Maintenance and Lifecycle Considerations for Electrodeionization

- Understanding EDI Technology and Key Maintenance Drivers

- How electrodeionization works (brief)

- Primary factors that affect EDI performance

- Typical performance targets

- Pretreatment Requirements and Their Impact on Lifecycle

- Why pretreatment matters

- Recommended pretreatment train

- Monitoring pretreatment effectiveness

- Routine Maintenance Practices for Reliable Operation

- Daily and weekly checks

- Monthly and quarterly tasks

- Cleaning-in-place (CIP) and chemical cleaning

- Lifecycle Considerations: Components, Replacement Intervals, and Costs

- Component lifetimes and indicators for replacement

- Lifecycle cost comparison

- When to refurbish vs replace

- Troubleshooting Common EDI Problems

- Declining product resistivity

- Increased pressure drop across stack

- Electrode or membrane damage indicators

- Best Practices for Long-Term Reliability and Compliance

- Implement a data-driven monitoring program

- Scheduled preventive maintenance and spare parts

- Regulatory and quality compliance

- Brand Advantages: Electrodeionization Systems to Get UltraPure Water

- Sustainability and cost-efficiency

- Design for uptime and ease of maintenance

- Support, validation and service

- Frequently Asked Questions (FAQ)

- How often should EDI stacks be replaced?

- Can EDI handle silica removal?

- What are the signs of membrane fouling vs. resin exhaustion?

- How do I minimize downtime for critical processes?

- Is EDI suitable for all ultrapure water applications?

Electrodeionization (EDI) systems produce ultrapure water continuously without chemical regeneration by combining ion-exchange and electrochemical processes. Proper maintenance, pretreatment, monitoring, and lifecycle planning are critical to maximize EDI stack life, minimize downtime, and ensure consistent 18.2 MΩ·cm-quality water for pharmaceutical, semiconductor, power generation and laboratory use. This article explains practical maintenance tasks, monitoring strategies, failure modes, lifecycle costs, and upgrade pathways to help facility engineers and water quality managers get the best performance from Electrodeionization Systems to Get UltraPure Water.

Understanding EDI Technology and Key Maintenance Drivers

How electrodeionization works (brief)

Electrodeionization (EDI) systems combine ion-exchange resins with ion-exchange membranes and an applied electrical field to continuously remove ionic contaminants from water. Unlike conventional mixed-bed deionizers that require chemical regeneration, EDI re-generates the resin in situ using an electric field, transporting ions to concentrate compartments for removal. For a technical overview, see the Electrodeionization article on Wikipedia.

Primary factors that affect EDI performance

EDI performance and lifecycle are driven by feedwater quality, pretreatment robustness, operational parameters (current density, flow, temperature), and the presence of foulants such as silica, organic carbon (TOC), iron, manganese, and colloidal material. Properly addressing these factors early reduces membrane fouling and extends stack life.

Typical performance targets

For ultrapure water applications the target resistivity is commonly 18.2 MΩ·cm at 25°C. Typical EDI outlets for polishing following reverse osmosis (RO) should maintain resistivity/conductivity, low TOC, and low silica to meet downstream requirements in semiconductor, pharmaceutical, or power plant uses. For general guidance on ultrapure water quality, see Ultrapure water.

Pretreatment Requirements and Their Impact on Lifecycle

Why pretreatment matters

EDI is sensitive to feedwater contaminants left untreated. RO, multimedia filtration, antiscalant dosing, and activated carbon are commonly used ahead of EDI. Effective pretreatment minimizes scaling, organic fouling, and particulate loading on membranes and resin, significantly extending stack life and reducing unplanned maintenance.

Recommended pretreatment train

A typical pretreatment sequence for EDI includes: sediment filtration (5–10 μm), activated carbon for chlorine/chloramines removal, reverse osmosis for bulk salt rejection, and antiscalant or pH adjustment for silica control. For many installations, a polished mixed-bed or ion-exchange softener upstream may be used where RO is not deployed.

Monitoring pretreatment effectiveness

Key parameters to monitor before the EDI unit include feed conductivity, silica, free/chlorine residual, total organic carbon (TOC), iron, and Silt Density Index (SDI). Set alarm thresholds (e.g., SDI > 3, free chlorine > 0.1 mg/L) to prevent irreversible damage to membranes and resins.

Routine Maintenance Practices for Reliable Operation

Daily and weekly checks

Daily checks should include feed and product conductivity/resistivity, flow rates, system pressures, and observation of power supply readings (current and voltage). Weekly tasks often include checking prefilters, verifying antiscalant dosing and RO performance, and reviewing alarm logs. Early detection prevents stack stress.

Monthly and quarterly tasks

Monthly: change/clean prefilters, record electrode and stack current densities, and sample product water for TOC and silica. Quarterly: inspect seal integrity, validate calibration of conductivity/resistivity meters, perform a more detailed sampling regime (RO permeate, EDI feed and product), and check for membrane discoloration or resin compaction.

Cleaning-in-place (CIP) and chemical cleaning

When fouling is detected (e.g., gradual rise in product conductivity or increased pressure drop), CIP protocols restore performance. Typical CIP chemistries target organics, iron, or silica and must be compatible with membranes and resin. Always follow manufacturer-recommended cleaning procedures and safety guidance.

Lifecycle Considerations: Components, Replacement Intervals, and Costs

Component lifetimes and indicators for replacement

- EDI stacks and membranes: typical useful life 5–10 years depending on feed quality and maintenance; replace earlier if irreversible performance loss (persistent low resistivity, excessive leakage) occurs.

- Resin inside EDI compartments: resin is continuously regenerated but may degrade with fouling; resin replacement is less frequent than membranes and is often performed during stack refurbishment.

- Power supplies and electrodes: expected life 7–15 years; monitor for corrosion, changes in current efficiency, or electrode degradation.

- Pre-treatment components (RO elements, filters, carbon): RO membranes often replaced every 3–7 years depending on feed and antiscalant program.

Lifecycle cost comparison

Below is a simplified comparison of lifecycle considerations for EDI vs. traditional mixed-bed deionization and RO alone. Values will vary by site and operating conditions.

| Metric | EDI (continuous, no chemical regen) | Mixed-bed DI (chemical regen) | RO (polishing varies) |

|---|---|---|---|

| Chemical use | Minimal/none | High (acid/base regeneration) | Low (cleaning only) |

| Typical maintenance frequency | Regular monitoring, CIP as needed | Frequent resin handling & regeneration cycles | RO element replacement 3–7 yrs |

| Downtime risk | Moderate (CIP/stack replacement) | Higher (regeneration outages) | Moderate (fouling/element change) |

| Operating cost drivers | Electricity; monitoring; occasional stack replacement | Chemicals; labor for regeneration | Energy for high pressure pumps; element replacement |

When to refurbish vs replace

Consider stack refurbishment when reversible fouling can be removed by CIP but permanent membrane damage or electrode corrosion is absent. Replace stacks when performance (product resistivity, salt passage) cannot be recovered or when physical damage is present. A cost-benefit analysis should weigh remaining expected life, cost of refurbishment, spare parts availability, and criticality of continuous ultrapure water supply.

Troubleshooting Common EDI Problems

Declining product resistivity

Common causes: increased feed conductivity, membrane fouling, air entrainment, or failing power supply. Immediate steps: verify feedwater conductivity and RO performance, inspect for air in inlet lines, and check current density and voltage. If conductivity rises despite correct operating current, schedule CIP or stack inspection.

Increased pressure drop across stack

Often due to particulate or biological fouling, resin compaction, or scale formation. Check prefilters and SDI; if prefilters are clean, perform recommended backflush/CIP. If pressure drop persists, disassemble and inspect stack for blocked flow channels or damaged spacers.

Electrode or membrane damage indicators

Signs include sudden loss of conductivity control, abnormal current draw, gas formation inside compartments, or visible discoloration. Immediately reduce or stop operation to prevent further damage and contact the EDI manufacturer or service partner for assessment.

Best Practices for Long-Term Reliability and Compliance

Implement a data-driven monitoring program

Continuous logging of conductivity/resistivity, temperature, flow, stack current density, and pressure drops is essential. Trend analysis reveals slow degradations before alarms trigger. Use redundancy in critical measurement points and perform regular calibration traceable to standards.

Scheduled preventive maintenance and spare parts

Maintain an inventory of critical spares: prefilters, conductivity probes, seals, and at least one spare EDI stack or a refurbishment contract to minimize downtime. Establish a PM schedule with quarterly and annual tasks and document all interventions in a maintenance log.

Regulatory and quality compliance

For pharmaceutical and semiconductor users, ensure EDI operation aligns with relevant standards and internal quality systems. Validate water quality per USP or industry-specific guidelines and keep records for audits. For regulatory context on water system best practices, consult authoritative organizations such as the U.S. EPA and industry associations (see U.S. EPA and American Water Works Association).

Brand Advantages: Electrodeionization Systems to Get UltraPure Water

Sustainability and cost-efficiency

Our Electrodeionization Systems to Get UltraPure Water eliminate the need for chemical regeneration, reducing hazardous chemical handling, storage and disposal costs. Over the lifecycle of the system, reduced chemical purchases and lower waste handling make EDI a sustainable choice for high-purity water production.

Design for uptime and ease of maintenance

Systems are engineered with modular stacks, accessible piping, and automated monitoring to simplify maintenance and streamline CIP operations. Modular design shortens service time and allows targeted stack replacement without complete system shutdown.

Support, validation and service

We provide commissioning, validation documentation, preventive maintenance plans, and on-site/service center refurbishments. Our support packages include remote monitoring options and training for facility personnel to ensure consistent compliance with water quality requirements.

Frequently Asked Questions (FAQ)

How often should EDI stacks be replaced?

Stack life depends on feedwater quality and maintenance. Typical life ranges from 5–10 years. With excellent pretreatment and proactive maintenance, some facilities achieve longer life. Replace stacks sooner if irreversible decline in ultrapure water quality or physical damage occurs.

Can EDI handle silica removal?

EDI can remove silica to an extent, but high silica loads or polymeric silica can foul membranes. For feeds with elevated silica, additional RO recovery optimization, antiscalant dosing, or silica-specific pretreatment (e.g., lime softening, ion exchange) may be required before the EDI stage.

What are the signs of membrane fouling vs. resin exhaustion?

Membrane fouling often presents as increased pressure drop, reduced current efficiency, or irreversible conductivity rise that does not respond to current adjustments. Resin issues typically arise from organic/colloidal fouling that reduces ionic transport and can often be partially reversed with CIP; however, resin does not undergo classical exhaustion due to continuous electrical regeneration.

How do I minimize downtime for critical processes?

Implement redundancy (parallel EDI stacks), maintain an inventory of critical spare parts, perform scheduled maintenance during low-production windows, and set up remote monitoring for early fault detection. Consider service contracts for rapid replacement or refurbishment.

Is EDI suitable for all ultrapure water applications?

EDI is ideal as a polishing step after RO for many high-purity applications (pharmaceutical, semiconductor, power). However, very high silica or organics may require specialized pretreatment. Site-specific water analysis is essential to confirm suitability.

In regulated industries, maintenance alone is not enough—buyers must also focus on validating electrodeionization systems for pharmaceutical water to meet GMP and compliance requirements.If you have more questions or need a site assessment to determine the right Electrodeionization Systems to Get UltraPure Water for your facility, contact our technical team or view the product details for specifications and service options.

References: Electrodeionization (Wikipedia) https://en.wikipedia.org/wiki/Electrodeionization; Ultrapure water (Wikipedia) https://en.wikipedia.org/wiki/Ultrapure_water; U.S. EPA https://www.epa.gov/.

Smart Water Purification Systems: Features and Benefits for Homes & Industry

RO vs UV vs Carbon: Which Water Purification System Wins?

Selecting the Right Commercial RO System for High-Capacity Needs

How to Maintain and Clean Your Water Softener System

Solutions

How often should I replace filters and membranes?

Filter and membrane lifespan depends on water quality, usage, and system type. General guidelines:

1. Sediment & Carbon Filters: Replace every 6–12 months.

2. RO Membranes: Replace every 2–3 years, depending on water conditions.

3. UF/NF Membranes: Replace every 1–2 years.

Regular maintenance ensures optimal performance and water quality.

Are AQT’s water treatment products certified?

Yes! Our products comply with international quality and safety standards, including ISO, CE, and NSF certifications. We prioritize high-quality materials, advanced technology, and strict quality control to ensure superior performance and reliability.

Blog

Can I use a water softener with a septic system?

Yes. Studies show no negative impact, especially when using metered regeneration systems.

How long does a water softener system last?

Most systems last 10–15 years with proper maintenance. Resin beads may need replacement after 8–10 years.

FAQ-aqualitek

What types of water treatment systems does AQT offer?

AQT provides a wide range of water purification solutions, including reverse osmosis (RO) systems, ultrafiltration (UF) systems, nanofiltration (NF) systems, deionization (DI) systems, electro-deionization (EDI) systems, chemical dosing systems, and water softeners. We also supply spare parts and components for water treatment systems.

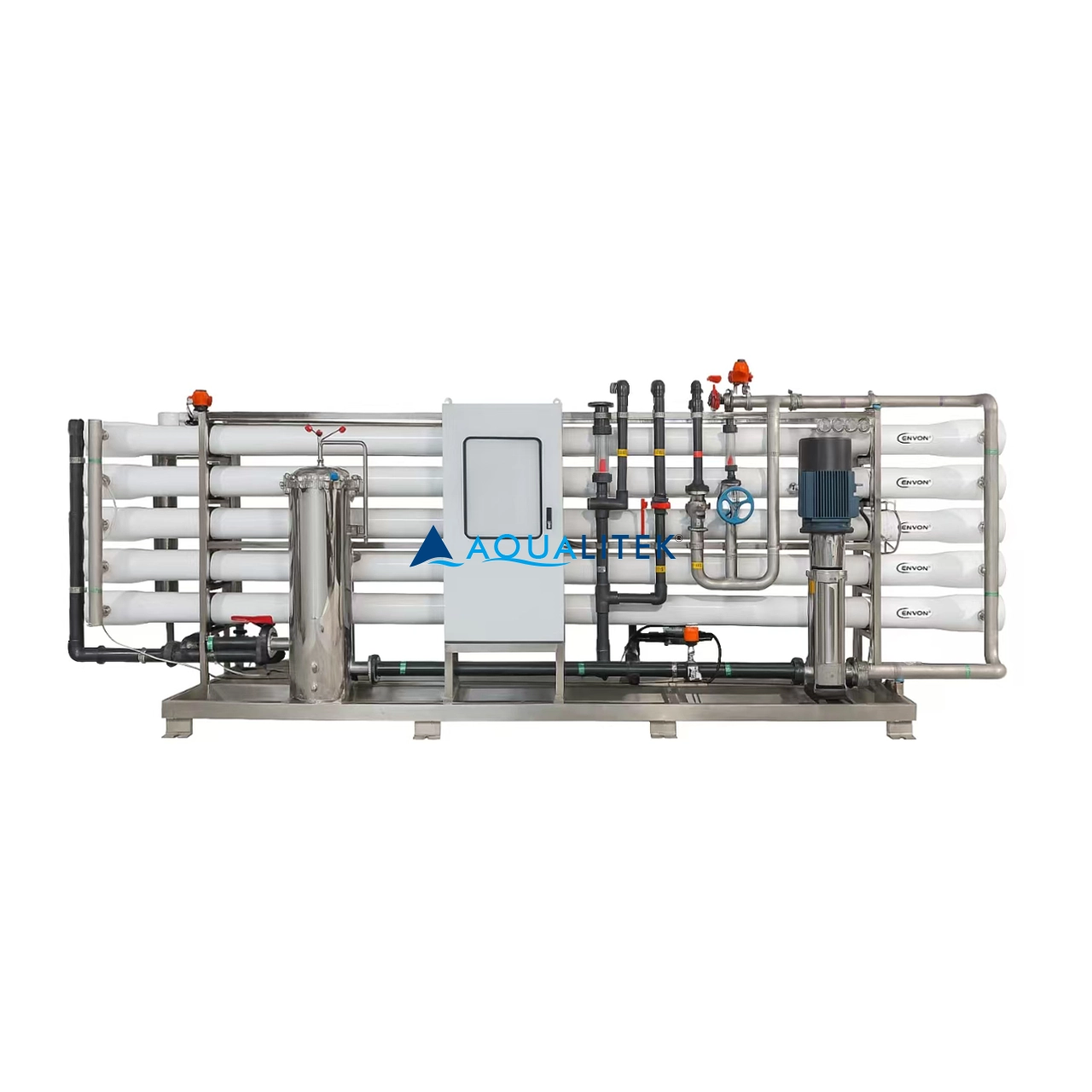

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWE Series

TWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for tap water (lower TDS). The large volumes can help meet your a variety of industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo