Top 10 reverse osmosis system Manufacturers and Supplier Brands

- Top 10 Reverse Osmosis System Manufacturers and Supplier Brands

- Why you searched for reverse osmosis system manufacturers

- How to evaluate reverse osmosis system suppliers

- Top 10 reverse osmosis system manufacturers and suppliers

- 1. DuPont Water Solutions (FilmTec) — Membrane technology leader

- 2. Toray Industries — High-performance RO membranes and modules

- 3. Hydranautics (Nitto Denko) — Technical membranes and OEM support

- 4. SUEZ/Veolia (formerly GE Water) — Industrial system integrator and membranes

- 5. Pentair — Residential to commercial RO systems and components

- 6. Culligan — Service-driven residential and commercial RO solutions

- 7. Kinetico — Non-electric and residential RO systems with strong after-sales

- 8. Aquatech — Engineered industrial RO and desalination plants

- 9. Koch Membrane Systems — Advanced membranes and process solutions

- 10. Aqualitek Water Treatment Technologies Co., Ltd. (AQT) — Custom RO systems and components

- How these manufacturers differ: technology, scope, and support

- Membrane makers vs. system integrators

- Residential/commercial vs. industrial focus

- Service network and spare parts availability

- Comparative summary: Top 10 reverse osmosis system offerings

- At-a-glance product and application comparison

- How to pick the right reverse osmosis system partner

- Define feedwater and performance targets

- Consider lifecycle cost, not just CAPEX

- Ask for references and performance guarantees

- Conclusion: matching supplier strengths to your project needs

- Choose by needs—membranes, systems, or service

- Final recommendation

- Frequently Asked Questions

Top 10 Reverse Osmosis System Manufacturers and Supplier Brands

Why you searched for reverse osmosis system manufacturers

When prospective buyers search for reverse osmosis system manufacturers and suppliers, their intent is usually commercial: to compare product quality, membrane technology, service networks, and customization options for residential, commercial, or industrial projects. This article helps procurement managers, plant engineers, and business owners quickly evaluate the leading RO brands, understand product focus, and make an informed purchasing decision.

How to evaluate reverse osmosis system suppliers

Key selection criteria for a reverse osmosis system supplier include membrane technology and rejection rates, system design and recovery, pretreatment compatibility, service and spare-part availability, customization capability, and total cost of ownership. We'll discuss each manufacturer's strengths relevant to those criteria so you can match suppliers to project requirements.

Top 10 reverse osmosis system manufacturers and suppliers

1. DuPont Water Solutions (FilmTec) — Membrane technology leader

DuPont's FilmTec brand is one of the most widely specified reverse osmosis membranes in the world. While primarily known for high-performance RO membrane elements, DuPont supports system manufacturers and EPCs with technical guidance and element warranties. FilmTec membranes are used across residential, municipal, brackish water, and seawater desalination applications due to consistent salt rejection (typically 95–99% for brackish RO membranes) and reliable flux performance.

2. Toray Industries — High-performance RO membranes and modules

Toray supplies polymeric RO membranes and complete modules widely adopted for municipal, industrial, and desalination use. Toray membranes are recognized for stable flux profiles, good fouling resistance, and global availability. Toray also partners with system integrators to deliver packaged reverse osmosis systems for water reuse, boiler feed, and process water applications.

3. Hydranautics (Nitto Denko) — Technical membranes and OEM support

Hydranautics, a Nitto Denko company, manufactures spiral-wound RO and NF membrane elements for brackish and seawater treatment. Their product range covers low-pressure residential membranes to high-pressure desalination elements. Hydranautics supports OEMs with long-term element performance data and fouling-mitigation guidelines, which are valuable in system design and lifecycle planning.

4. SUEZ/Veolia (formerly GE Water) — Industrial system integrator and membranes

SUEZ/Veolia is a global player in industrial and municipal water treatment, offering integrated RO systems, membranes, and after-sales services. They provide engineered plants for desalination, wastewater reuse, and industrial process water, including pretreatment and post-treatment that optimize RO system longevity. Their global service footprint is an advantage for large-scale, multi-site projects.

5. Pentair — Residential to commercial RO systems and components

Pentair offers a wide portfolio of reverse osmosis solutions for homes, restaurants, and commercial applications, including membrane elements, housings, and complete packaged units. Pentair emphasizes ease of installation, reliable filtration performance, and established distribution channels—making them a common choice for point-of-use and small-scale commercial RO needs.

6. Culligan — Service-driven residential and commercial RO solutions

Culligan pairs branded reverse osmosis systems with a large service and dealer network. They focus on customer service, maintenance contracts, and financing options, which is helpful for businesses that prefer managed water services. Culligan supplies residential RO systems, commercial countertop and under-sink units, and larger commercial systems for offices and small foodservice operations.

7. Kinetico — Non-electric and residential RO systems with strong after-sales

Kinetico designs water treatment systems for households and light commercial use, including reverse osmosis solutions. Known for robust, low-maintenance designs, Kinetico emphasizes user-friendly operation and dealer-supported installation and maintenance. Their systems are often chosen where reliability and minimal service downtime matter.

8. Aquatech — Engineered industrial RO and desalination plants

Aquatech specializes in engineered water treatment projects including high-capacity reverse osmosis systems, seawater desalination, brackish RO, and zero-liquid-discharge (ZLD) integrations. They work on large industrial and municipal contracts, providing turnkey solutions, process guarantees, and site commissioning services—suitable for heavy industrial users and utilities.

9. Koch Membrane Systems — Advanced membranes and process solutions

Koch Membrane Systems (KMS) provides membrane products and integrated RO/NF systems targeting industrial separation applications. KMS develops specialized membrane materials and modules that address challenging feedwaters, high recovery operations, and niche chemical compatibility requirements. Their R&D focus helps when your project requires non-standard membrane performance.

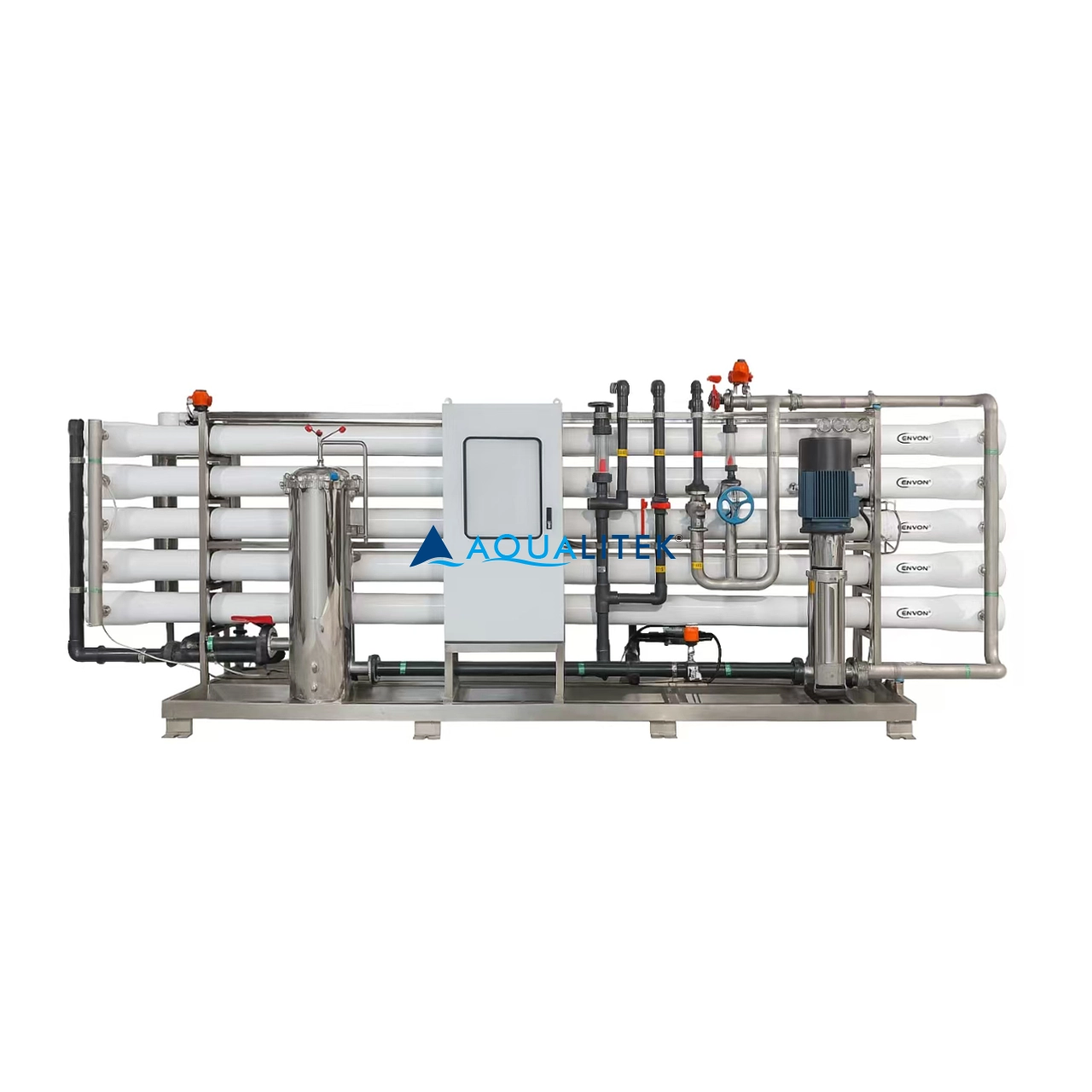

10. Aqualitek Water Treatment Technologies Co., Ltd. (AQT) — Custom RO systems and components

Aqualitek (AQT), headquartered in Guangzhou, China, is a leading manufacturer and supplier of advanced water treatment systems and high-quality component parts. AQT specializes in delivering customized reverse osmosis system solutions for residential, commercial, and industrial applications worldwide. With strong engineering expertise, modern manufacturing, and a structured product portfolio—from pretreatment equipment to core RO units and end-use recycling systems—AQT is positioned to provide efficient, reliable, and sustainable RO systems with competitive lead times and local/global support options.

How these manufacturers differ: technology, scope, and support

Membrane makers vs. system integrators

Some companies primarily manufacture membranes (e.g., DuPont FilmTec, Toray, Hydranautics), while others provide fully integrated RO systems and plant-level services (e.g., SUEZ/Veolia, Aquatech, Aqualitek). If you need membrane-level R&D or element warranties, choose a membrane specialist. If you need turnkey installation, automation, and long-term service, choose a system integrator.

Residential/commercial vs. industrial focus

Brands such as Pentair, Culligan, and Kinetico focus on residential and light commercial RO systems and dealer networks, offering ease of purchase and local maintenance. Companies like Aquatech, SUEZ/Veolia, and Aqualitek target industrial and municipal projects that require engineering, process guarantees, and site commissioning.

Service network and spare parts availability

Global service coverage and spare parts availability are critical for minimizing downtime. Large global suppliers maintain regional warehouses for membranes and cartridges. For remote or multi-site installations, prefer vendors with local partners or authorized service dealers to ensure timely support and regular maintenance.

Comparative summary: Top 10 reverse osmosis system offerings

At-a-glance product and application comparison

Below is a concise comparison of the top ten brands and their product emphasis to help you shortlist candidates based on project type, capacity, and support model.

| Brand | Primary RO Offering | Typical Applications | Strengths | Best for |

|---|---|---|---|---|

| DuPont (FilmTec) | Spiral-wound RO membranes/elements | Residential to industrial membranes, brackish RO | Proven membrane performance, global availability | OEMs and performance-critical projects |

| Toray | RO membranes and modules | Municipal, industrial, desalination | High-performance membranes, R&D | Large-scale and high-recovery projects |

| Hydranautics (Nitto Denko) | Membrane elements and modules | Brackish, seawater, wastewater reuse | Technical support, fouling data | Projects needing expert membrane guidance |

| SUEZ / Veolia | Turnkey RO systems and services | Municipal desalination, industrial plants | Full-service EPC, global service network | Large, multisite installations |

| Pentair | Residential/commercial RO units & components | Under-sink, point-of-use, small commercial | Easy installation, reliable distribution | Retail and light commercial buyers |

| Culligan | Packaged RO systems with service plans | Residential, offices, small industry | Service-driven model, dealer network | Buyers who value ongoing service |

| Kinetico | Point-of-use and residential RO systems | Homes, small commercial sites | Durable, low-maintenance systems | Homeowners and small businesses |

| Aquatech | Engineered industrial RO and desalination | Industrial process water, ZLD projects | Turnkey engineered solutions | Large industrial desalination and reuse |

| Koch Membrane Systems | Membranes and integrated modules | Specialty industrial separations | R&D-driven membrane solutions | Challenging feedwater and niche uses |

| Aqualitek (AQT) | Custom RO systems and component parts | Residential, commercial, industrial | Cost-effective customization, manufacturing capacity | Buyers needing tailored solutions and global supply |

How to pick the right reverse osmosis system partner

Define feedwater and performance targets

Start with a precise feedwater analysis (TDS, SDI, organics, hardness, iron, silica, chlorine, etc.) and desired permeate quality. That will determine membrane selection (brackish vs. seawater), pretreatment needs, and expected recovery rates—core determinants of system cost and supplier suitability.

Consider lifecycle cost, not just CAPEX

Compare energy consumption, chemical cleaning frequency, membrane replacement costs, and maintenance agreements. Lower initial cost suppliers may have higher operating costs later; conversely, established membrane brands and integrated service can reduce unplanned downtime and operating expense.

Ask for references and performance guarantees

Request project references of similar capacity and feedwater, and ask suppliers for guaranteed performance curves and site acceptance tests. For critical industrial or municipal projects, insist on contractual performance guarantees tied to penalties if guarantees are missed.

Conclusion: matching supplier strengths to your project needs

Choose by needs—membranes, systems, or service

Choosing the right reverse osmosis system supplier depends on project scale and priorities. If you require best-in-class membrane elements, DuPont, Toray, or Hydranautics are proven choices. For turnkey, engineered desalination or industrial reuse projects, SUEZ/Veolia, Aquatech, or Aqualitek provide full-service capabilities. For residential and small commercial installations, Pentair, Culligan, and Kinetico offer strong channel support and easy maintenance. Review pretreatment, warranty terms, and local service availability before finalizing.

Final recommendation

For buyers needing a combination of manufacturing scale, competitive pricing, and customization—particularly for global projects—Aqualitek (AQT) is a supplier to consider. AQT delivers tailored RO systems, robust component sourcing, and engineering support suitable for households to large industrial applications. Request detailed proposals, pilot testing, and lifecycle cost comparisons from shortlisted suppliers to make an evidence-based choice.

Frequently Asked Questions

Q: What removal rates can I expect from a reverse osmosis system?A: Typical brackish RO membranes remove 95–99% of dissolved salts (TDS), while seawater RO membranes are designed for higher-pressure applications. Exact rejection depends on membrane type, operating pressure, temperature, and feedwater composition.

Q: How important is pretreatment for an RO system?A: Pretreatment is critical. Proper filtration, softening or antiscalant dosing, and chlorine removal protect membranes from fouling and scaling, reduce chemical cleaning frequency, and extend membrane life.

Q: How often do RO membranes need replacement?A: Membrane lifespan varies with feedwater and maintenance but commonly ranges from 3 to 7 years for industrial systems and longer for well-maintained municipal systems. Regular monitoring and cleaning can extend life.

Q: Should I buy membranes from a membrane specialist or a packaged system from an integrator?A: If you have in-house engineering and want to design custom trains, buy membranes from specialist manufacturers (DuPont, Toray). If you need turnkey installation and ongoing service, choose an integrator (Aqualitek, Aquatech, SUEZ/Veolia).

Q: What is the best way to evaluate suppliers' claims?A: Request feedwater-specific pilot tests, ask for third-party performance data, and verify references of completed projects with similar conditions and capacity. Also confirm warranty terms and service response times.

Selecting the Right BWRO BWE System for Your Well Water Needs

Key Specs to Evaluate in an Industrial RO System Purchase

Benefits of Brackish Water Reverse Osmosis for Well Water

Energy Efficiency Tips for Commercial Reverse Osmosis Systems

Membrane Water Treatment Systems

Do you offer plug-and-play solutions?

Absolutely. We offer containerized membrane systems that are factory-tested, compact, and quick to deploy.

Water Filters

What is the expected lifespan of a water filter?

Cartridge filters generally last 1–3 months. Media filters require periodic backwashing and media replacement every 1–2 years, depending on usage.

Solutions

Can AQT provide custom water treatment solutions?

Yes! We specialize in OEM/ODM water treatment solutions and can design custom filtration systems tailored to your business, industry, or brand requirements. Our team can assist with system design, branding, private labeling, and technical support.

FAQ-aqualitek

What industries does AQT serve?

We provide water treatment solutions for a wide range of industries, including:

Industrial Manufacturing – Process water treatment, cooling water, and boiler feed.

Hospitality & Commercial – Hotels, restaurants, and office buildings.

Residential Applications – Drinking water purification and softening.

Healthcare & Pharmaceuticals – Ultra-pure water for laboratories and hospitals.

Municipal & Public Utilities – Water supply and wastewater treatment.

Food & Beverage Processing – Filtration for beverage production and food safety.

Ion Exchange Water Treatment Systems

Are mixed bed systems better than two-bed systems?

Mixed bed polishers are used for final polishing after RO or two-bed deionization to achieve ultra-pure water.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWE Series

TWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for tap water (lower TDS). The large volumes can help meet your a variety of industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo