How Industrial RO Systems Integrate EDI or Mixed-Bed Ion Exchange for Ultrapure Water Production| Insights by AQUALITEK

Discover how industrial RO systems use EDI (electrodeionization) or mixed-bed ion exchange as polishing steps to produce ultrapure water, and understand the key design considerations for reliable water quality performance.

- RO + EDI / Mixed-Bed: The Ultimate Solution for Ultrapure Water

- Typical Ultrapure Water Process Flow

- Why 2-pass RO?

- Option 1: RO + EDI Integration (Continuous Polishing)

- How EDI Works

- Advantages

- Limitations

- Option 2: RO + Mixed-Bed Ion Exchange

- Advantages

- Limitations

- EDI vs. Mixed-Bed — How to Choose?

- Key Engineering Considerations

- Final Recommendation

RO + EDI / Mixed-Bed: The Ultimate Solution for Ultrapure Water

Industrial reverse osmosis (RO) systems are widely used to remove most dissolved ions from raw water. However, RO alone cannot achieve the extremely low conductivity requirements needed for ultrapure water applications, such as:

✅ Electronics & semiconductor manufacturing

✅ Power plant boiler feedwater

✅ Pharmaceutical & biotech production

✅ Precision chemical processing

To reach resistivity > 15–18 MΩ·cm, additional polishing purification is required:

➡️ EDI (Electrodeionization)

➡️ Mixed-bed ion exchange systems (MBIX/MB resin)

These technologies are integrated after RO to remove trace ions, silica, and TOC.

Typical Ultrapure Water Process Flow

Pretreatment → RO (1st Pass) → RO (2nd Pass) → EDI / Mixed Bed → Ultrapure Water Storage & Distribution

Why 2-pass RO?

✅ Greatly reduces TDS & CO₂

✅ Minimizes load on EDI/MBIX

✅ Improves overall system stability

Option 1: RO + EDI Integration (Continuous Polishing)

How EDI Works

Ion exchange resins + ion-selective membranes + DC electric field enable:

•Continuous ion removal

•No chemical regeneration required

•Constant production of ultrapure water

Advantages

✅ Continuous operation

✅ Lower operating cost (no chemicals)

✅ Stable product quality

✅ Small footprint, automation-friendly

Limitations

✖ Sensitive to feedwater quality

✖ CO₂, silica, hardness require strong pretreatment

Feedwater to EDI must have:

•Conductivity < 0.5–1.0 µS/cm

•Silica < 20–50 ppb

•Hardness ≈ 0 ppm

•SDI < 1–2

Best for: Electronics & pharmaceuticals

Option 2: RO + Mixed-Bed Ion Exchange

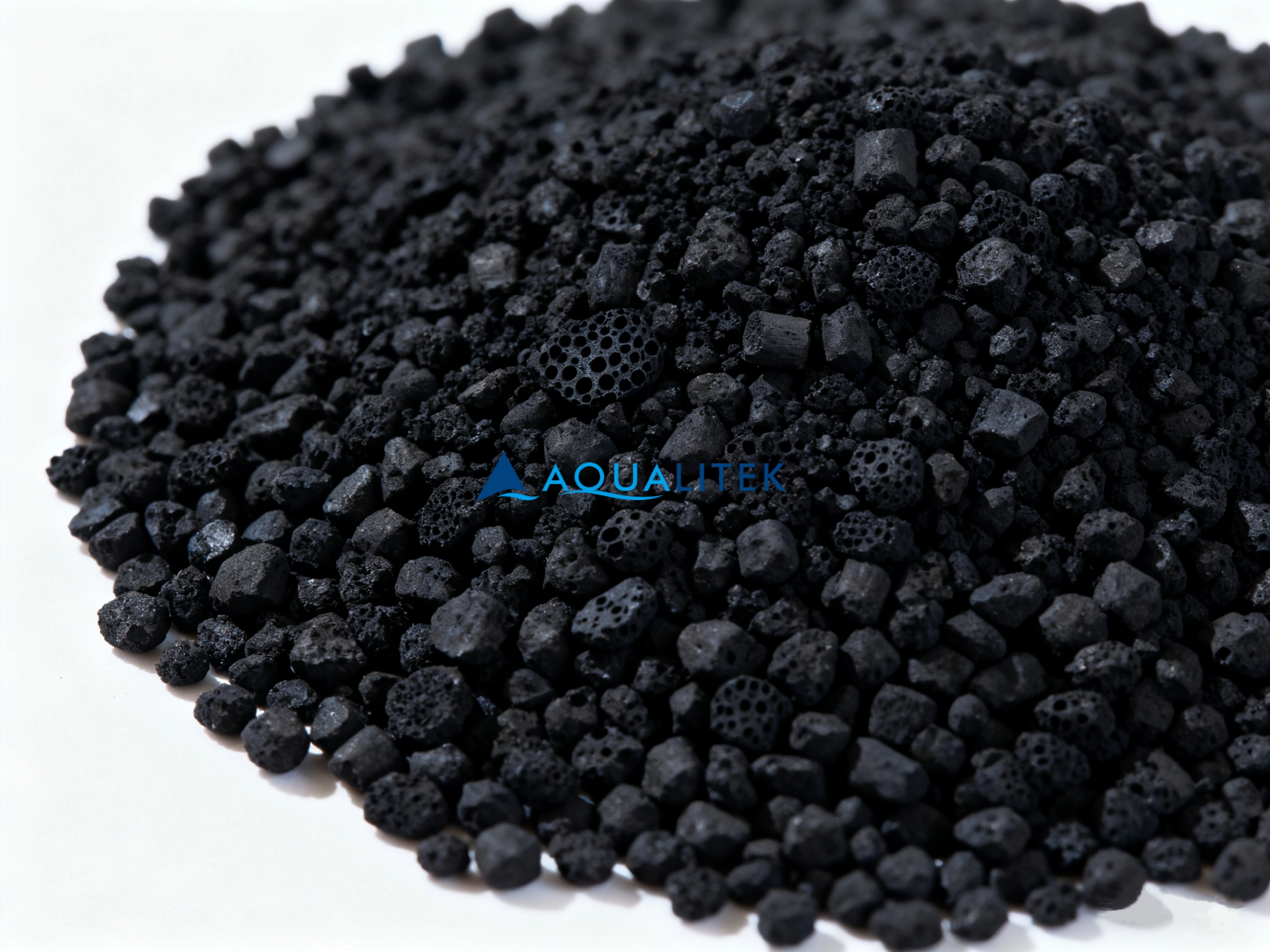

Mixed-bed systems use cation & anion resin to exchange residual ions.

Advantages

✅ Excellent polishing capability

✅ Capable of achieving 18.2 MΩ·cm

✅ Better tolerance to feedwater fluctuations

Limitations

✖ Requires periodic chemical regeneration

✖ High labor & chemical handling cost

✖ Wastewater discharge & environmental control needed

Best for:

•Power plants with high peak water demands

•Facilities prioritizing highest polishing performance

EDI vs. Mixed-Bed — How to Choose?

|

Factor |

EDI |

Mixed-Bed |

|

Operating Mode |

Continuous |

Batch |

|

Regeneration |

None |

Required |

|

Water Quality Stability |

High |

Very High |

|

Operating Cost |

Lower |

Higher |

|

Environmental Impact |

Low |

Chemical waste generated |

|

Sensitivity to Feedwater |

High |

Medium |

|

Common Use |

Electronics, pharma |

Power, critical ultrapure |

Hybrid systems are sometimes used:

RO → EDI → Mixed Bed

(For guaranteed ultra-low ions)

Key Engineering Considerations

|

Design Factor |

Recommendation |

|

CO₂ Removal |

Add degassing / membrane degasser after RO |

|

Silica Control |

Use pH adjustment + antiscalants |

|

TOC Reduction |

Activated carbon or UV TOC removal |

|

Continuous Monitoring |

Resistivity, pH, silica, sodium analyzers |

|

Material Selection |

UPVC, SS316L, or PVDF for purity piping |

✅ Proper post-treatment is essential to avoid contamination and guarantee system reliability.

Final Recommendation

To produce consistent ultrapure water:

Use 2-pass RO + EDI as the preferred solution,

supplemented by polishing mixed-bed when extreme purity requirements or peak flow buffering are needed.

This combination enables:

✔ Reliable 18.2 MΩ·cm purity

✔ Low total cost of ownership

✔ Stable and automated operation

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo