Optimizing BWRO BWE Performance: Pre-treatment for Well Water

- Optimizing BWRO BWE Performance: Pre-treatment for Well Water

- Understanding well water challenges for Water Treatment Systems for Well Water

- Why pre-treatment matters for Brackish Water Reverse Osmosis (BWRO) Systems BWE Series

- Core pre-treatment steps for well water using BWRO BWE Series

- Pre-treatment component details and commercial considerations

- Coarse screening and sediment control

- Multi-media filtration

- Cartridge filtration

- Iron and manganese removal

- Hardness control and antiscalant dosing

- Biological control and disinfection

- Pre-treatment comparison table

- Monitoring and operational best practices for BWRO BWE Series

- Troubleshooting common well water feed issues

- How pre-treatment improves lifecycle and economics for the BWE Series

- Matching pre-treatment to BWE Series: practical recommendations

- Brand advantages: why select our Brackish Water Reverse Osmosis (BWRO) Systems BWE Series

- Example: estimated impact of pre-treatment on operating cost

- FAQs

- Contact us / View product

- References and authoritative resources

- Authority references (for design validation)

Optimizing BWRO BWE Performance: Pre-treatment for Well Water

Understanding well water challenges for Water Treatment Systems for Well Water

Well water supplies are highly variable. Groundwater can contain elevated levels of dissolved solids (TDS), hardness (calcium and magnesium), iron and manganese, dissolved gases, organic matter, turbidity from sand and silt, and biological activity. For operators selecting Water Treatment Systems for Well Water, these variabilities translate directly into membrane fouling, scaling, increased cleaning frequency, higher operating costs, and reduced membrane life if pre-treatment is inadequate.

Why pre-treatment matters for Brackish Water Reverse Osmosis (BWRO) Systems BWE Series

Brackish Water Reverse Osmosis (BWRO) Systems BWE Series are engineered to deliver high recovery and low operating costs for higher-TDS sources, but membranes are sensitive to feedwater quality. Effective pre-treatment protects membranes from particulate fouling, organic and biological fouling, iron/manganese precipitation, and inorganic scaling. Investing in correct pre-treatment reduces downtime, chemical expenses, and overall total cost of ownership while ensuring the BWE Series meets delivery and quality targets.

Core pre-treatment steps for well water using BWRO BWE Series

Most robust pre-treatment strategies for well water combine mechanical, chemical, and operational controls. The primary steps are:

- Screening and coarse sediment removal to protect pumps and piping

- Multi-media or sand filtration to remove suspended solids down to 5-10 microns

- Cartridge filtration to polish to 1-5 microns ahead of membrane housings

- Iron and manganese removal where concentrations exceed 0.1 mg/L

- Water softening or antiscalant dosing when hardness and alkalinity would cause scale at target recoveries

- Disinfection or biofiltration control where biological growth elevates fouling risk

Pre-treatment component details and commercial considerations

When specifying Water Treatment Systems for Well Water, understanding the pros, cons, and of key components helps operators pick the right combination for BWE Series systems:

Coarse screening and sediment control

Coarse screens and vortex separators remove large debris and protect downstream equipment. These are low-cost, low-maintenance safeguards that reduce abrasion and clogging risks for pumps and filters.

Multi-media filtration

Multimedia filters (sand, anthracite) are effective for turbid sources and remove most particulates that cause membrane plugging. They are economical for handling variable turbidity and extend cartridge life upstream of the BWRO BWE Series.

Cartridge filtration

Final cartridge filters (1–5 micron) are critical immediately upstream of membrane housings. They remove fine particulates and protect membranes from irreversible fouling. For brackish feeds with silt or iron fines, change frequency is dictated by differential pressure rise and particulate load.

Iron and manganese removal

Well water often contains dissolved ferrous iron and manganese. When oxidized, these precipitate and foul membranes. Typical treatment includes oxidation (air/chemical) followed by filtration or greensand and catalytic media. If iron >0.1 mg/L, pre-treatment is recommended before BWRO BWE Systems to prevent membrane fouling and staining.

Hardness control and antiscalant dosing

High carbonate hardness and alkalinity increase scale risk at elevated recoveries. Chemical antiscalants tailored to the water chemistry are the industry-preferred option for many BWRO plants because they allow higher recoveries without the footprint of ion-exchange softeners. In cases of extreme hardness, water softening may be required. Design for a safety margin: predict scaling indices (Langelier Saturation Index, Stiff & Davis) and dose antiscalant accordingly.

Biological control and disinfection

Heterotrophic bacteria and biofilms can form on membranes and feed components. UV disinfection, controlled chlorination followed by dechlorination, or biofiltration can keep microbial growth manageable. Avoid residual oxidants at the membrane unless using oxidation-resistant membranes or neutralizing downstream.

Pre-treatment comparison table

The table below summarizes common pre-treatment options for well water applied to BWRO BWE Series selection.

| Pre-treatment | Primary Target | Typical Maintenance | Pros | Cons |

|---|---|---|---|---|

| Coarse screening | Large debris, leaves | Monthly inspection, occasional cleaning | Low cost, protects equipment | Not effective for fine particulates |

| Multi-media filter | Turbidity, suspended solids 10–50 µm | Backwash weekly to monthly | Robust, economical for variable loads | Requires backwash handling |

| Cartridge filters (1–5 µm) | Fine particulates, polishing | Replace based on DP rise (weeks–months) | Critical for membrane protection | Recurring consumable cost |

| Oxidation + media (iron removal) | Dissolved iron/manganese | Periodic backwash, media replacement | Prevents iron fouling and staining | Requires chemical handling or aeration |

| Antiscalant dosing | Scaling species (CaCO3, BaSO4, etc.) | Regular chemical feed checks | Enables higher recovery, small footprint | Ongoing chemical cost, dosing control needed |

| UV / chlorination | Microbial control | Lamp replacement, residual testing | Effective bio-control | Chlorine must be removed before RO membranes |

Monitoring and operational best practices for BWRO BWE Series

Operational discipline gives the best ROI on pre-treatment investment. Key parameters to monitor:

- SDI or MFI to track particulate fouling potential — target SDI < 3 for most BWRO membranes

- Feed TDS and conductivity — helps calculate salt rejection and recovery

- pH, alkalinity, and hardness — used to calculate scaling indices

- Iron and manganese levels — ensure below threshold for membranes

- Pressure differentials across pre-filters and membranes — early warning for fouling

- Flows and recovery — verify system operates at design setpoints

Troubleshooting common well water feed issues

Problem: Rapid pressure rise across cartridges and membranes. Likely cause: particulate surge or inadequate upstream filtration. Action: inspect prefilters, check SDI, backwash multimedia filters, increase cartridge change frequency.

Problem: Progressive decline in permeate quality or flux drop with low SDI. Likely cause: scaling or chemical incompatibility. Action: review hardness/alkalinity, calculate scaling indices, check antiscalant feed and dosing control, consider lowering recovery or carry out chemical cleaning.

Problem: Brown/red staining on membranes or deposits. Likely cause: iron breakthrough. Action: verify iron removal stage operation, inspect for anaerobic conditions in wells, adjust oxidation and filtration steps.

How pre-treatment improves lifecycle and economics for the BWE Series

Better pre-treatment translates to fewer clean-in-place (CIP) cycles, lower chemical consumption, and longer membrane life. For example, reducing fouling frequency from quarterly to annual can lower operating expense by tens of percent depending on plant size. The BWE Series is optimized for large volumes and high recovery; pairing it with robust pre-treatment avoids the common trade-off between high recovery and frequent cleaning.

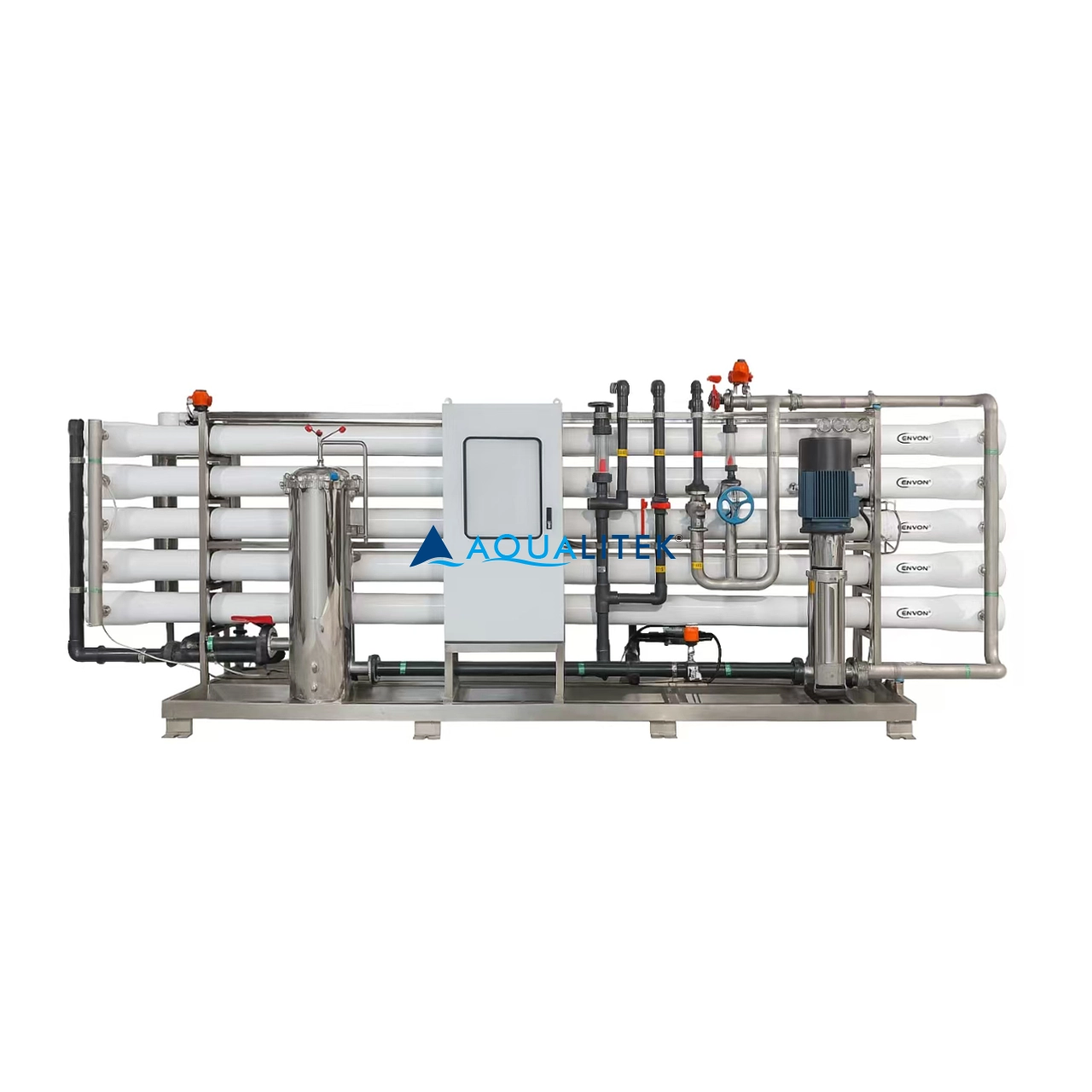

BWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for brackish water(higher TDS).The large volumes can help meet your a variety of industrial applications.T hey are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Matching pre-treatment to BWE Series: practical recommendations

For a typical brackish well feed (TDS 2,000–8,000 mg/L) intended for a BWE Series skid operating at 75–85% recovery, recommended baseline pre-treatment is:

- Coarse screen at intake

- Multi-media filter sized for expected turbidity with automatic backwash

- Oxidation + media filter when iron/manganese >0.1 mg/L

- Cartridge filters 1–5 µm immediately before RO

- Antiscalant dosing sized from lab or software scaling prediction

- UV or controlled disinfection where biological growth is present

Brand advantages: why select our Brackish Water Reverse Osmosis (BWRO) Systems BWE Series

Our BWRO BWE Series offers the following advantages when combined with recommended pre-treatment for well water:

- Pre-engineered skid reduces commissioning time and field labor

- Eight membrane housings give flexibility in array configuration and staged recovery

- Designed for high recovery to lower waste brine volume and operating cost

- Optimized flow paths and pressure profiles reduce energy consumption

- Low maintenance philosophy: simplified access, standardized spare parts

- Field-proven compatibility with common pre-treatment modules and antiscalant dosing systems

Example: estimated impact of pre-treatment on operating cost

Consider a mid-size BWE Series installation producing 50 m3/day from a well with moderate turbidity and hardness. The table below shows illustrative annual operating impacts; numbers are indicative and should be validated for each site.

| Scenario | Annual CIP frequency | Annual chemical cost | Membrane replacement interval | Estimated OPEX change |

|---|---|---|---|---|

| Minimal pre-treatment | 4 times | High | 3–4 years | Higher OPEX |

| Optimized pre-treatment | 1 time | Moderate | 7–10 years | Lower OPEX (30–50% reduction) |

FAQs

Q: What SDI should I aim for before the BWE Series?

A: Aim for SDI < 3; many operators prefer SDI < 2.5 to maximize membrane life and minimize fouling risk.

Q: Can I rely on antiscalant alone instead of softening?

A: For most brackish systems, antiscalant dosing is an effective, lower-footprint approach allowing higher recovery. Softening is recommended where hardness is extreme or when barium/strontium scaling risk is high.

Q: How often should cartridges be changed?

A: Change based on differential pressure rise or a scheduled interval. Typical intervals range from weeks to months, depending on particulate load and multimedia filter performance.

Q: What if my well has intermittent sand surges?

A: Install coarse settling or a sand trap ahead of media filters, and consider automatic backwashing filters and redundant cartridge skids for continuous operation.

Q: How does pre-treatment affect warranty and service?

A: Manufacturers often require adherence to recommended pre-treatment and monitoring practices to maintain warranty coverage. Proper pre-treatment reduces service calls and prevents warranty-voiding damage.

Contact us / View product

To discuss pre-treatment design for your well and to see how Brackish Water Reverse Osmosis (BWRO) Systems BWE Series can meet your requirements, contact our sales team or request a customized quotation. View product details and request a quote on our product page or call our technical sales for a feedwater review and system proposal. Effective pre-treatment also minimizes long-term system risks. Implementing robust scaling and fouling control strategies for BWRO BWE systems helps protect membranes and maintain consistent permeate flow.

References and authoritative resources

- United States Environmental Protection Agency, Ground Water and Drinking Water: https://www.epa.gov/ground-water-and-drinking-water

- World Health Organization, Drinking-water: https://www.who.int/news-room/fact-sheets/detail/drinking-water

- Reverse osmosis, Wikipedia: https://en.wikipedia.org/wiki/Reverse_osmosis

- International Desalination Association: https://idadesal.org/

- American Water Works Association: https://www.awwa.org/

- NSF International, Water treatment certification: https://www.nsf.org/

Authority references (for design validation)

Designers and operators should consult local regulations and these authoritative sources for detailed guidance on drinking and industrial water treatment standards and for the latest membrane best practices.

500 LPH Reverse Osmosis TWV - 412 (RO): In-Depth Review

Energy Efficiency Tips for Commercial Reverse Osmosis Systems

Choosing Filtration Systems for Sediment and Turbidity

Industrial Reverse Osmosis Machine Costs 2026

FAQ-aqualitek

What industries does AQT serve?

We provide water treatment solutions for a wide range of industries, including:

Industrial Manufacturing – Process water treatment, cooling water, and boiler feed.

Hospitality & Commercial – Hotels, restaurants, and office buildings.

Residential Applications – Drinking water purification and softening.

Healthcare & Pharmaceuticals – Ultra-pure water for laboratories and hospitals.

Municipal & Public Utilities – Water supply and wastewater treatment.

Food & Beverage Processing – Filtration for beverage production and food safety.

Solutions

Can AQT provide custom water treatment solutions?

Yes! We specialize in OEM/ODM water treatment solutions and can design custom filtration systems tailored to your business, industry, or brand requirements. Our team can assist with system design, branding, private labeling, and technical support.

Can I use AQT’s water treatment systems for seawater desalination?

Yes! We provide seawater desalination systems using advanced reverse osmosis (RO) technology, specifically designed to convert seawater into fresh, drinkable water. These systems are ideal for coastal communities, marine applications, and industrial desalination projects.

Are AQT’s water treatment products certified?

Yes! Our products comply with international quality and safety standards, including ISO, CE, and NSF certifications. We prioritize high-quality materials, advanced technology, and strict quality control to ensure superior performance and reliability.

What is the difference between Reverse Osmosis (RO), Ultrafiltration (UF), and Nanofiltration (NF)?

1. Reverse Osmosis (RO): Removes up to 99.9% of contaminants, including salts, bacteria, viruses, and heavy metals.

2. Ultrafiltration (UF): Uses a membrane filtration process to remove bacteria and particles, while retaining essential minerals.

3. Nanofiltration (NF): Falls between RO and UF, removing some salts and organic compounds while allowing certain minerals to pass through.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

30TPH Industrial Reverse Osmosis (RO) System

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

500LPH Panel Mounted Reverse Osmosis Water Purification System

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

Electrodeionization Systems to Get UltraPure Water

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo