!

Best Guide to the Difference Between RO, NF, and UF Membrane Filtration

Discover the difference between RO (Reverse Osmosis), NF (Nanofiltration), and UF (Ultrafiltration). Learn how each membrane works, their applications, benefits, and which filtration technology is best for your water treatment needs.

Regional Expertise: Indonesia

Tailored Water Treatment Solutions for One of Asia’s Most Water-Challenged Nations

Indonesia’s Water Landscape: Rich in Sources, Strained by Demand

Despite high annual rainfall and vast river systems, Indonesia faces growing water scarcity and quality issues due to uneven distribution, pollution, and climate volatility.

Best Water Softener Systems for Home & Industry

Everything You Need to Know About Water Softeners & Softener Systems

Hard water can wreak havoc on plumbing systems, appliances, skin, and even energy bills. Despite being safe to drink, water with high mineral content (mainly calcium and magnesium) can be costly in the long run. That’s where a water softener or softener system comes in—transforming your water supply, extending appliance life, and improving daily comfort.

This guide dives deep into the world of water softening, exploring the science, system types, installation factors, and cutting-edge innovations behind modern softener systems. Whether you're a homeowner tired of soap scum or a facility manager facing scale buildup in industrial systems, this article is for you.

Top Sea Water Desalination Machines for Clean Water

Discover how sea water desalination machines work, the best types available, and how to choose the right system for homes, ships, or industrial use.

Top Water Treatment Plant Machinery & Trusted Suppliers

Discover advanced water treatment plant machinery and connect with reliable suppliers to ensure efficiency and sustainability in industrial water solutions.

What Is Hard Water? Causes, Effects & Solutions

Learn what hard water is, what causes it, its impact on your home and health, and how to treat it with softeners and filters. Complete expert guide.

Pure Water, Healthy Lives: The Power of Reverse Osmosis in Drinking Water Treatment

Access to clean, safe drinking water is a fundamental human right—yet millions worldwide still face challenges due to contamination, scarcity, and aging infrastructure. For industries and communities prioritizing water quality, reverse osmosis (RO) technology has emerged as a gold standard for producing pure, reliable drinking water. At Aqualitek, we specialize in designing and delivering advanced RO systems tailored to meet the highest standards of safety, efficiency, and sustainability.

Got Questions? We’re Here to Help

Feel free to submit your questions, feedback, or information requests here. Whether you need technical support, product materials, or industry insights, we’re happy to connect and share.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

By clicking "Submit now," I agree to your processing of my personal data.

To see how to withdraw your consent, how to control your personal data, and how we process it, please see our Privacy Policy and Terms of Use.

+86 139 2235 7065

Tel

+86 139 2235 7065

Address

No.63, JieYuan Rd. Panyu district, Guangzhou city, Guangdong province, China

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo