How to Quickly Determine If a Seawater RO Membrane Has Suffered Severe Scaling or Fouling| Insights by AQUALITEK

LLearn the fastest and most effective methods to diagnose severe scaling or fouling in seawater RO membranes, including key symptoms, performance indicators, inspection techniques, and preventive strategies.

- Introduction

- 1. Understanding Membrane Scaling vs Fouling

- 1.1 What Is Scaling?

- 1.2 What Is Fouling?

- 2. Key Early Warning Signs of Severe Scaling or Fouling

- 2.1 Rapid Increase in Differential Pressure (ΔP)

- 2.2 Significant Decline in Normalized Permeate Flow

- 2.3 Increase in Salt Passage (Lower Rejection)

- 2.4 Sudden Rise in Operating Pressure

- 3. Fast Field Diagnostic Methods (No Lab Required)

- 3.1 Pressure Profile Analysis

- 3.2 SDI & Turbidity Trend Review

- 3.3 Normalization Software or Excel Tracking

- 4. Quick Shutdown Inspection Methods

- 4.1 Visual Autopsy of Removed Membrane Element

- 4.2 Simple Acid Solubility Test (Field Method)

- 5. Distinguishing Scaling vs Fouling: Rapid Decision Table

- 6. CIP Cleaning Response Test (Most Reliable Confirmation)

- 6.1 Acid Cleaning Test

- 6.2 Alkaline + Biocide Cleaning Test

- 7. Advanced Diagnostic Tools (For Large Plants)

- 8. Preventive Strategies to Avoid Severe Scaling & Fouling

- 8.1 Optimize Pretreatment Design

- 8.2 Optimize Chemical Dosing

- 8.3 Proper System Design

- 9. Real Industry Case

- Conclusion

Introduction

Seawater reverse osmosis (SWRO) systems operate under extremely harsh conditions: high salinity, high operating pressure, and complex marine contaminants. Over time, RO membranes are prone to scaling, biofouling, colloidal fouling, and organic contamination, which can severely degrade system performance.

If membrane fouling or scaling is not detected early, it can lead to:

•Rapid flux decline

•Sharp pressure increase

•Poor salt rejection

•Higher energy consumption

•Irreversible membrane damage

Therefore, quickly and accurately determining whether a seawater RO membrane has suffered severe scaling or fouling is critical for plant reliability and operational cost control.

This article provides a comprehensive, step-by-step diagnostic guide to help operators rapidly identify membrane health issues.

1. Understanding Membrane Scaling vs Fouling

1.1 What Is Scaling?

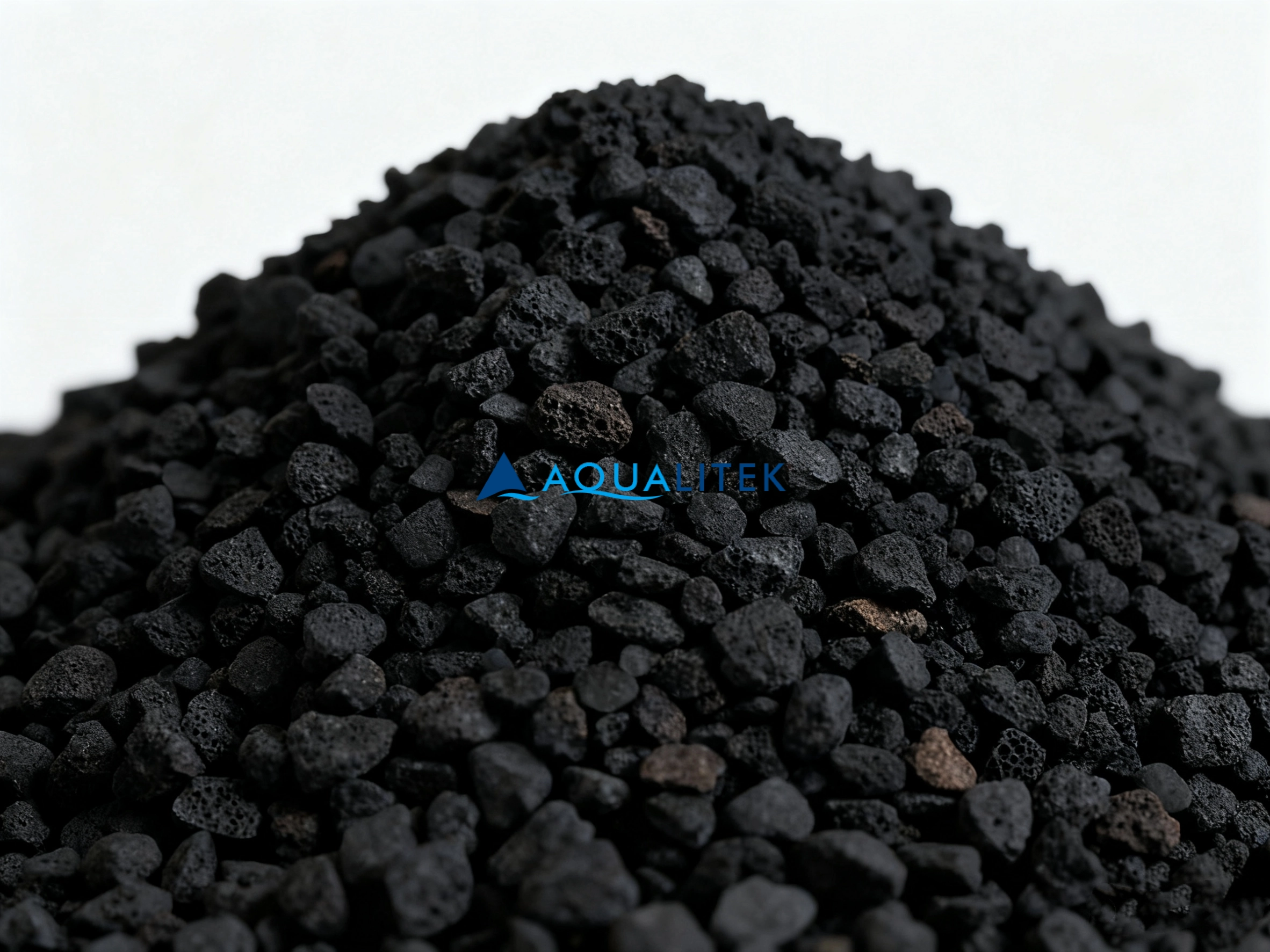

Scaling occurs when sparingly soluble salts precipitate and deposit on the membrane surface, such as:

•Calcium carbonate (CaCO₃)

•Calcium sulfate (CaSO₄)

•Barium sulfate (BaSO₄)

•Strontium sulfate (SrSO₄)

•Silica

Main causes: high recovery, high temperature, insufficient antiscalant dosing, pH imbalance.

1.2 What Is Fouling?

Fouling refers to the accumulation of suspended solids, organic matter, microorganisms, and colloids, including:

•Biofouling

•Organic fouling

•Colloidal fouling

•Particulate fouling

Main causes: poor pretreatment, high SDI, algae blooms, oil contamination, iron leakage.

2. Key Early Warning Signs of Severe Scaling or Fouling

2.1 Rapid Increase in Differential Pressure (ΔP)

The most sensitive indicator.

•Normal ΔP increase: < 10–15%

•Warning level: > 20–25%

•Severe fouling: > 30–40%

If pressure drop across membrane stages rises sharply, fouling is almost certainly occurring.

2.2 Significant Decline in Normalized Permeate Flow

Normalized flow accounts for temperature and pressure effects.

|

Decline Range |

Condition Assessment |

|

5–10% |

Mild fouling |

|

10–15% |

Moderate fouling |

|

>15–20% |

Severe fouling |

A drop of more than 15% usually indicates serious membrane contamination.

2.3 Increase in Salt Passage (Lower Rejection)

•Salt rejection decreases

•Product water conductivity increases

This suggests organic fouling, biofouling, or membrane surface blockage.

2.4 Sudden Rise in Operating Pressure

If feed pressure increases >10–15% to maintain the same flow, fouling or scaling is very likely.

3. Fast Field Diagnostic Methods (No Lab Required)

3.1 Pressure Profile Analysis

Compare pressure readings:

•Feed pressure

•Inter-stage pressure

•Concentrate pressure

Typical diagnosis patterns:

|

Symptom |

Likely Cause |

|

Front-stage ΔP rise |

Particulate fouling |

|

Uniform ΔP rise |

Organic fouling |

|

Last-stage ΔP rise |

Scaling |

3.2 SDI & Turbidity Trend Review

Check pretreatment performance:

•SDI > 3

•Turbidity > 1 NTU

→ High risk of fouling.

3.3 Normalization Software or Excel Tracking

Use normalized parameters:

•Normalized permeate flow

•Normalized pressure drop

•Normalized salt rejection

This removes seasonal effects and provides accurate fouling diagnosis.

4. Quick Shutdown Inspection Methods

If severe fouling is suspected:

4.1 Visual Autopsy of Removed Membrane Element

Look for:

•White or crystalline deposits → Scaling

•Brown slime → Biofouling

•Black greasy film → Organic fouling

•Red/brown rust → Iron fouling

4.2 Simple Acid Solubility Test (Field Method)

•Take surface deposit

•Add diluted HCl

Bubbles → carbonate scaling

No reaction → silica or biofouling

5. Distinguishing Scaling vs Fouling: Rapid Decision Table

|

Indicator |

Scaling |

Fouling |

|

ΔP increase |

Moderate |

High |

|

Flow decline |

Moderate |

High |

|

Salt passage |

Slight |

High |

|

Visual |

White crystals |

Slime, dark film |

|

CIP response |

Acid effective |

Alkaline + biocide |

6. CIP Cleaning Response Test (Most Reliable Confirmation)

6.1 Acid Cleaning Test

If acid CIP restores >80% flux, problem was inorganic scaling.

6.2 Alkaline + Biocide Cleaning Test

If alkaline cleaning restores >80% flux, fouling was organic or biological.

7. Advanced Diagnostic Tools (For Large Plants)

•Membrane fouling monitors (MFM)

•Online SDI analyzers

•Particle counters

•Biofouling activity monitors

•Autopsy lab analysis

These tools enable early-stage detection before severe damage occurs.

8. Preventive Strategies to Avoid Severe Scaling & Fouling

8.1 Optimize Pretreatment Design

•Dual media filtration

•Ultrafiltration (UF)

•DAF systems

8.2 Optimize Chemical Dosing

•High-performance antiscalants

•Continuous biocide shock dosing

•Iron removal pretreatment

8.3 Proper System Design

•Conservative recovery

•Uniform crossflow velocity

•Low fouling flux design

9. Real Industry Case

A 50,000 m³/day SWRO plant experienced:

•ΔP increase: 38%

•Flow decline: 22%

•Feed pressure rise: 9 bar

Diagnosis:

•Severe biofouling caused by algae bloom.

Solution:

•Emergency alkaline CIP

•Improved pretreatment coagulation

•Continuous low-dose chlorination

Result:

•95% performance recovery.

Conclusion

The fastest way to determine severe scaling or fouling in seawater RO membranes is by monitoring differential pressure, normalized flow, salt rejection, and pressure demand trends.

Early detection combined with proper CIP strategy and optimized pretreatment can:

•Prevent irreversible membrane damage

•Reduce downtime

•Minimize operating costs

•Extend membrane lifespan

Proactive diagnosis is the key to stable and efficient desalination operation.

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo