Essential Precautions Before Powering On a Newly Installed or Long-Term Unused RO System| Insights by AQUALITEK

Whether you are commissioning a newly installed reverse osmosis (RO) system or restarting one that has been idle for weeks or months, proper precautions are essential. RO membranes are highly sensitive, and improper startup can lead to irreversible fouling, oxidation, or mechanical damage.

- 1. Check All Piping, Valves, and Connections for Correct Installation

- Make sure to verify:

- Why this matters

- 2. Ensure System Flushing With Permeate or Clean Water

- Flushing removes:

- Procedure

- 3. Confirm Chlorine Removal — Residual Chlorine Must Be Zero

- Before startup, always test:

- 4. Check Pretreatment Filters and Water Quality

- Before startup, confirm:

- Why it matters

- 5. Remove Air Completely from the High-Pressure Pipeline

- Air removal steps

- 6. Start-Up Gradually — Never Apply Full Pressure Immediately

- Correct startup sequence

- Purpose

- 7. Discharge Initial Permeate — Do Not Use It

- Reasons to discard first 30–60 minutes of permeate

- 8. Verify Instrumentation and Controls

- Check the following:

- 9. Review Membrane Documentation and Operating Limits

- Typical membrane limits include:

- 10. Record Baseline Operation Data

- Conclusion

1. Check All Piping, Valves, and Connections for Correct Installation

Before powering the system:

Make sure to verify:

•All pipes and fittings are fully tightened

•No leaks on feed lines, permeate lines, or concentrate lines

•All manual valves are in the correct operating position

•No foreign materials or debris left inside pipelines

Why this matters

Incorrect piping or loose connections can cause sudden pressure loss, air entrainment, or water hammer, all of which can damage membranes or system components.

2. Ensure System Flushing With Permeate or Clean Water

For a new system or long-term standby system, flushing is mandatory.

Flushing removes:

•Preservative chemicals left inside the membranes

•Particles or dust from installation

•Stagnant water that may contain bacteria

Procedure

•Perform a low-pressure flush for 20–30 minutes

•Do not start the high-pressure pump during flushing

•Ensure flushing water fully replaces all storage or preservative water

3. Confirm Chlorine Removal — Residual Chlorine Must Be Zero

RO membranes (polyamide) are extremely sensitive to chlorine.

Before startup, always test:

•Residual chlorine = 0 mg/L

•ORP is within membrane manufacturer requirements

If chlorine is present, it may cause rapid membrane oxidation, permanently damaging the system.

4. Check Pretreatment Filters and Water Quality

Poor pretreatment is the most common cause of early membrane failure.

Before startup, confirm:

•PP filter, activated carbon filter, softener, sand filter, or multimedia filter are functioning properly

•SDI < 5

•Turbidity < 1 NTU

•Hardness and iron levels meet RO feed requirements

Why it matters

High SDI or turbidity can clog membranes within hours if not controlled before startup.

5. Remove Air Completely from the High-Pressure Pipeline

Air trapped inside the high-pressure line can cause water hammer, damaging membranes or housings.

Air removal steps

•Open vent valves on membrane housings

•Operate the feed pump at low speed to expel air

•Confirm a stable flow of water without bubbles

6. Start-Up Gradually — Never Apply Full Pressure Immediately

RO membranes must be pressurized slowly.

Correct startup sequence

1.Start with low-pressure circulation

2.Increase pressure gradually over 20–60 seconds

3.Stabilize at operating pressure after flow becomes steady

Purpose

•Protects membrane structure

•Prevents sudden pressure shocks

•Ensures uniform wetting of membrane surface

7. Discharge Initial Permeate — Do Not Use It

The initial permeate water is not suitable for use.

Reasons to discard first 30–60 minutes of permeate

•Residual preservative chemicals may be present

•Water quality may be unstable

•System needs time to reach steady salt rejection

8. Verify Instrumentation and Controls

Before powering on:

Check the following:

•Pressure gauges

•Flow meters

•Conductivity meters

•Low- and high-pressure switches

•PLC or control panel functions

Any malfunctioning instrument can lead to incorrect system behavior and potential damage.

9. Review Membrane Documentation and Operating Limits

Ensure the system is started within the membrane manufacturer’s limits.

Typical membrane limits include:

•Maximum pressure

•Maximum feed temperature

•pH limits for operation

•pH limits for cleaning

•Allowed chlorine concentration

Failure to follow these guidelines may void membrane warranty or cause premature failure.

10. Record Baseline Operation Data

After reaching stable operation, record:

•Feed pressure

•Permeate flow

•Concentrate flow

•System recovery

•Permeate conductivity

These baseline values help detect future issues early.

Conclusion

Powering on a new or long-inactive RO system requires careful preparation. By following proper flushing procedures, ensuring chlorine-free feed water, checking pretreatment conditions, removing air, and starting up gradually, you significantly reduce the risk of membrane damage and extend system lifespan.

These startup precautions are essential for ensuring long-term reliability, performance stability, and cost-effective operation.

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Introduction to Manganese Sand Filter

Manganese Sand Filter (MSF) is an efficient water filtration system specifically designed to remove iron, manganese, and hydrogen sulfide from water.

The filter utilizes a special manganese dioxide-coated sand media, which acts as an oxidizing agent to convert dissolved iron and manganese into solid particles, allowing them to be easily trapped and removed during the filtration process.

Manganese Sand Filters are commonly used in residential, commercial, and industrial water treatment applications where high levels of these contaminants are present. By improving water quality, preventing staining, and reducing unpleasant tastes and odors, Manganese Sand Filters provide a reliable and cost-effective solution for maintaining clean, clear, and safe water.

Introduction to Green Sand Filter (GSF)

Green Sand Filter (GSF) is an effective water filtration system designed to remove iron, manganese, and hydrogen sulfide from water. Utilizing a specially treated green sand media, this filter works through the process of oxidation and adsorption, where impurities are trapped within the filter media, ensuring clean, clear water. Green Sand Filters are widely used in both residential and industrial applications where water contains high levels of iron and other minerals that can cause staining, unpleasant odors, and corrosion. By providing an efficient and cost-effective solution for water purification, Green Sand Filters help protect plumbing systems, appliances, and enhance water quality for various applications.

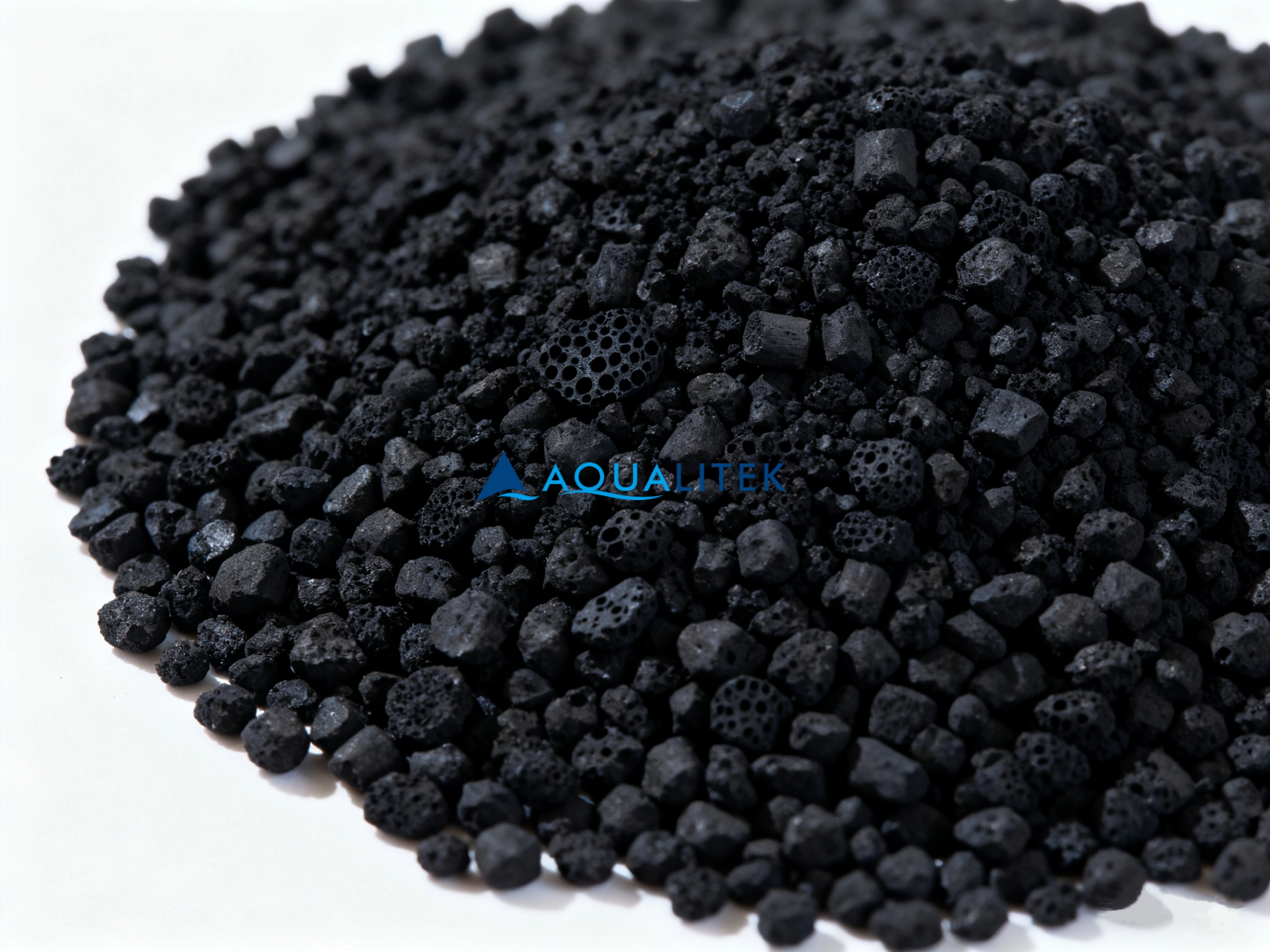

Activated Carbon Filter (ACF)

Our Activated Carbon Filter (ACF) is a highly effective water filtration system designed to remove chlorine, organic compounds, unpleasant odors, and harmful contaminants from water. Utilizing activated carbon’s high adsorption capacity, ACFs efficiently trap and eliminate impurities, improving taste, color, and overall water quality. These filters are widely used in industrial, commercial, and residential applications, serving as a critical pre-treatment step for processes like reverse osmosis (RO) and drinking water purification. With their ability to enhance water safety and meet stringent quality standards, Activated Carbon Filters play a vital role in various water treatment systems.

Copyright © 2025 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo