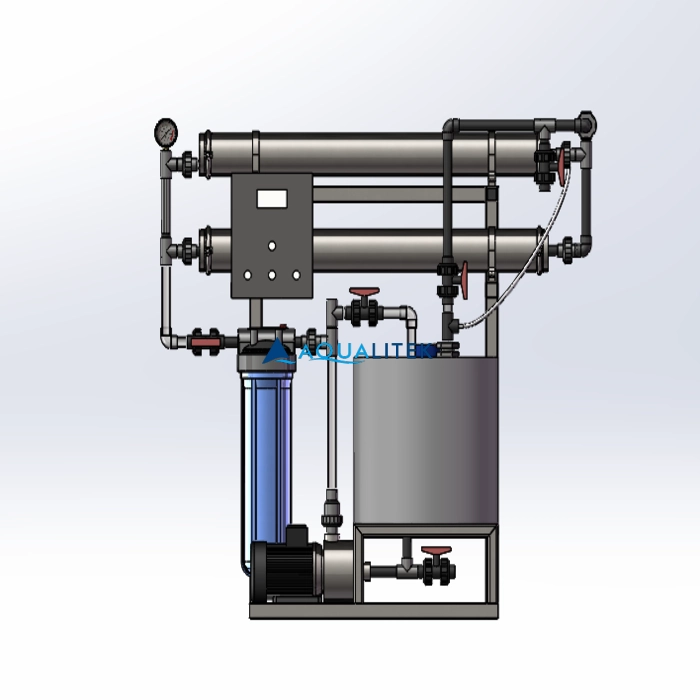

AQUALITEK Membrane Cleaning Systems - Reliable CIP Solutions

AQUALITEK Membrane Cleaning Systems

Company Overview

AQUALITEK (Aqualitek Water Treatment Technologies Co., Ltd.), headquartered in Guangzhou, China, specializes in advanced water treatment and membrane cleaning systems. Leveraging engineering expertise and manufacturing excellence, AQUALITEK delivers tailored cleaning solutions for RO, UF, NF and MBR membranes across residential, commercial and industrial applications.

Applications and Use Cases

Engineered for versatility, our membrane cleaning systems are suitable for potable water plants, food and beverage, pharmaceuticals, wastewater recycling and industrial process water. AQUALITEK systems support routine CIP (clean-in-place) cycles, emergency cleaning and pre/post-treatment optimization to maintain flux and permeate quality.

Core Benefits

AQUALITEK membrane cleaning systems extend membrane life, reduce fouling, minimize chemical consumption and restore performance quickly. Customers gain measurable benefits: lower operating costs, reduced downtime, improved water recovery and consistent product quality—backed by data-driven diagnostics and control strategies.

Technical Features

Our systems integrate precision dosing, programmable cleaning sequences, automated recirculation and monitoring for pH, conductivity and flow. Materials and components are selected for chemical compatibility and longevity. Optional modules include heat-assisted cleaning, enzyme dosing and ultrasonic enhancement for hard-to-remove foulants.

Customization and Support

AQUALITEK provides turnkey solutions: site assessment, pilot testing, engineered skid systems and after-sales service. We customize cleaning protocols, chemical recipes and control logic to match feedwater conditions and membrane chemistry, ensuring safe and effective cleaning cycles.

Why Choose AQUALITEK

With global delivery capabilities and a commitment to sustainability, AQUALITEK combines innovative design, reliable components and responsive technical support. Choose AQUALITEK membrane cleaning systems for scalable, cost-effective cleaning strategies that protect assets and optimize water treatment performance.

Can AQT provide custom water treatment solutions?

Yes! We specialize in OEM/ODM water treatment solutions and can design custom filtration systems tailored to your business, industry, or brand requirements. Our team can assist with system design, branding, private labeling, and technical support.

Can I automate the filter cleaning process?

Absolutely. Our automatic backwash filters come with timer-based or differential pressure-triggered controls.

How do I choose the right water treatment system for my needs?

The choice depends on factors such as water quality, application, flow rate, and purification requirements. Our team of experts can analyze your water source and recommend the most suitable solution for residential, commercial, or industrial applications.

What is the expected lifespan of a water filter?

Cartridge filters generally last 1–3 months. Media filters require periodic backwashing and media replacement every 1–2 years, depending on usage.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

500LPH Panel Mounted Reverse Osmosis Water Purification System

500LPH Panel Mounted Reverse Osmosis Water Purification System

Melt Blown PP Filter Cartridge | PP Sediment Filter for RO Pretreatment

Melt Blown PP Filter Cartridge | PP Sediment Filter for RO Pretreatment

500 liters per hour multi-stage water filtration and softening system

500 liters per hour multi-stage water filtration and softening system

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

Tap Water Reverse Osmosis (TWRO) Systems TWE Series

Tap Water Reverse Osmosis (TWRO) Systems TWE Series

Brackish Water Reverse Osmosis (BWRO) Systems BWE Series

Brackish Water Reverse Osmosis (BWRO) Systems BWE Series

Brackish Water Reverse Osmosis (BWRO) Systems BWF Series

Brackish Water Reverse Osmosis (BWRO) Systems BWF Series

Sea Water Reverse Osmosis (SWRO) systems SWH Series

Sea Water Reverse Osmosis (SWRO) systems SWH Series

Sea Water Reverse Osmosis (SWRO) Systems SWE Series

Sea Water Reverse Osmosis (SWRO) Systems SWE Series

Durable UF System with Backflush for High-Turbidity Surface Water Ultrafiltration (UF) Water System

Durable UF System with Backflush for High-Turbidity Surface Water Ultrafiltration (UF) Water System

High-Capacity UF Machine for Industrial Process Water Treatment

High-Capacity UF Machine for Industrial Process Water TreatmentRequest More Products Information

Submit your inquiry now to receive detailed specifications, pricing, and tailored solutions from our professional team.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo