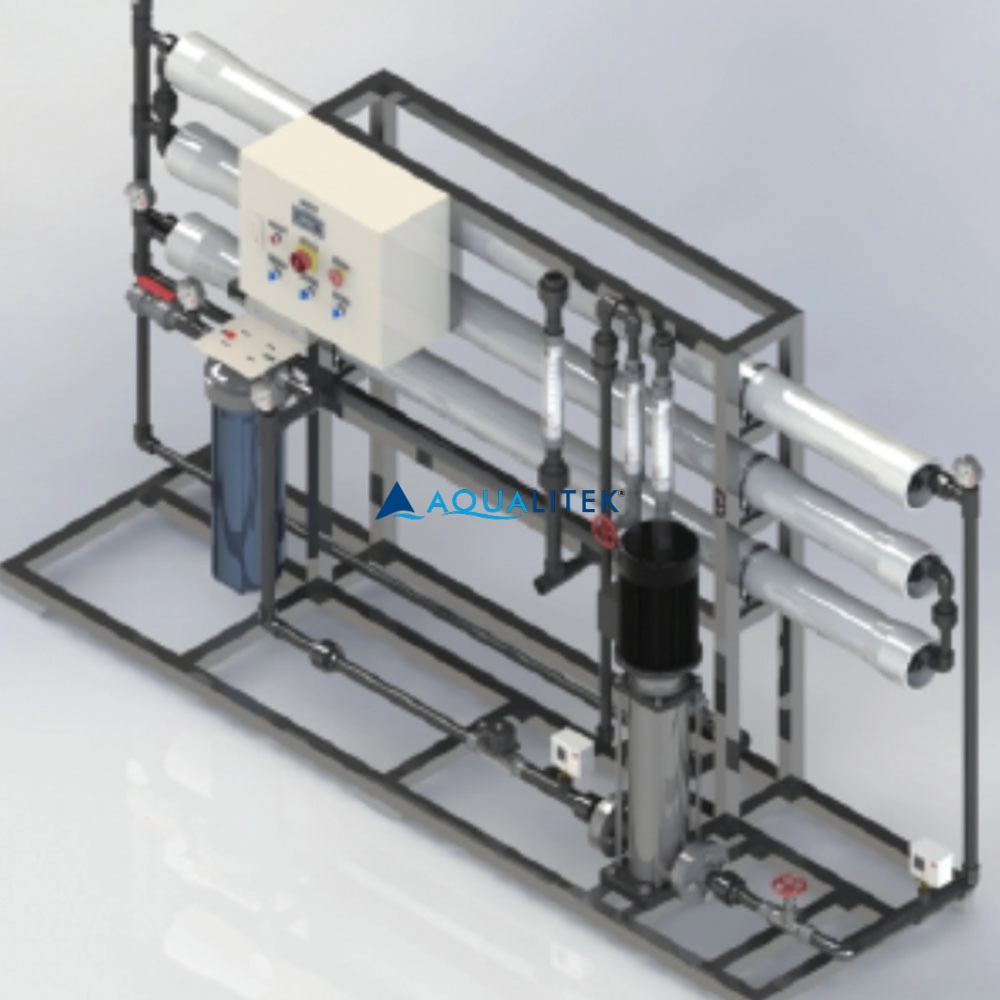

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Description

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Features

Backflow to increase the recovery rate

✔️ Low & high pressure protection switches

✔️ TDS/conductivity and pressure gauges

✔️ Powder-coated mild steel skid (rust-proof)

✔️ Automatic membrane flushing system

✔️ Smart electrical control panel with interlocks

Technical sheet

|

Specification |

Details |

|

Model |

TWV-412 |

|

Capacity |

500 LPH (≈12 m³/day) |

|

Recovery Rate |

40–60% (feed water dependent) |

|

Salt Rejection |

96–99% |

|

RO Membranes |

4040 * 2 (in series) |

|

Max Feed Water TDS |

Up to 1500 ppm (higher optional) |

|

Operating Pressure |

5–10 bar |

|

High Pressure Pump |

1.1kw /1.5HP |

|

RO controller |

Auto control C-5TM |

|

Pretreatment optional |

Sand filter + Carbon filter + water softener Or other filters if needed |

|

Electrical Supply |

110V/220V/380V, 50Hz/60hz |

|

Skid Frame |

Powder-coated MS or SS304 |

Available Options

PLC + HMI touch screen control system

Online monitoring (pH, ORP, flow, TDS)

Dosing systems: antiscalant, chlorine, SMBS

CIP (Clean-in-Place) system for membrane washing

UV sterilizer or Ozonation unit

Stainless steel piping upgrade

Variable Frequency Drive (VFD) for energy saving

Product water storage tank with level sensors

Applications

💧 Drinking Water – schools, hotels, offices, communities

💧 Food & Beverage – production and processing lines

💧 Pharmaceutical & Healthcare – purified process water

💧 Electronics & Semiconductor – high-purity water use

💧 Industrial Utilities – boiler feed, cooling tower make-up

💧 Commercial Bottling Plants – packaged drinking water

We can tailor this 500 LPH RO System with automation, monitoring, or additional disinfection modules to meet your exact water treatment needs.

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

TWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for tap water (lower TDS). The large volumes can help meet your a variety of industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

BWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type)for brackish water(higher TDS).The medium large volumes can help meet your a variety of industrial and commercial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Get Expert Solutions with Our Professional Water Treatment Systems

Tell us your needs, and our engineering team will provide tailored product recommendations to optimize your water quality.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

By clicking "Submit now," I agree to your processing of my personal data.

To see how to withdraw your consent, how to control your personal data, and how we process it, please see our Privacy Policy and Terms of Use.

+86 139 2235 7065

Tel

+86 139 2235 7065

Address

No.63, JieYuan Rd. Panyu district, Guangzhou city, Guangdong province, China

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo