Article

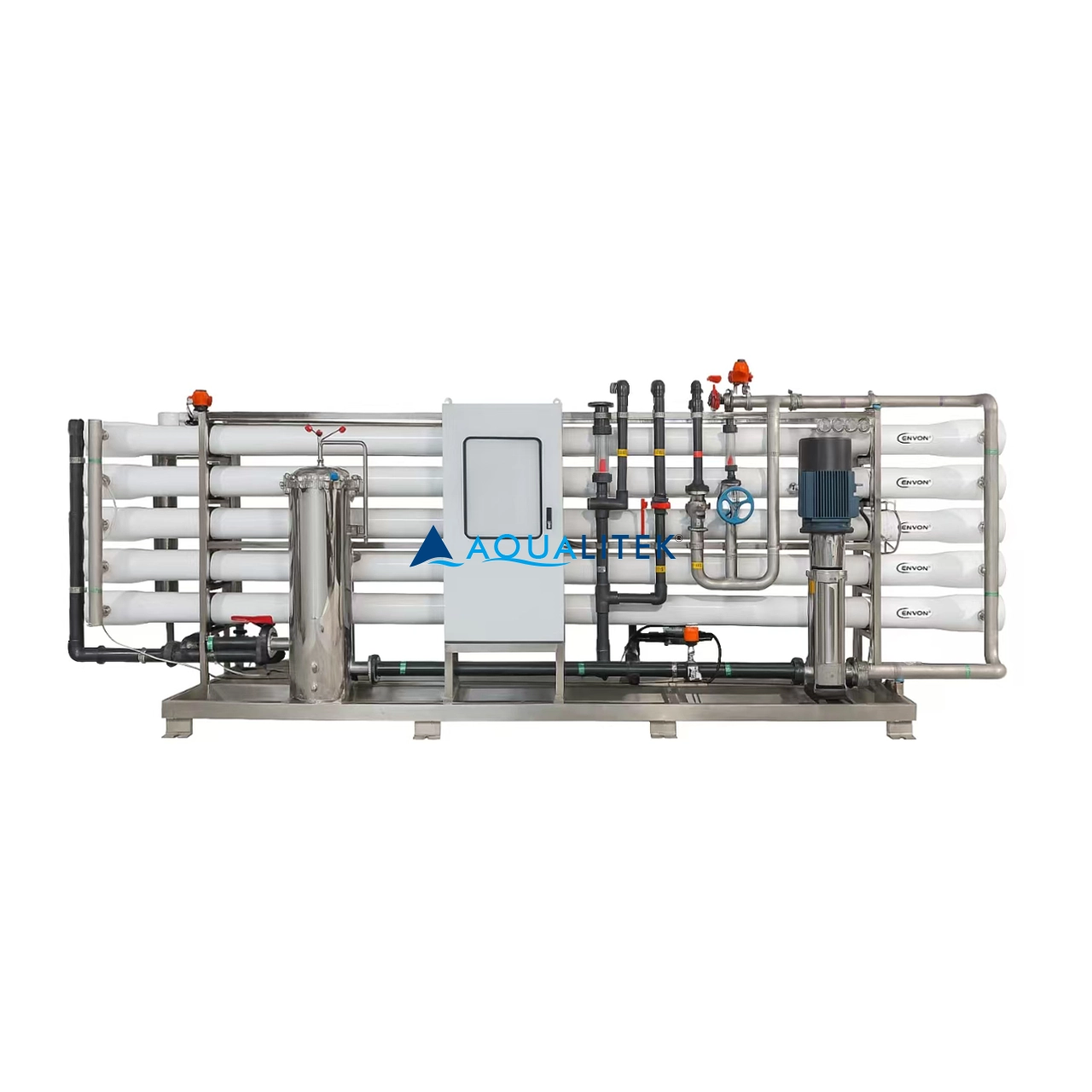

How 4TPH RO Systems Improve Plant Water Quality

Why Choose a 4TPH Industrial Reverse Osmosis System?

Buyer's Guide to Industrial Reverse Osmosis Systems

Scaling and Expansion: Integrating a 30TPH Industrial RO System

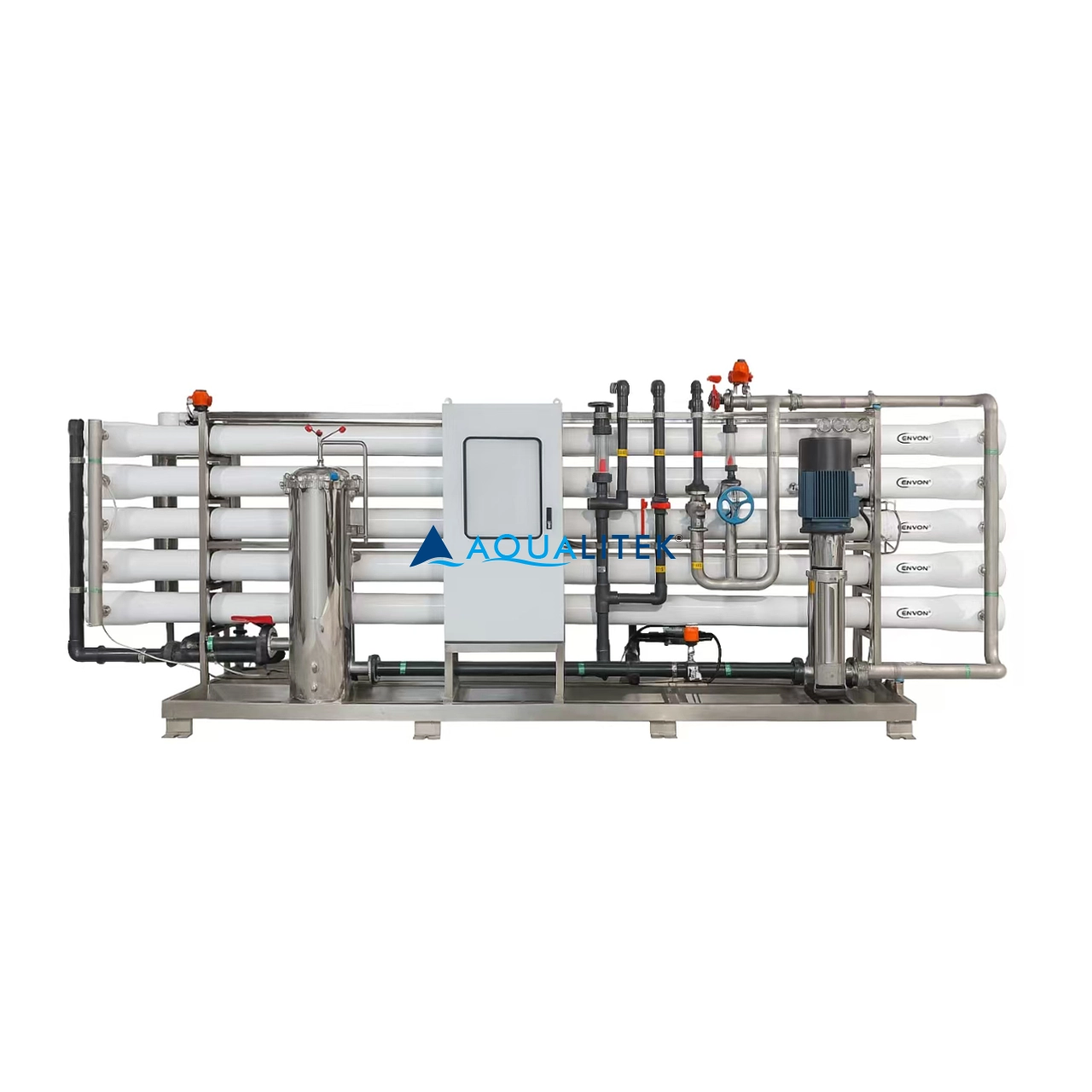

Pre-treatment Requirements for Commercial Reverse Osmosis Systems

Pre-treatment is critical for any commercial reverse osmosis system to ensure membrane lifespan, consistent permeate quality, and energy-efficient operation. This article explains the essential feedwater conditioning steps, monitoring targets, and best practices for protecting a 30TPH Industrial Reverse Osmosis (RO) System in industrial and municipal applications.

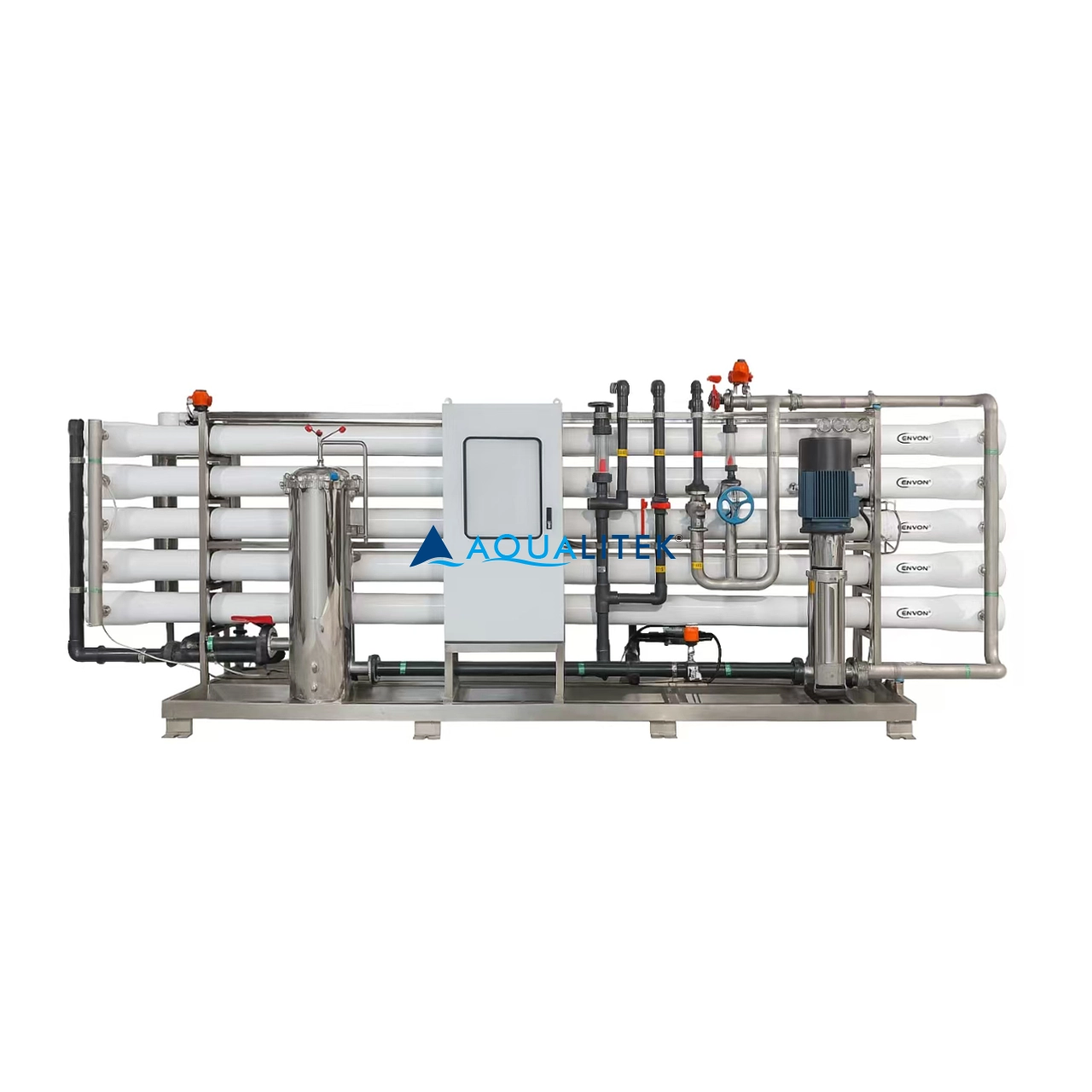

Operational Costs and ROI of Commercial Reverse Osmosis Systems

Comparing Commercial Reverse Osmosis Systems by Performance

Maintenance Checklist for a 30TPH Industrial Reverse Osmosis System

Energy Efficiency Tips for Commercial Reverse Osmosis Systems

Selecting the Right Commercial RO System for High-Capacity Needs

How Commercial Reverse Osmosis Systems Improve Water Quality

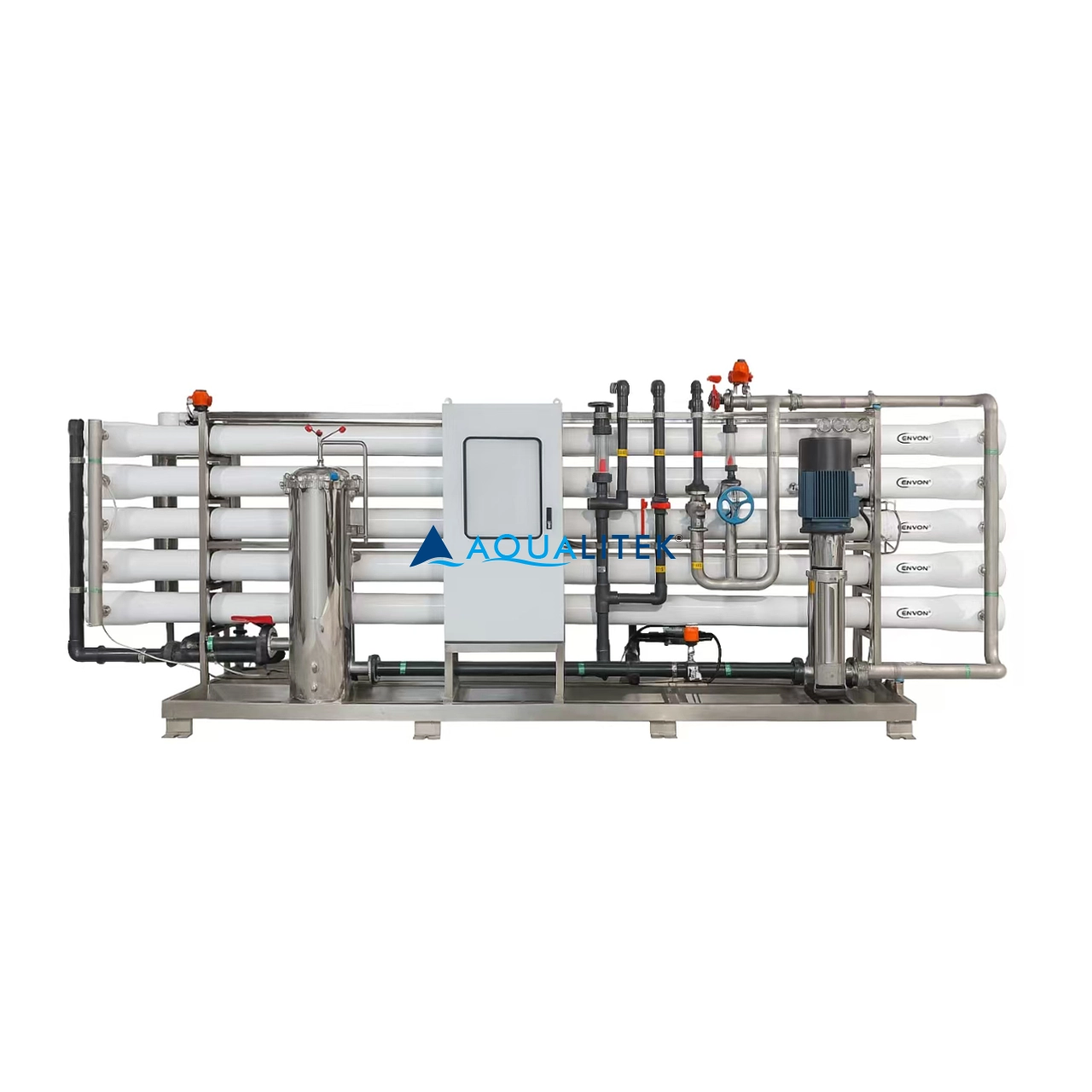

Why Choose a 30TPH Industrial Reverse Osmosis (RO) System

Buying Guide: Commercial Reverse Osmosis System Essentials

Selecting Electrodeionization Systems for Semiconductor and Lab Use

Troubleshooting Common Electrodeionization Performance Issues

Operating Best Practices for Electrodeionization Systems

Validating Electrodeionization Systems for Pharmaceutical Water

Maintenance and Lifecycle Considerations for Electrodeionization

Integration Tips for Electrodeionization in Water Treatment Plants

How Electrodeionization Systems Improve Water Purity Reliability

Benefits of Electrodeionization for Continuous Ultrapure Water

Choosing Electrodeionization Systems: Key Specs to Compare

Buyer’s Guide: Electrodeionization Systems for Ultrapure Water

Scalability and Modular Design of Industrial RO Systems

What Is the Typical Design Recovery Rate for a Single-Stage Seawater RO System?| Insights by AQUALITEK

Where Are Scale Inhibitors and Reducing Agents Typically Added in RO Systems?| Insights by AQUALITEK

What Is the Core Role of a Security Filter (Precision Filter) in Desalination Pretreatment?| Insights by AQUALITEK

Which Online Monitoring Instrument in a Seawater RO System Requires the Most Accurate and Frequent Calibration?| Insights by AQUALITEK

What Sudden Unusual Noises from High-Pressure Pumps and Energy Recovery Devices Indicate During Routine Inspections| Insights by AQUALITEK

Request More Information

Reach out to us and get fast, accurate, and personalized product details to support your next project.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo