Scalability and Modular Design of Industrial RO Systems

- Design Principles for Modern Industrial Water Treatment

- What scalability really means

- Modular vs. monolithic system approaches

- Key performance indicators to design for

- Modular Architecture of Industrial RO Systems

- Skid-mounted modules and plug-and-play expansion

- Parallel and staged configurations

- Pretreatment and post-treatment integration

- Scaling Strategies, Operation and Maintenance

- Phased capacity growth and investment planning

- Cleaning, fouling control and lifecycle management

- Energy efficiency and recovery considerations

- Case Study: AQUALITEK 4TPH Industrial Reverse Osmosis

- Product overview

- Technical highlights and modular benefits

- Performance comparison

- Operational Best Practices and Compliance

- Monitoring and automation

- Regulatory and quality standards

- Space, piping and electrical planning

- Brand Advantages and Why Choose AQUALITEK

- Proven modular engineering

- Support, service and lifecycle planning

- Application focus and customization

- FAQ — Scalability and Modular RO Systems

- Q: What is the main benefit of a modular industrial ro system?

- Q: How easy is it to add capacity with the AQUALITEK 4TPH system?

- Q: What pretreatment is required for long membrane life?

- Q: How does modular design affect operational energy use?

- Q: Is the AQUALITEK 4TPH suitable for electronic component cleaning water?

Scalability and modular design are foundational for reliable industrial water treatment. Industrial facilities need consistent permeate quality, predictable throughput, and the ability to grow or reconfigure without major downtime. A modern reverse osmosis-based industrial ro system integrates robust pretreatment, membrane modules, energy recovery where applicable, and simple mechanical interfaces that let operators add or remove capacity quickly while maintaining TDS reduction, SDI control and permeate quality suitable for manufacturing applications. As production demands evolve, modular expansion often triggers a return to the industrial RO system selection guide for procurement managers to reassess capacity and configuration.

Design Principles for Modern Industrial Water Treatment

What scalability really means

Scalability in an industrial ro system refers to the ability to increase (or sometimes decrease) treated water production with minimal redesign. This includes adding parallel membrane trains, stacking skid modules, or upgrading pumps and membranes. Key semantic concepts tied to scalability include flow capacity, permeate flow rate, TDS reduction, modular skid-mounted components, and brine management. Scalable solutions reduce capital risk by allowing staged investment aligned with production growth.

Modular vs. monolithic system approaches

Monolithic RO plants are custom-built, large single installations. Modular systems consist of standardized, skid-mounted RO units and support skids (pretreatment, chemical dosing, CIP). Modularity improves interchangeability, reduces commissioning time, and simplifies spare parts inventory. For many manufacturers, a modular industrial RO system offers higher uptime because faulty modules can be isolated and serviced offline while the rest continue operating.

Key performance indicators to design for

When evaluating designs, prioritize metrics that predict long-term success: recovery rate (brine recovery), specific energy consumption (kWh/m3), permeate conductivity or TDS, salt rejection, SDI (silt density index), and membrane flux. These indicators determine whether a system meets process water specifications (for example, electronic component cleaning) and how easily it scales. Monitoring systems and data logging are essential to preserve these KPIs as capacity changes.

Modular Architecture of Industrial RO Systems

Skid-mounted modules and plug-and-play expansion

Skid-mounted RO modules typically include high-pressure pumps, membrane housings, a control panel, and basic instrumentation. Their plug-and-play nature makes it straightforward to add identical modules in parallel to increase capacity. This modular architecture supports consistent performance across units because each module operates under identical hydraulic and control logic. For example, deploying multiple AQUALITEK 4TPH modules allows a plant to scale output in 4 m3/hr increments while keeping control complexity low.

Parallel and staged configurations

Parallel configurations increase peak capacity by running modules simultaneously; staged (series) configurations improve recovery and salt rejection for difficult feedwaters. Choosing between parallel vs staged depends on feedwater TDS, hardness, and pretreatment quality. Semantic terms relevant here include membrane filtration staging, permeate blending, and recovery optimization. A modular system can be designed to support both strategies—parallel for raw capacity and staged trains for high-recovery or high-salinity situations.

Pretreatment and post-treatment integration

RO membranes are sensitive to fouling, scaling, and biological growth. Effective modular plants integrate pretreatment skids—media filters, cartridge filtration, antiscalant dosing, water softening, and UV/disinfection if required. Post-treatment may include remineralization, pH adjustment, and polishing filters to meet required conductivity or resistivity for specific uses like electronic component cleaning. Integration ensures each module receives consistent feedwater quality, which is critical for long membrane life and predictable scale-up.

Scaling Strategies, Operation and Maintenance

Phased capacity growth and investment planning

Phased growth reduces upfront capital expenditure and aligns investment with real production demand. A common approach is to install a baseline modular system that meets current needs and reserve space and connections for future modules. This strategy minimizes process interruptions: new modules can be pre-tested offline and then brought online during low-demand periods. Important semantic keywords: capacity ramp-up, phased commissioning, and modular expansion lanes.

Cleaning, fouling control and lifecycle management

Maintenance strategies such as scheduled CIP (clean-in-place), inline backwash, and targeted membrane replacement extend operational life and preserve system scalability. Monitoring SDI and turbidity upstream helps prevent fouling. Modular systems improve lifecycle management because individual skids can be taken offline for service without shutting down entire production. Documented maintenance protocols and spare module strategies are best practice for continuous operations.

Energy efficiency and recovery considerations

Energy is a major operational cost for RO plants. For high-volume plants, consider energy recovery devices and high-efficiency pumps. Modular systems allow selecting optimized pumps and controls per module, which can reduce specific energy consumption (kWh/m3) across a range of loads. Semantic terms: energy recovery device (ERD), variable frequency drive (VFD), specific energy consumption, and optimization at partial loads.

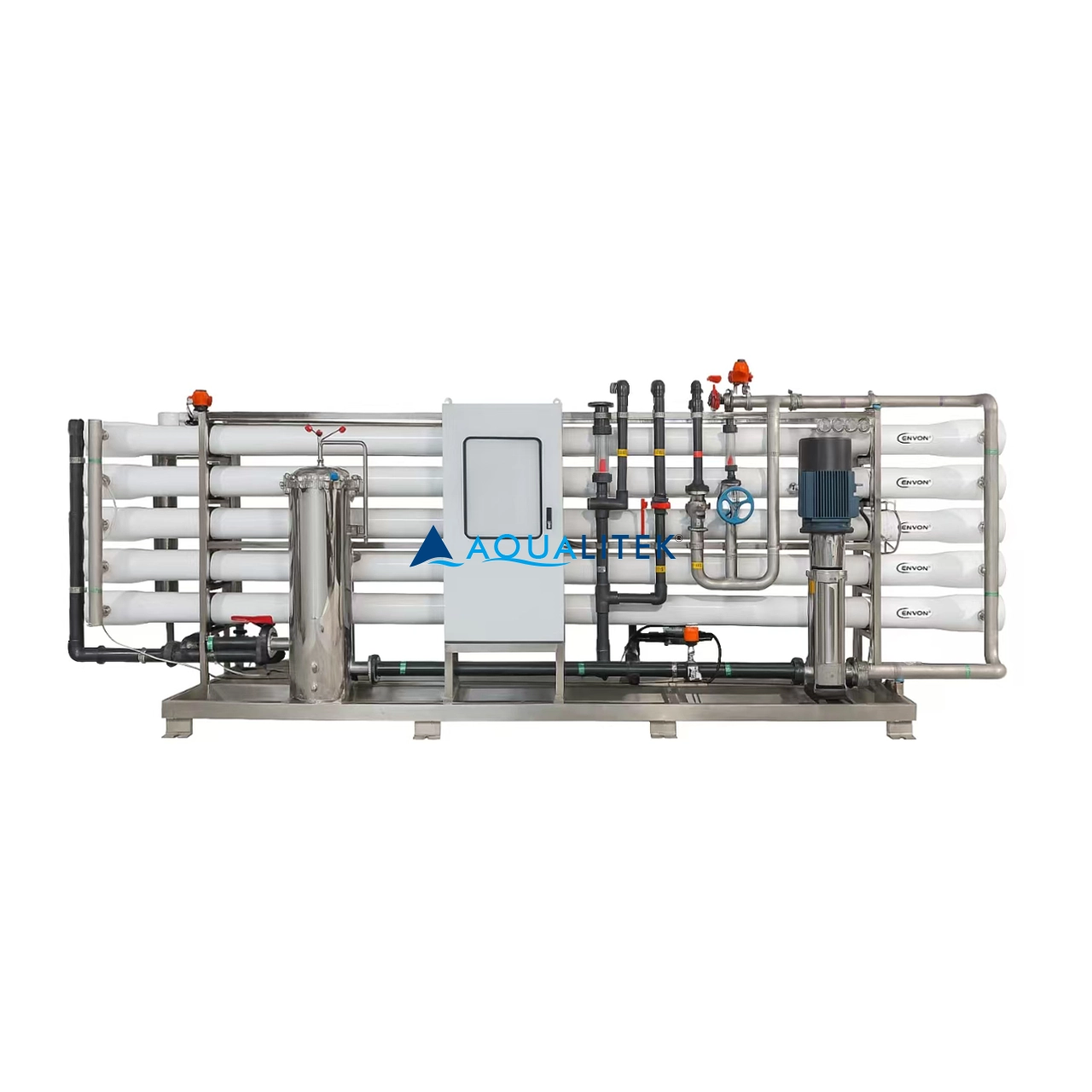

Case Study: AQUALITEK 4TPH Industrial Reverse Osmosis

Product overview

AQUALITEK 4TPH Industrial Reverse Osmosis Water Purification RO System is a high-efficiency industrial-grade RO water treatment plant for manufacturing & processing, a commercial reverse osmosis filtration system ideal for electronic component cleaning water use.

Technical highlights and modular benefits

The 4TPH unit provides approximately 4 tons per hour (roughly 4 m3/hr) of permeate under typical feed and recovery conditions. As a skid-mounted, modular industrial ro system, it offers the following advantages: standardized mechanical and electrical interfaces for easy replication; compact footprint for retrofit projects; integrated controls for remote monitoring; and a design tuned for high permeate quality suitable for sensitive processes. Semantic keywords integrated here include membrane flux, permeate quality, brine disposal strategies, and skid-mounted RO modules.

Performance comparison

Below is a concise comparison showing trade-offs between installing one large monolithic RO plant vs multiple modular 4TPH units.

| Feature | Single Monolithic Plant | Modular 4TPH Units (e.g., AQUALITEK) |

|---|---|---|

| Scalability | Requires major retrofit to expand | Add modules in parallel; incremental capacity |

| Commissioning time | Longer, custom build | Faster; pre-tested skids |

| Downtime impact | High—maintenance affects whole plant | Low—service one module while others run |

| CapEx predictability | High initial capex; less flexible | Staged capex aligned with demand |

| Operational efficiency | Optimized at design point | Efficient across varied loads with VFDs |

For manufacturers in electronics cleaning, where permeate resistivity and particle control are critical, modular RO units like the AQUALITEK 4TPH simplify meeting precise water specs while supporting plant growth.

Operational Best Practices and Compliance

Monitoring and automation

Implement PLC or DCS integration and cloud-enabled telemetry to monitor TDS, conductivity, pressure differentials, and SDI in real time. Automated alarms and trending allow proactive maintenance and ensure each module operates within target parameters. Semantic phrases: real-time telemetry, predictive maintenance, automated CIP scheduling.

Regulatory and quality standards

Design to meet local discharge and reuse regulations. For example, ensure brine handling meets municipal and industrial effluent standards. When specifying permeate for critical processes, reference industry standards for water quality. Authoritative sources such as the water treatment overview and resources from the U.S. EPA can guide regulatory compliance and best practices.

Space, piping and electrical planning

Reserve modular lanes and make connections accessible: provide valve manifolds for isolated bypass, separate service access for pumps and membranes, and sufficient spare power capacity for future modules. Early planning for mechanical and electrical expansion reduces installation time and cost when scaling.

Brand Advantages and Why Choose AQUALITEK

Proven modular engineering

AQUALITEK’s modular 4TPH solution is engineered for repeatable performance and minimal installation complexity. Standardized skid design simplifies commissioning and spares management. This brand approach reduces technical risk and shortens project timelines for industrial clients.

Support, service and lifecycle planning

AQUALITEK offers comprehensive service options including start-up assistance, operator training, spare module strategies, and preventive maintenance contracts. This ensures predictable membrane life, reliable permeate quality, and smooth scale-up as production needs increase.

Application focus and customization

While standardized, AQUALITEK systems are configurable for feedwater variations and special requirements such as ultra-low conductivity for electronics cleaning or higher recovery for limited water sources. Their approach balances off-the-shelf reliability with tailored performance tuning.

FAQ — Scalability and Modular RO Systems

Q: What is the main benefit of a modular industrial ro system?

A: Modularity provides staged capital deployment, faster commissioning, lower downtime during maintenance, and simplified spare parts and servicing. It aligns well with uncertain or growing production demands.

Q: How easy is it to add capacity with the AQUALITEK 4TPH system?

A: Very easy. The 4TPH unit is skid-mounted and designed to be added in parallel. Additional units can be piped into a common manifold and integrated via control logic for seamless capacity expansion.

Q: What pretreatment is required for long membrane life?

A: Typical pretreatment includes multimedia filtration, cartridge filtration (5 micron or better), antiscalant dosing, and softening or antiscalant strategies for hard waters. Monitoring SDI and turbidity is essential to avoid premature fouling.

Q: How does modular design affect operational energy use?

A: Modular systems with VFDs and appropriately sized pumps can operate efficiently across partial-load conditions. Energy recovery devices are more common in larger installations but can be applied at module level where economically justified.

Q: Is the AQUALITEK 4TPH suitable for electronic component cleaning water?

A: Yes. The 4TPH is specifically noted as ideal for electronic component cleaning water because it delivers consistent permeate quality and can be configured with post-treatment polishing to meet conductivity and particle specifications required by electronics manufacturing.

For more technical details, specifications, or to request a quote, please contact our sales team or view the AQUALITEK 4TPH product page. Our experts will assist with site evaluation, flow calculations, and a modular expansion plan tailored to your process.

References and further reading: Read more about reverse osmosis on Wikipedia and general water treatment principles on Wikipedia - Water Treatment. For regulatory guidance and best practices, consult the U.S. EPA website.

Product brief (for quick reuse):

<p>AQUALITEK 4TPH Industrial Reverse Osmosis Water Purification RO System, high-efficiency industrial-grade RO water treatment plant for manufacturing & processing, commercial reverse osmosis filtration system ideal for electronic component cleaning water use.</p>

Contact us to schedule a site survey, request performance data at your feedwater conditions, or to obtain CAD layouts for plant planning. Our team specializes in modular industrial ro system projects and will help you plan a scalable, low-risk deployment.

Installation Checklist for 500 LPH Reverse Osmosis TWV - 412

Top 10 reverse osmosis system Manufacturers and Supplier Brands

Top Mistakes When Buying a Water Purification System: Practical Buyer’s Guide

Operational Costs and ROI of Commercial Reverse Osmosis Systems

Water Filters

How do I choose between a media filter and a micron filter?

Media filters are ideal for high-volume solids removal and can be backwashed. Micron filters offer precise filtration for fine particles and are best for polishing applications.

Ion Exchange Water Treatment Systems

How often is regeneration needed?

It depends on water quality and usage. Most systems regenerate every few days to a week under normal loads.

What is the difference between softening and deionization?

Softening removes only hardness ions (Ca²⁺, Mg²⁺), while deionization removes both cations and anions to produce high-purity water.

Membrane Water Treatment Systems

Can your membrane systems treat seawater?

Yes. Our seawater RO systems are designed to handle high salinity with corrosion-resistant materials and energy recovery devices.

Solutions

What industries does AQT serve?

We provide water treatment solutions for a wide range of industries, including:

1. Industrial Manufacturing – Process water treatment, cooling water, and boiler feed.

2. Hospitality & Commercial – Hotels, restaurants, and office buildings.

3. Residential Applications – Drinking water purification and softening.

4. Healthcare & Pharmaceuticals – Ultra-pure water for laboratories and hospitals.

5. Municipal & Public Utilities – Water supply and wastewater treatment.

6. Food & Beverage Processing – Filtration for beverage p

30TPH Industrial Reverse Osmosis (RO) System

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo