What Is an Energy Recovery Device (ERD) and Why Is It Essential in Seawater Desalination RO Systems?| Insights by AQUALITEK

Energy Recovery Devices (ERDs) play a critical role in seawater reverse osmosis (SWRO) systems by capturing and reusing high-pressure energy from concentrated brine. This dramatically reduces power consumption, improves membrane performance, and lowers the cost of desalination. This article explains working principles, types of ERDs, and includes technical diagrams for system engineering reference.

- Introduction

- Detailed Content

- ✅ 1. Why ERD Is Critical in Seawater RO Systems

- ✅ 2. How ERDs Work — Core Principle

- Main ERD Technologies + Flow Diagrams

- ⭐ Isobaric Chamber ERD (PX Pressure Exchanger)

- ⭐ Turbocharger Type ERD

- PX vs Turbocharger ERD — Selection Guide

- Engineering Integration Recommendations

- System Design Considerations

- Conclusion

Introduction

Seawater desalination requires extremely high pressure (typically 55–70 bar) to overcome osmotic pressure and drive water through RO membranes. This makes energy consumption the primary operating cost (up to 40–50% of total).

To solve this challenge, modern SWRO systems are equipped with Energy Recovery Devices (ERDs) — a breakthrough technology that recovers hydraulic energy from high-pressure brine concentrate and transfers it back into the feedwater system.

With ERDs, energy usage can be reduced by up to 50%, making seawater desalination economically and environmentally feasible.

Detailed Content

✅ 1. Why ERD Is Critical in Seawater RO Systems

Seawater has high osmotic pressure and requires:

•55–70 bar for RO desalination

•Energy consumption 35–45% from high-pressure pumping

Without ERD → power consumption skyrockets to 5–6 kWh/m³

✅ With ERD → energy consumption reduced to 2.5–3.5 kWh/m³

|

Engineering Benefit |

Impact |

|

Reduce energy cost by 30–50% |

Major OPEX improvement |

|

Reduce required high-pressure pump size |

Lower CAPEX investment |

|

Improve system recovery & throughput |

Higher productivity |

|

Reduce CO₂ emissions |

Better sustainability and ESG performance |

|

Extend membrane and pump life |

Lower maintenance cost |

A modern SWRO plant cannot be competitive without ERD technology.

✅ 2. How ERDs Work — Core Principle

High-pressure brine leaving RO retains ~97% of pump energy ⚡

ERD recovers this energy and returns it to incoming seawater → boosting pressure.

Benefits:

•Reduces energy cost and carbon footprint

•Allows smaller high-pressure pumps

•Enhances membrane lifespan and stability

Main ERD Technologies + Flow Diagrams

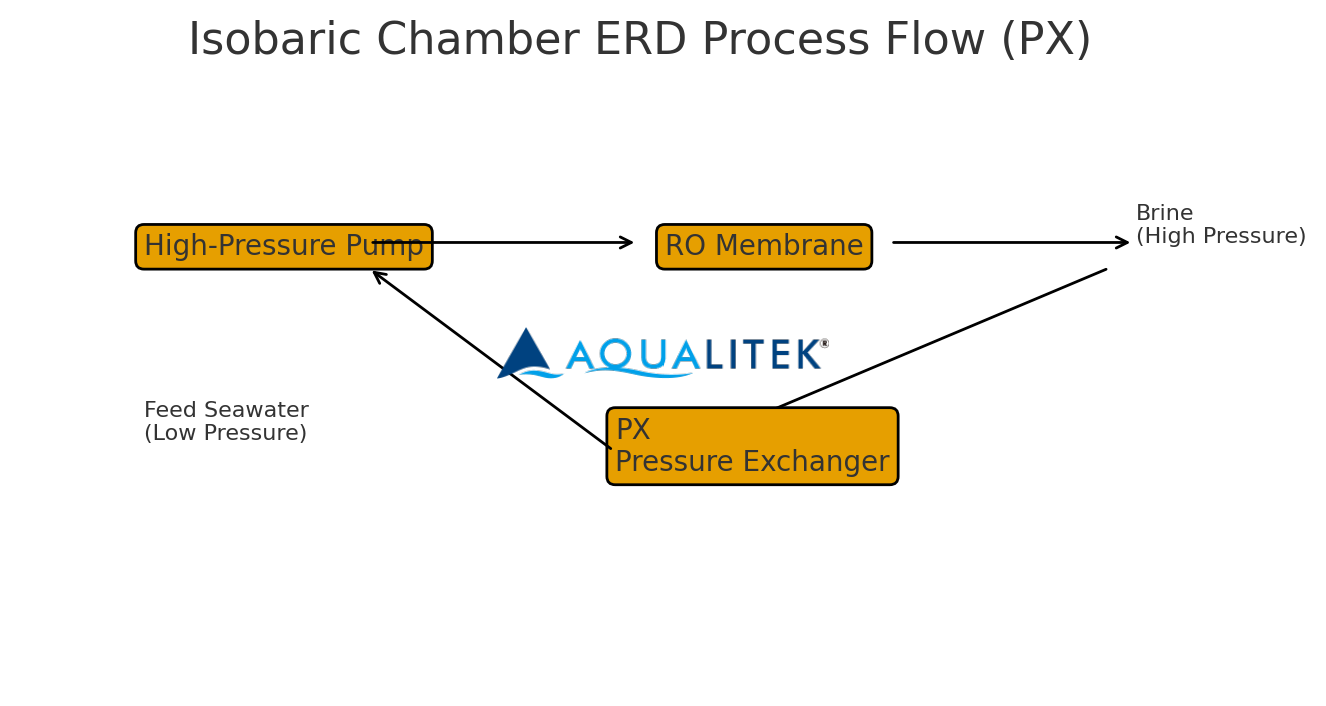

⭐ Isobaric Chamber ERD (PX Pressure Exchanger)

Features

|

Attribute |

Performance |

|

Energy Recovery Rate |

✅ 95–98% |

|

Efficiency under varying flow |

✅ Very high |

|

Mechanical wear |

Very low |

|

Cost |

Medium |

Flow Diagram

✅ Isobaric Chamber ERD Process Flow (PX)

✅ Isobaric Chamber ERD Process Flow (PX)

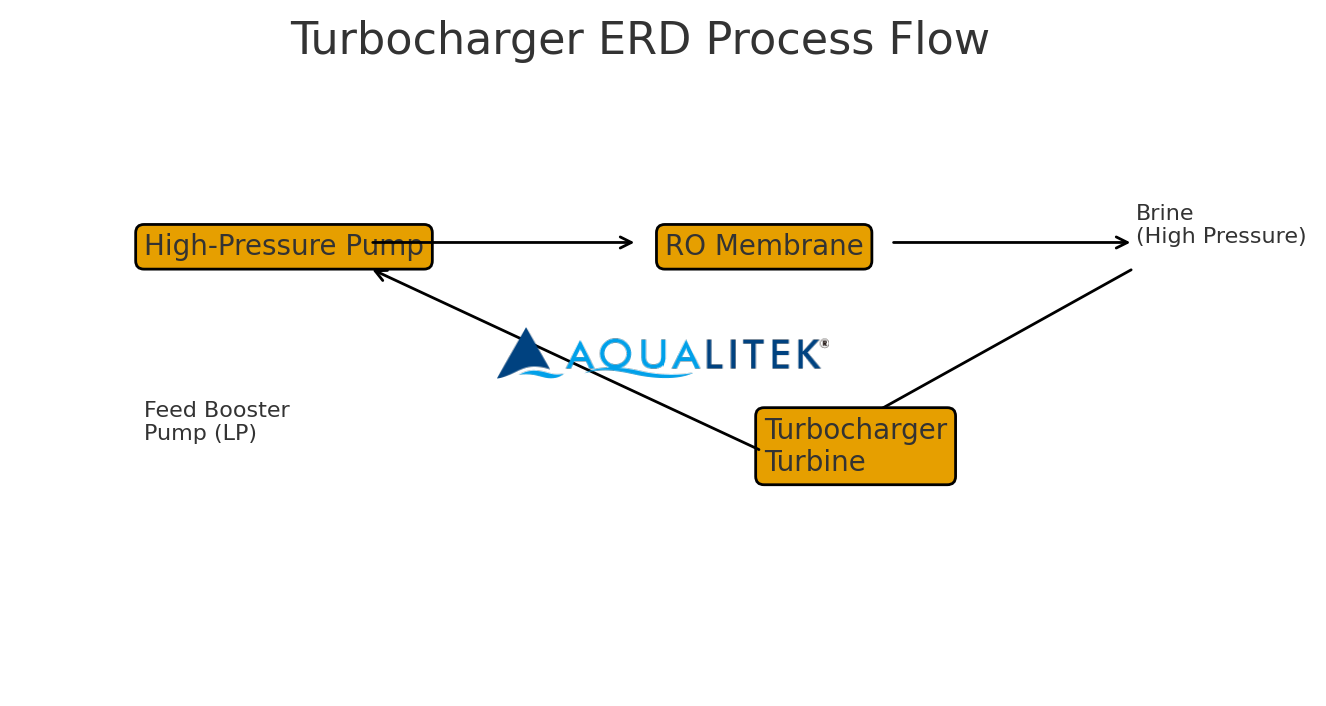

⭐ Turbocharger Type ERD

Features

|

Attribute |

Performance |

|

Energy Recovery Rate |

75–90% |

|

Moving parts |

More → maintenance required |

|

Cost |

✅ Lower than PX |

|

Best Application |

Small–mid capacity SWRO |

Flow Diagram

✅ Turbocharger ERD Process Flow

✅ Turbocharger ERD Process Flow

PX vs Turbocharger ERD — Selection Guide

|

Item |

PX (Pressure Exchanger) |

Turbocharger |

|

Efficiency |

⭐⭐⭐⭐⭐ |

⭐⭐⭐⭐ |

|

System size |

Medium/Large |

Small/Medium |

|

Flow stability |

Excellent |

Moderate |

|

Cost |

Medium |

Low |

|

Lifecycle |

25+ years |

10–15 years |

✅ PX dominates modern SWRO plants

✅ Turbo suits compact systems and budget-limited projects

Engineering Integration Recommendations

For large desalination plants:

•Use PX ERD + high-pressure pump

•Maintain stable brine pressure to ensure chamber sealing

For variable-flow or seasonal operations:

•Consider hybrid: PX + Turbo to stabilize low-load condition

Maintenance Keys

•Monitor pressure differential

•Regular brine check (clean, low particle loading)

•Avoid air ingress to prevent efficiency drop

System Design Considerations

To maximize ERD performance in SWRO engineering:

✔ Match flow capacity with brine discharge

✔ Stable operating pressure (avoid fluctuations)

✔ Minimize energy losses through piping design

✔ Integrate VFD controls for smooth regulation

✔ Maintain feed salinity and SDI stability

→ Correct ERD selection directly influences LCC (Life Cycle Cost), system availability, and long-term stability.

Conclusion

ERDs are not optional in seawater RO — they are essential for:

✅ Energy savings

✅ Reduced operating cost

✅ Longer membrane life

✅ Improved sustainability

PX-type ERDs have become the industry standard for high-efficiency desalination systems worldwide.

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo