What Are the Criteria for Replacing the Filter Cartridge of a Pre-Filter? (Expert RO System Guide)| Insights by AQUALITEK

Learn the clear and practical criteria for replacing pre-filter cartridges such as PP cotton, activated carbon, and composite filters. This expert guide explains visual signs, pressure changes, taste issues, RO protection needs, and time-based replacement rules.

- Introduction

- 1. Why Pre-Filter Replacement Matters

- 2. Replacement Criteria for Pre-Filter Cartridges

- Criterion 1: Drop in Water Flow or Pressure

- Criterion 2: Discoloration or Visible Dirt Accumulation

- Criterion 3: Unusual Taste or Odor in the Water

- Criterion 4: ORP or Chlorine Breakthrough (for RO Systems)

- Criterion 5: Usage Time Reached (Time-Based Rule)

- Criterion 6: SDI (Silt Density Index) Rising Significantly

- Criterion 7: System Alarms or Changes in Operating Parameters

- 3. Pre-Filter Replacement Frequency Overview

- 4. Why Timely Replacement Is Essential

- Conclusion

Introduction

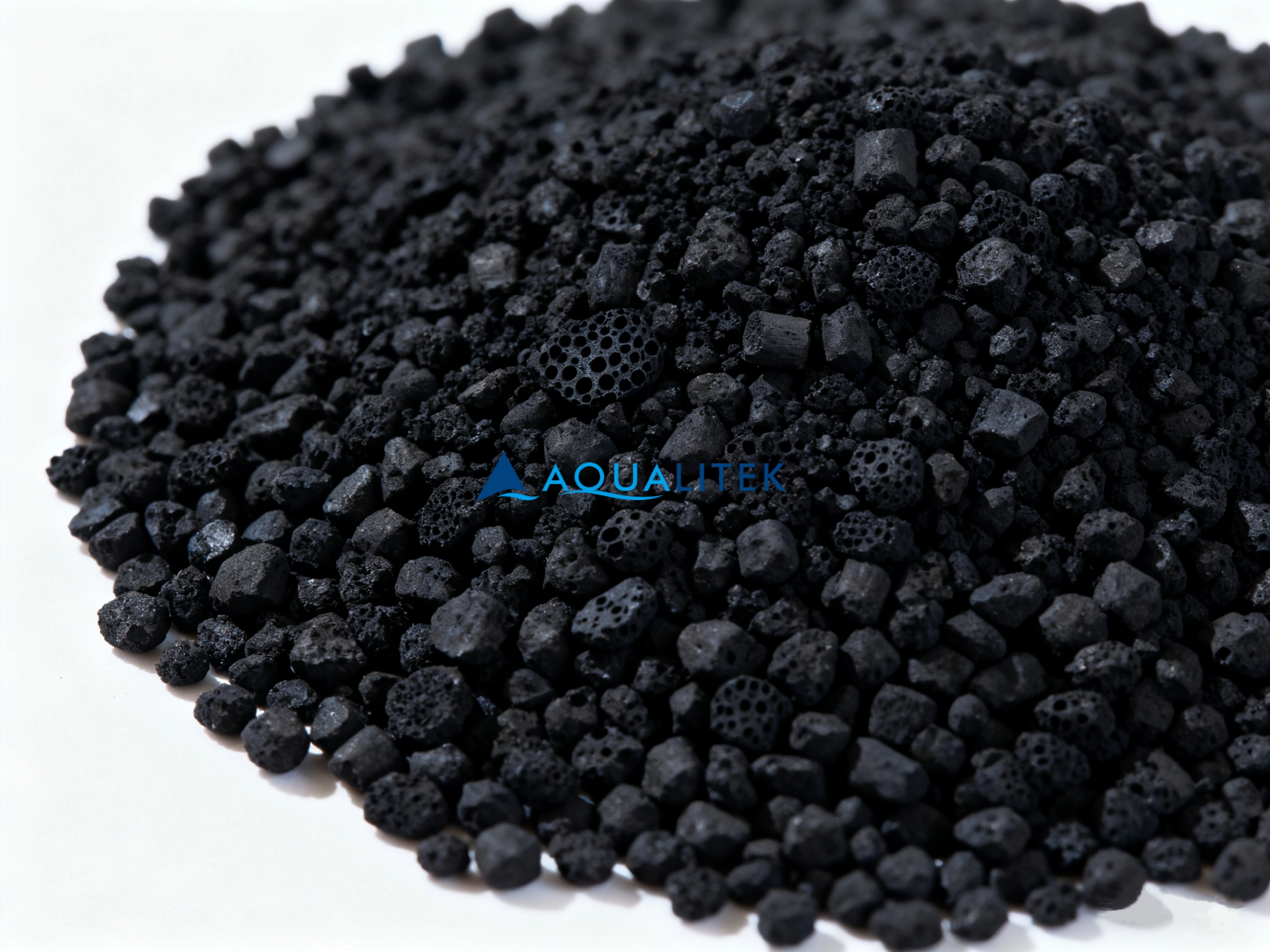

Pre-filters are the first line of defense in any RO or water purification system. Whether in household or industrial applications, PP sediment filters, granular activated carbon (GAC), carbon block filters (CTO), and composite cartridges protect the RO membrane from particulate fouling, chlorine oxidation, and organic contamination.

However, pre-filters are consumables. Knowing exactly when to replace them is essential not only for water quality but also for extending RO membrane life and preventing irreversible damage.

This Best-class guide delivers clear replacement criteria based on performance, visual inspection, pressure behavior, water quality, and operational conditions.

1. Why Pre-Filter Replacement Matters

Pre-filters protect the RO membrane by:

•Removing suspended solids and turbidity

•Adsorbing chlorine and organic compounds

•Reducing silt density index (SDI)

•Preventing membrane fouling and oxidation

Once overloaded, they lose effectiveness and can cause:

•RO membrane clogging

•Membrane chemical degradation

•Reduced system flow

•Increased energy consumption

•Poor-tasting water

Thus, timely replacement is critical.

2. Replacement Criteria for Pre-Filter Cartridges

Below are the universally accepted criteria used in both residential and industrial RO systems.

Criterion 1: Drop in Water Flow or Pressure

(1)Symptoms:

•Decreased outlet flow

•Lower pressure before RO

•Higher pressure differential across the pre-filter

(2)How to evaluate:

A pressure difference (ΔP) > 0.1–0.2 MPa typically indicates clogging for industrial setups.

For household systems, noticeable flow reduction is the primary indicator.

(3)Reason:

PP filters trap particles. As pores block, resistance increases.

If flow drops significantly, the pre-filter must be replaced immediately.

Criterion 2: Discoloration or Visible Dirt Accumulation

(1)Signs:

•PP filter turns brown, yellow, or black

•Carbon block surface becomes heavily polluted

•Filter slime or biofilm present

(2)Interpretation:

Discoloration means the filter is saturated.

Biofilm indicates microbial growth—replace immediately.

This method is especially useful for transparent pre-filter housings.

Criterion 3: Unusual Taste or Odor in the Water

Mainly applies to carbon filters (GAC/CTO).

(1)Indicators:

•Chlorine smell returns

•Water tastes “raw,” metallic, or earthy

(2)Cause:

Activated carbon is saturated and can no longer adsorb:

•Chlorine

•VOCs

•Odors

•Organic pollutants

This is a strong signal for replacement.

Criterion 4: ORP or Chlorine Breakthrough (for RO Systems)

(1)Industrial RO:

Monitoring ORP or free chlorine after the carbon filter tells you whether activated carbon is exhausted.

•Free chlorine > 0.05 mg/L after carbon = immediate replacement

•ORP > 250–300 mV often indicates insufficient dechlorination

(2)Reason:

Chlorine breakthrough is extremely dangerous because it causes irreversible RO membrane oxidation.

Criterion 5: Usage Time Reached (Time-Based Rule)

Typical recommended intervals:

(1)Household Pre-Filters:

•PP sediment filter: 3–6 months

•GAC carbon filter: 6–12 months

•CTO carbon block: 6–12 months

(2)Industrial Pre-Filters:

•PP cartridges: 1–3 months (depends on SDI)

•Activated carbon: 6–18 months

•Multimedia filters/backwashable systems: based on pressure and performance, not time alone

Time-based replacement prevents performance decline before issues appear.

Criterion 6: SDI (Silt Density Index) Rising Significantly

For RO systems, SDI is crucial:

•Ideal SDI entering RO: < 3

•If SDI > 5, pre-filters may be exhausted

•Rising SDI = PP/carbon filters not effectively removing particulates

Replace filters and stabilize pretreatment.

Criterion 7: System Alarms or Changes in Operating Parameters

Smart RO units or industrial PLC systems may alert based on:

•Pressure differential

•Flow tracking

•Filter life estimation

•Turbidity or quality monitoring

It must not be ignored—replace filters promptly.

3. Pre-Filter Replacement Frequency Overview

|

Filter Type |

Main Function |

Typical Replacement |

|

PP Sediment |

Remove particles |

1–6 months |

|

GAC Carbon |

Remove chlorine/organics |

6–12 months |

|

CTO Carbon |

Deep adsorption |

6–12 months |

|

Composite Filter |

Multiple functions |

6–12 months |

|

Industrial PP |

Protect RO/UF |

1–3 months |

|

Industrial Carbon |

Dechlorination |

6–18 months |

Actual frequency depends on:

•Source water quality

•Turbidity

•Total suspended solids

•Usage volume

•Pretreatment design

4. Why Timely Replacement Is Essential

Failing to replace pre-filters leads to:

•RO membrane fouling

•Chlorine breakthrough

•Shortened membrane lifespan

•Increased operating cost

•Pump overload and energy waste

•Poor water taste and quality

The cost of pre-filter replacement is small compared to membrane replacement, making preventive maintenance a high-value decision.

Conclusion

The criteria for replacing pre-filter cartridges are based on performance degradation (pressure, flow), visible conditions, water taste, chlorine breakthrough, SDI increase, and time. By following these standards, you ensure stable operation, protect expensive RO membranes, and maintain consistent water quality.

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

TWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for tap water (lower TDS). The large volumes can help meet your a variety of industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo