How to Select High-Pressure Pumps for Industrial Reverse Osmosis (RO) Systems| Insights by AQUALITEK

This guide explains the key types of high-pressure pumps used in industrial RO systems—centrifugal pumps and plunger (positive displacement) pumps. It covers performance characteristics, selection criteria, and best application scenarios to help engineers achieve high efficiency, stability, and cost-effectiveness in RO water treatment design.

Introduction

High-pressure pumps are the core driving force of industrial RO systems. They supply sufficient pressure to overcome osmotic pressure and push water through RO membranes—determining system energy consumption, recovery, and long-term reliability. Choosing the right pump ensures stable permeate flow, reduces membrane fouling, and lowers operating cost.

Among many models, centrifugal pumps and plunger pumps are the most commonly applied in RO projects. Below is a comprehensive comparison and selection guide.

Common High-Pressure Pump Types for RO Systems

1️⃣ Centrifugal Pumps

Working principle: Convert rotational energy into fluid pressure via impellers.

Pressure range: Medium to high

Flow range: Medium to large

✔ Advantages

•Continuous and stable flow

•Low vibration and quiet operation

•Simple structure → easier maintenance

•Lower investment cost

•Widely available spare parts

✖ Disadvantages

•Efficiency decreases when operating off the design point

•Limited maximum pressure compared with plunger pumps

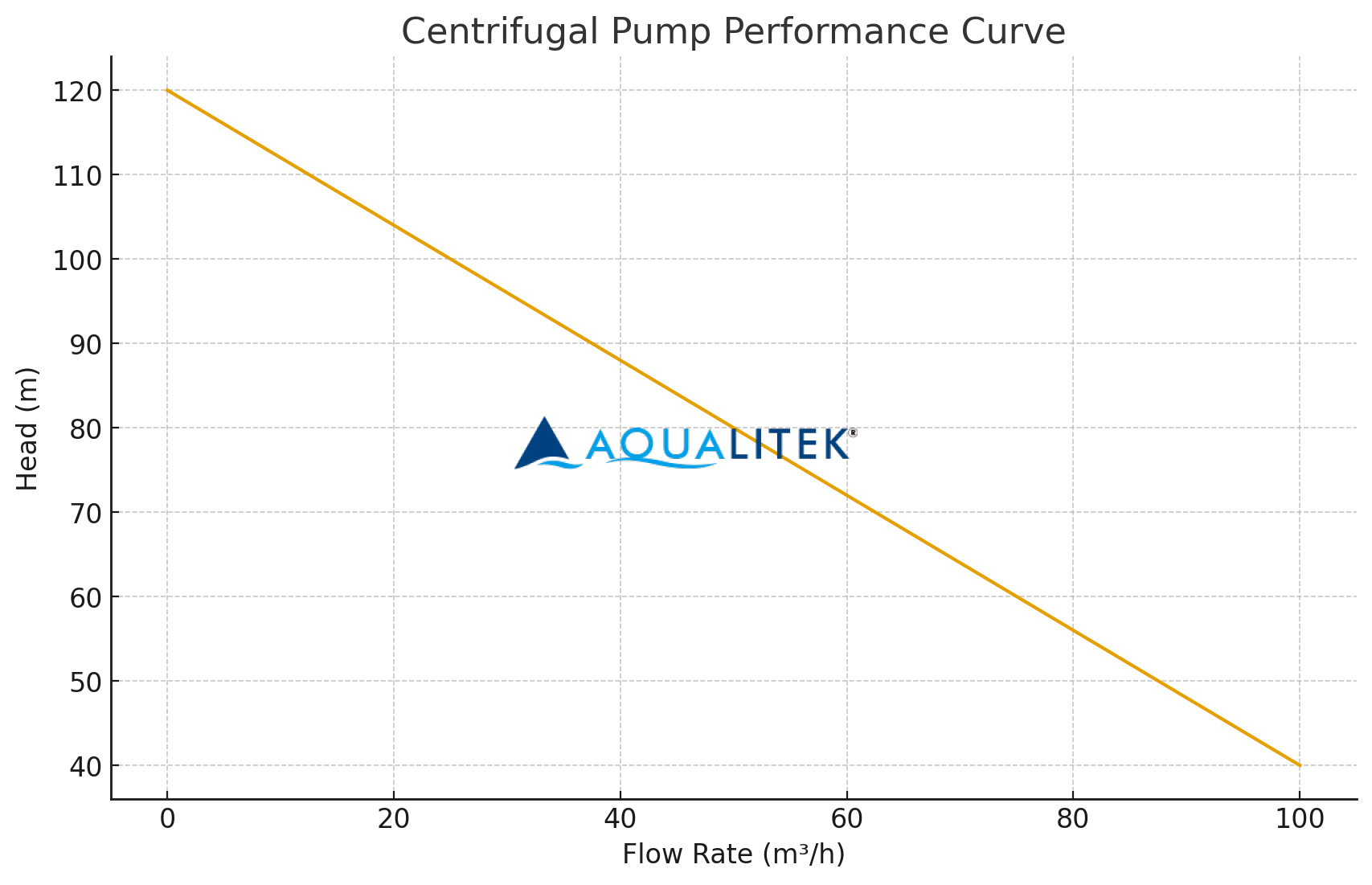

Centrifugal Pump Performance Curve

You can see the head decreases as flow increases, which means it is suitable for higher flow but medium-pressure RO applications.

Best applications:

•Brackish water RO (BWRO)

•Large municipal / industrial pure water systems

•Constant-flow desalination projects

2️⃣ Plunger Pumps (Positive Displacement)

Working principle: Reciprocating plungers apply direct pressure.

Pressure range: Very high

Flow range: Low to medium

✔ Advantages

•Very high pressure output → ideal for seawater RO

•High mechanical efficiency

•Precise pressure control (good under fluctuating feedwater)

✖ Disadvantages

•Pulsating flow → requires pulsation dampeners

•Higher vibration + maintenance cost

•Lubrication issues → risk of contamination in ultra-pure water applications

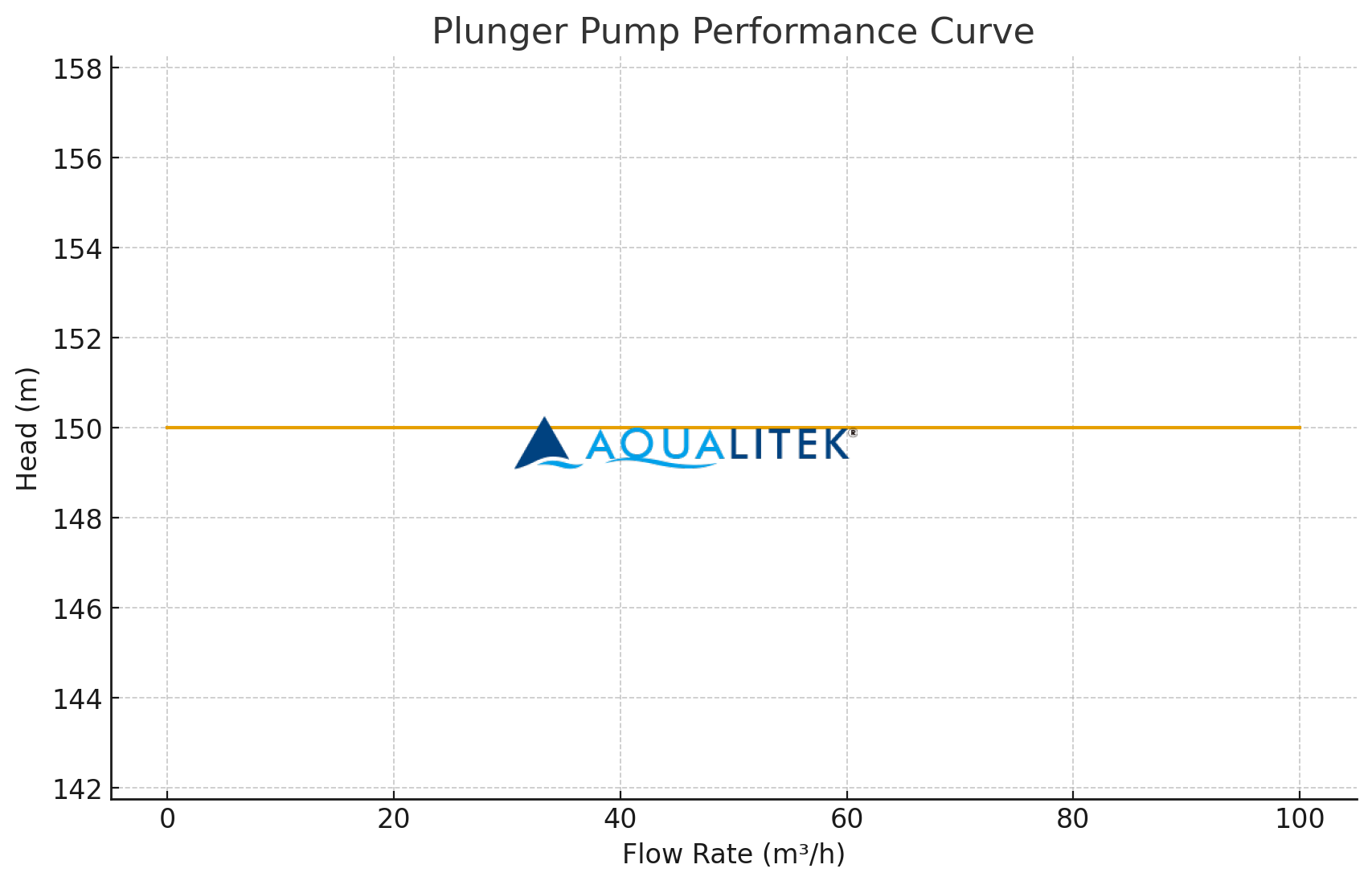

Plunger Pump Performance Curve

The head remains nearly constant across the flow range, making it ideal for high-pressure and seawater desalination RO systems.

Best applications:

Best applications:

•Seawater desalination (SWRO)

•High-salinity or high-pressure industrial wastewater

•Small and high-pressure specialized systems

Pump Selection Criteria for RO System Design

|

Selection Factor |

Engineering Objective |

Recommended Pump |

|

Pressure requirement |

Overcome osmotic pressure + membrane pressure drop |

High pressure → Plunger |

|

Feed salinity |

SEAWATER vs. tap/brackish |

SWRO → Plunger |

|

System scale |

Capacity & redundancy |

Large flow → Centrifugal |

|

Water quality stability |

Turbidity/pressure fluctuations |

Plunger performs better |

|

Cost & OPEX |

Investment, energy, spare parts |

Centrifugal more cost-effective |

|

Noise & vibration limits |

Industrial compliance |

Centrifugal preferable |

Tips for Pump Configuration in RO Engineering

To maximize performance and lifespan:

|

Design Item |

Recommendation |

|

Material selection |

316L SS or Duplex SS for corrosion protection |

|

Energy efficiency |

Select pump to operate near Best Efficiency Point (BEP) |

|

Pressure stability |

VFD + pressure control loop |

|

Membrane protection |

Avoid rapid start-stop and pressure shock |

|

Pretreatment alignment |

Maintain SDI < 5 to reduce scaling on pump and RO stage |

Proper matching of pump, membrane, and pretreatment = lower fouling + lower cost + longer service life ✅

Conclusion

Choosing the right high-pressure pump is essential to RO performance. In general:

Centrifugal Pumps = Large flow, stable, cost-effective → Best for BWRO

Plunger Pumps = Ultra-high pressure, precise control → Best for SWRO

By evaluating pressure, salinity, water variability, and project economics, engineers can design pump configurations that ensure energy-efficient and reliable RO system operation.

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo