Choosing Electrodeionization Systems: Key Specs to Compare

- Key Performance Indicators for Ultra-Pure Water Systems

- Product Water Purity: Resistivity and Conductivity

- Flow Rate: Capacity vs. Consistency

- Recovery Rate and Water Savings

- Feedwater Requirements and Pre-treatment

- Feed Conductivity/TDS and Hardness Limits

- Organic and Silica Control

- Temperature and pH Sensitivity

- Design and Operational Specifications

- Electrical Consumption and Power Requirements

- Module Life, Maintenance, and Consumables

- Control, Monitoring, and Automation

- Selecting Vendor and Lifecycle Considerations

- Performance Guarantees and Validation Support

- Service Network and Spare Parts Availability

- Total Cost of Ownership (TCO)

- Comparative Specs Table: How to Read Vendor Data

- Product Spotlight: Electrodeionization Systems to Get UltraPure Water

- Brand advantages and why this product fits your needs

- Case uses and typical industries

- Installation, Operations, and Troubleshooting

- Site Preparation and Commissioning

- Common Operational Issues and Fixes

- Monitoring and Alarm Strategy

- Regulatory and Environmental Considerations

- Regulatory Compliance and Documentation

- Environmental Benefits of EDI

- Frequently Asked Questions (FAQ)

- Q: What feedwater do I need before EDI?

- Q: Can EDI replace mixed-bed deionizers?

- Q: How long do EDI modules last?

- Q: How do I size an EDI system?

- Q: Is chemical free always better?

- Next Steps — Contact and Product Information

Electrodeionization (electrodeionization, EDI) combines ion-exchange resins and ion-exchange membranes with an applied electric field to produce continuous ultrapure water without chemical regeneration. For facilities seeking consistent high resistivity (low conductivity) water with low operating chemical impact, comparing key specs such as product water resistivity, flow capacity, recovery, feedwater quality requirements, power consumption, and footprint is essential to choose the right EDI system for your application. Once these specifications are clearly defined, it becomes easier to understand the broader benefits of electrodeionization for continuous ultrapure water production compared with conventional polishing technologies.

Key Performance Indicators for Ultra-Pure Water Systems

Product Water Purity: Resistivity and Conductivity

When evaluating electrodeionization systems, the most important metric is the required product water purity. Purity is commonly expressed as resistivity (Megohm-cm at 25°C) or conductivity (µS/cm). Typical EDI systems deliver water in the range of 0.05–1.0 µS/cm (≈18.2–0.055 MΩ·cm), depending on feed quality and design. Semiconductor and pharmaceutical processes often require 18.2 MΩ·cm. Ensure vendors provide guaranteed outlet resistivity under specified feed conditions and temperature.

Flow Rate: Capacity vs. Consistency

Match the EDI module flow capacity to peak and average demand. Manufacturers rate modules in L/h or m3/hr at specified resistivity or conductivity setpoints. It's better to size for peak demand with some margin rather than continuous maxing out modules, because high flow can reduce contact time and lower outlet purity. Consider modular systems that allow staged scaling as demand grows.

Recovery Rate and Water Savings

Recovery rate (percentage of feedwater converted into product water) is a critical operational cost variable. EDI systems typically offer high recovery compared with mixed-bed chemistry-based systems because they minimize chemical regeneration losses. Typical recoveries range from 85% to >95% with good pretreatment. Higher recovery reduces wastewater and operating costs but may increase risk of breakthrough if feed TDS spikes—so monitor feedwater closely.

Feedwater Requirements and Pre-treatment

Feed Conductivity/TDS and Hardness Limits

Electrodeionization is most effective after reverse osmosis (RO) polishing. Most EDI vendors specify a maximum feed conductivity (or TDS) and hardness level. Typical requirements: RO permeate conductivity below 20–50 µS/cm and hardness <0.1–0.2 mg/L as CaCO3 to prevent scaling and fouling. If feedwater exceeds those limits, additional pretreatment (e.g., softening, antiscalant dosing, or improved RO staging) is required.

Organic and Silica Control

Organic matter and silica can foul ion exchange resins and membranes, reducing EDI efficiency. Many systems need dissolved organic carbon (DOC) and silica below defined thresholds. For silica, limits often are <1–2 mg/L (as reactive silica), and organics should be controlled by upstream RO, activated carbon, or ultrafiltration. Regular monitoring and periodic cleaning protocols help maintain long-term performance.

Temperature and pH Sensitivity

Temperature affects resistivity readings and EDI performance: higher temperatures lower resistivity numerically, so systems often include temperature compensation for accurate control. pH extremes can damage membranes and resins; typical allowable feed pH is between 6 and 9. Check vendor specifications for operating ranges and necessary safeguards.

Design and Operational Specifications

Electrical Consumption and Power Requirements

Unlike chemical deionization, EDI uses DC power to drive ion migration. Compare power consumption (kW per m3 or per module) when evaluating life-cycle costs. Power draw rises with feed conductivity and required product purity. Vendors usually provide power vs. conductivity curves—request these to estimate real operating costs under your feedwater conditions.

Module Life, Maintenance, and Consumables

EDI modules have expected lifetimes (often 5–15 years) and require periodic maintenance such as cleaning and replacement of electrodes or membranes. Although chemical regenerants are eliminated, you should factor in costs for DI polishing cartridges, occasional acid/base cleanings, and monitoring sensors. Ask for mean time between maintenance (MTBM) and recommended maintenance schedules.

Control, Monitoring, and Automation

Modern EDI systems incorporate PLC/SCADA integration, remote monitoring, and automated backflush or cleaning cycles. Look for features such as continuous resistivity monitoring, alarm thresholds, data logging for quality traceability, and automatic feed adjustments. These capabilities support compliance in regulated industries (e.g., pharma) and reduce operator labor.

Selecting Vendor and Lifecycle Considerations

Performance Guarantees and Validation Support

Choose suppliers who provide clear guarantees for product water quality under specified feed conditions and who supply validation documentation and protocols (IQ/OQ/PQ) if needed for regulated environments. Reputable sources like Water Quality Association guidance can help assess vendor claims: Water Quality Association.

Service Network and Spare Parts Availability

Local service presence, rapid spare parts availability, and trained technicians reduce downtime. Consider vendors offering service contracts, remote diagnostics, and fast shipping for membranes and electrodes. Long-term OEM support is crucial for continuous processes such as power plant boilers or semiconductor fabs.

Total Cost of Ownership (TCO)

Evaluate TCO including capital cost, energy consumption, pre-treatment requirements, maintenance, consumables, waste handling, and expected lifespan. A higher initial cost may be justified by lower operating costs and reduced chemical handling. For lifecycle planning, factor in scalability: modular EDI allows capacity expansion with minimal disruption.

Comparative Specs Table: How to Read Vendor Data

Below is a sample comparison table to help you compare candidate EDI systems. Replace the example numbers with vendor-provided values for precise evaluation.

| Specification | Typical Range | Application Impact |

|---|---|---|

| Outlet Resistivity (MΩ·cm) | 0.055–18.2 (0.05–18.2) | Defines suitability for semiconductor/pharma vs. general lab use |

| Flow Rate per Module | 0.5–20 m3/hr | Determines number of modules and footprint |

| Recovery | 85–95%+ | Lower wastewater and operating costs |

| Feed RO Permeate Conductivity | <20–50 µS/cm | Higher feed conductivity reduces performance and increases power draw |

| Power Consumption | 0.05–0.5 kWh/m3 (varies) | Major contributor to operating cost |

| Module Lifetime | 5–15 years | Impacts replacement budget and TCO |

Product Spotlight: Electrodeionization Systems to Get UltraPure Water

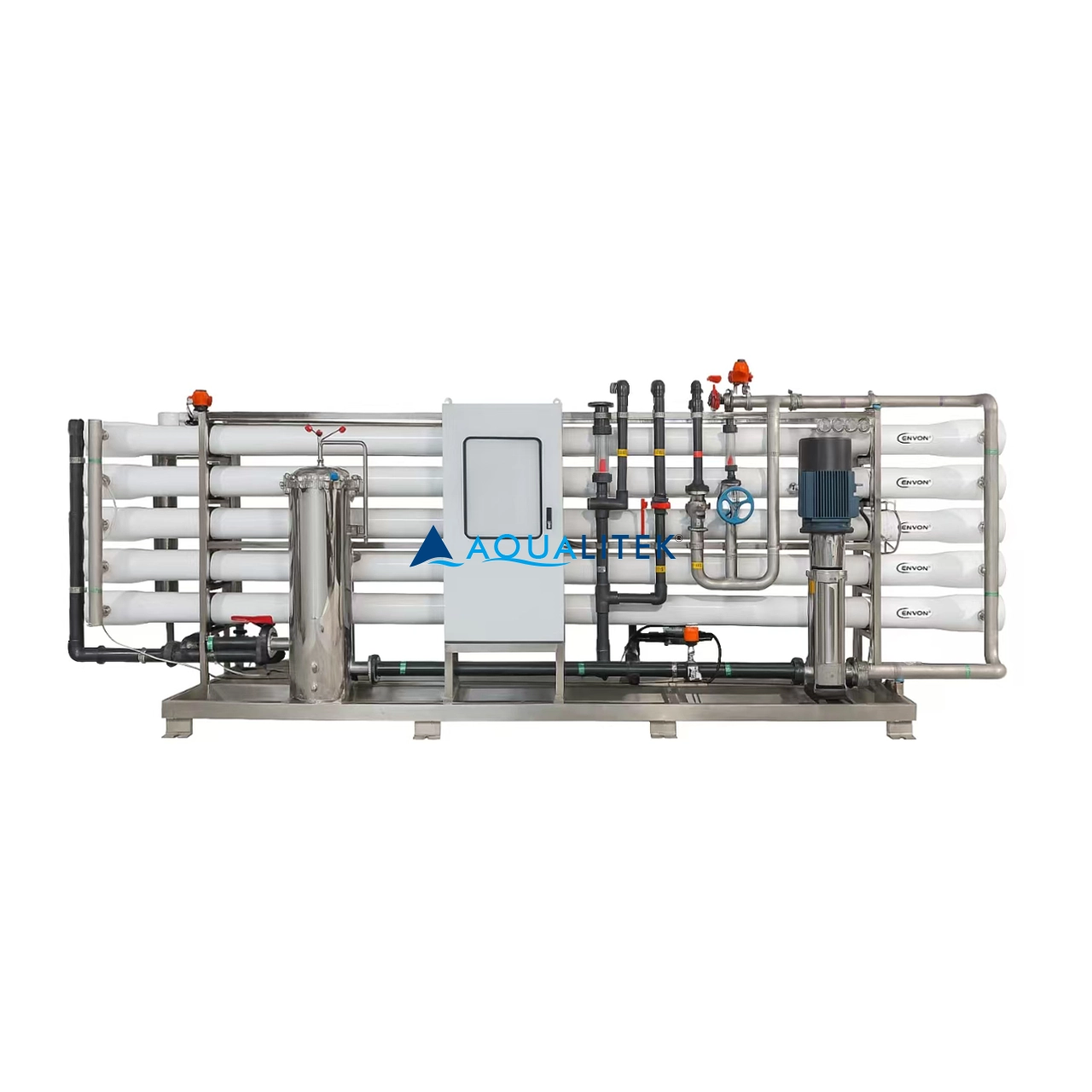

Product overview:

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

Brand advantages and why this product fits your needs

When selecting an EDI system branded as Electrodeionization Systems to Get UltraPure Water, consider these typical advantages we design into our solutions:

- Guaranteed outlet resistivity and validated performance documentation for regulated industries.

- High recovery design to minimize wastewater and reduce utilities cost.

- Modular architecture for easy capacity scaling and redundancy.

- Integrated PLC/SCADA monitoring and remote diagnostics to reduce downtime.

- Low lifecycle environmental footprint—no chemical regenerants and reduced hazardous waste.

Case uses and typical industries

Electrodeionization is widely adopted where continuous ultrapure water is required: semiconductor rinse lines, pharmaceutical API production, high-pressure boiler feedwater polishing in power plants, laboratory-grade water for analytical instruments, and biotech fermentation media preparation. For a primer on electrodeionization technology, see the overview on Wikipedia.

Installation, Operations, and Troubleshooting

Site Preparation and Commissioning

Plan piping, electrical supply (DC power rectifier), ventilation, and space for module replacement. Commissioning should include verification of feedwater quality, verification of instrument calibration (resistivity/conductivity), and performance testing across expected load profiles. Request vendor-led IQ/OQ/PQ services if your operation requires formal validation.

Common Operational Issues and Fixes

Common problems include reduced outlet resistivity, increased pressure drop, and membrane fouling.

- Reduced resistivity: Check feedwater conductivity spikes, temperature compensation, and verify DC power levels. Consider staged RO improvements or polishing cartridges.

- Increased pressure drop: Inspect for scale or particulate fouling; review pre-filtration (e.g., 5 µm or 1 µm cartridge filters) and maintenance schedule.

- Membrane or resin degradation: Follow vendor cleaning protocols and replace membranes when performance cannot be restored.

Monitoring and Alarm Strategy

Implement real-time resistivity/conductivity monitoring at the outlet and key process points. Configure alarms for feed conductivity excursions, low product resistivity, power anomalies, and maintenance thresholds. Automated logging supports trend analysis and preventive maintenance.

Regulatory and Environmental Considerations

Regulatory Compliance and Documentation

In pharmaceutical and biotech industries, water systems must comply with pharmacopeial standards (e.g., USP/EP) and require thorough documentation. Ensure EDI vendors provide documentation aligned with Good Manufacturing Practices (GMP). For environmental best practices and industry guidance, consult resources such as the Water Quality Association: https://www.wqa.org/.

Environmental Benefits of EDI

EDI systems reduce chemical usage and hazardous waste generation compared with conventional mixed-bed deionizers. High recovery rates further reduce freshwater consumption and wastewater. When evaluating environmental impact, include electricity source (grid carbon intensity) and potential energy-efficiency measures.

Frequently Asked Questions (FAQ)

Q: What feedwater do I need before EDI?

A: EDI performs best downstream of a reverse osmosis (RO) system. Typical RO permeate conductivity should be <20–50 µS/cm and hardness <0.1–0.2 mg/L as CaCO3. Additional pretreatment (carbon filtration, antiscalant, softening) may be required based on raw water quality.

Q: Can EDI replace mixed-bed deionizers?

A: In many continuous-process applications, yes. EDI provides continuous deionization without chemical regeneration, lowering operating labor and hazardous waste. However, for intermittent or very low-flow applications with variable feed quality, mixed beds might still be appropriate. Evaluate on a case-by-case basis.

Q: How long do EDI modules last?

A: Typical module life ranges from 5 to 15 years depending on feedwater quality, maintenance, and operating conditions. Proper pretreatment and preventative maintenance can extend service life.

Q: How do I size an EDI system?

A: Base sizing on peak flow demand at required product resistivity plus a contingency margin (often 10–25%). Confirm sizing with vendor-provided performance curves that show flow vs. outlet resistivity under your specific feed conditions.

Q: Is chemical free always better?

A: Eliminating chemical regenerants reduces hazardous waste and operator exposure, but EDI still requires cleaning/regeneration steps occasionally and proper pretreatment. Consider full lifecycle costs and environmental factors when deciding.

Next Steps — Contact and Product Information

If you are ready to evaluate electrodeionization systems for your facility, our Electrodeionization Systems to Get UltraPure Water product line offers modular solutions, validated performance, and global service support. Contact our technical sales team for a feedwater assessment, site survey, and customized proposal.

Contact Customer Service | View Product Details

References: Technical overview of EDI on Wikipedia and industry guidance from the Water Quality Association.

Why Choose a 30TPH Industrial Reverse Osmosis (RO) System

Water Purification System Installation: Step-by-Step Guide

Water Purification System Certifications to Trust

Scaling Water Treatment: When to Upgrade to a 12TPH UF Device

Solutions

Are AQT’s water treatment products certified?

Yes! Our products comply with international quality and safety standards, including ISO, CE, and NSF certifications. We prioritize high-quality materials, advanced technology, and strict quality control to ensure superior performance and reliability.

Ion Exchange Water Treatment Systems

Which chemicals are required for regeneration?

Softening uses NaCl. Demineralization uses HCl or H₂SO₄ for cation resin and NaOH for anion resin.

Water Filters

Can I automate the filter cleaning process?

Absolutely. Our automatic backwash filters come with timer-based or differential pressure-triggered controls.

Blog

Do softener systems remove iron or chlorine?

Not typically. If your water contains iron, manganese, or chlorine, consider a dual-system setup or add specialized pre-filters.

Membrane Water Treatment Systems

Do you offer plug-and-play solutions?

Absolutely. We offer containerized membrane systems that are factory-tested, compact, and quick to deploy.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWE Series

TWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for tap water (lower TDS). The large volumes can help meet your a variety of industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo