Troubleshooting BWRO BWE Systems: Solving Well Water Issues

- Troubleshooting BWRO BWE Systems: Solving Well Water Issues

- Why proper troubleshooting matters for Water Treatment Systems for Well Water

- Product overview: Brackish Water Reverse Osmosis (BWRO) Systems BWE Series

- Initial check: symptoms, data collection and safety

- Diagnostic checklist

- Common problem 1: Low permeate flow or low recovery

- Step-by-step resolution

- Common problem 2: High permeate conductivity (salt passage)

- Troubleshooting steps

- Common problem 3: Iron, manganese, and hydrogen sulfide (H2S)

- Treatment approaches

- Common problem 4: Biological fouling (biofouling)

- Diagnosis and corrective actions

- Common problem 5: Scaling and hardness-related issues

- Prevention and remediation

- Monitoring and instrumentation best practices for BWRO BWE Series

- Chemical cleaning protocols (CIP) — safe and effective methods

- Optimization tips: balancing recovery, energy, and longevity

- Maintenance schedule and spare parts strategy

- When to call technical support or replace membranes

- Brand value: Why choose BWE Series for well water BWRO applications

- Frequently Asked Questions (FAQ)

- Q1: How often should I perform CIP on BWE Series systems?

- Q2: Can BWRO BWE Series handle high-iron well water?

- Q3: What cleaning chemicals are safe for BWE Series membranes?

- Q4: How do I reduce scaling when feedwater hardness is high?

- Q5: What routine instruments are most valuable?

- Contact us / View Product

- Authoritative references

Troubleshooting BWRO BWE Systems: Solving Well Water Issues

Why proper troubleshooting matters for Water Treatment Systems for Well Water

Well water has a wide range of characteristics—high total dissolved solids (TDS), iron, hardness, manganese, organics, turbidity, and microbiological content—that can challenge any brackish water reverse osmosis setup. For plants using Brackish Water Reverse Osmosis (BWRO) Systems BWE Series, rapid and accurate troubleshooting reduces downtime, prevents irreversible membrane damage, and preserves recovery and product water quality. This article gives field-tested diagnostics and corrective measures tailored to BWRO BWE Series units to help operators resolve the most common well water problems. Once issues are resolved and performance restored, it’s worth revisiting the core treatment principles. This brings the focus back to how the BWRO BWE series treats high-TDS well water effectively, completing a closed-loop optimization strategy.

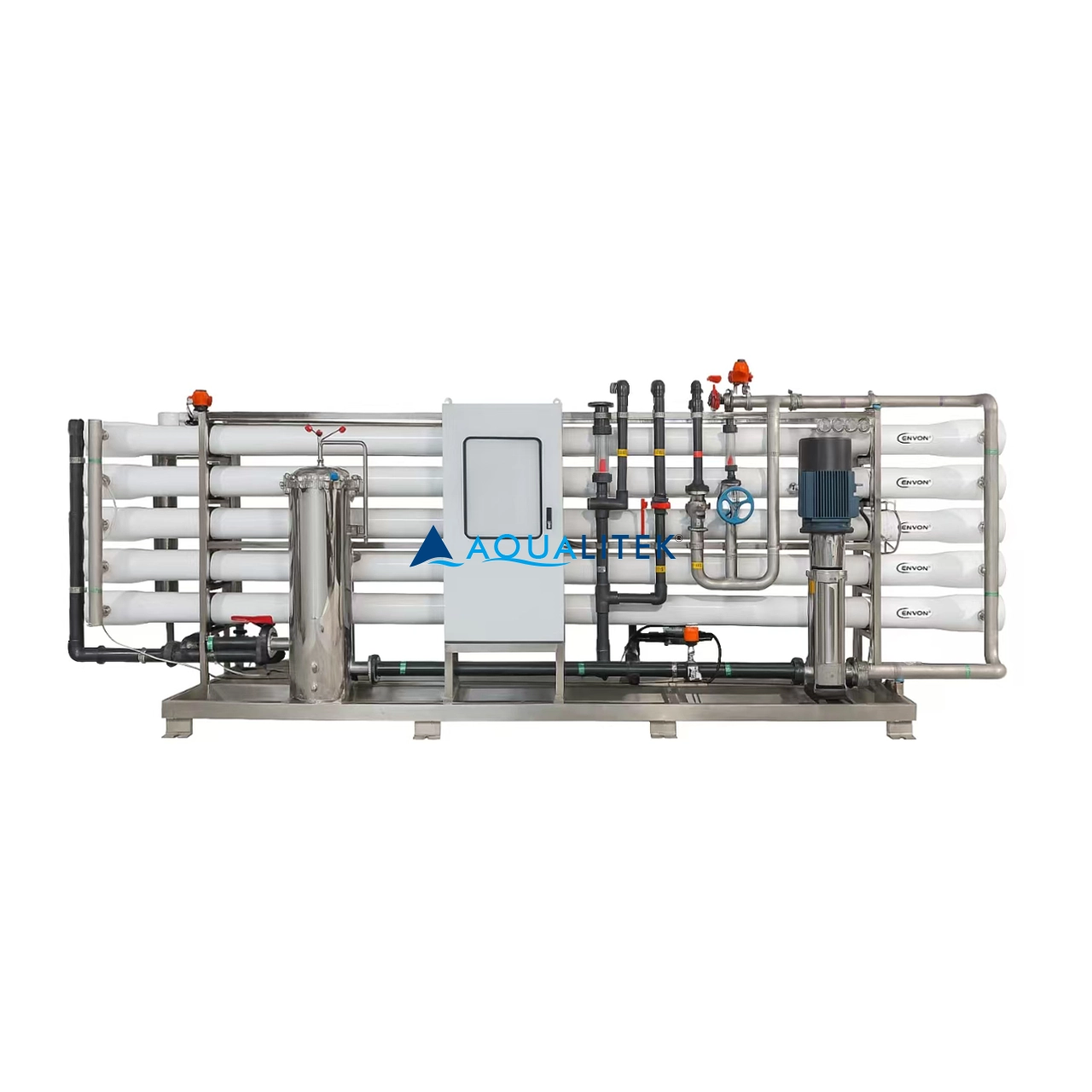

Product overview: Brackish Water Reverse Osmosis (BWRO) Systems BWE Series

BWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for brackish water(higher TDS).The large volumes can help meet your a variety of industrial applications.T hey are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Initial check: symptoms, data collection and safety

Before making any repairs, collect baseline data. For Water Treatment Systems for Well Water using the BWE Series, record: feed pressure, permeate flow, concentrate flow, feed & permeate conductivity or TDS, differential pressures across prefilters and membrane housings, SDI (silt density index), pH, ORP/chlorine, turbidity, and visual inspection (scales, rust, biofilm). Safety first: isolate high-pressure vessels, relieve pressure, and follow lockout/tagout procedures.

Diagnostic checklist

- Feed water analysis: TDS, hardness (Ca2+/Mg2+), iron/manganese, silica, alkalinity, sulfate, chloride, TOC (total organic carbon), ammonia, pH.

- Operating readings: feed pressure (psi/bar), permeate flow (m3/h or GPM), recovery rate (%), conductivity (µS/cm), differential pressure (ΔP) across prefilters and membrane stages.

- Visual/physical: membrane leaks, damaged housings, fouled prefilters, discoloration or odor in tanks/piping.

Common problem 1: Low permeate flow or low recovery

Symptoms: reduced product water flow and/or lower-than-expected recovery on Brackish Water Reverse Osmosis (BWRO) Systems BWE Series. Causes typically include membrane fouling (particulate, biological, organic), scaling (calcium carbonate, barium, strontium, silica), blocked prefilters, or changes in feed TDS or temperature.

Step-by-step resolution

- Check prefilters and replace if DP (differential pressure) exceeds manufacturer spec.

- Measure SDI and turbidity—if SDI > 3 or turbidity > 1 NTU, improve pretreatment (media filters, cartridge filtration, coagulation).

- Inspect feedwater chemistry for scaling ions (hardness, silica). If scaling is likely, reduce recovery, add antiscalant, or soften feed water.

- If biofouling suspected (increased DP with slimy deposits or TOC high), perform chemical clean-in-place (CIP) with alkaline cleaners and biocides as appropriate.

- After cleaning, verify restored flow & recovery and schedule preventive cleaning intervals.

Common problem 2: High permeate conductivity (salt passage)

Symptom: permeate conductivity rising or failing product water quality specifications. Causes include membrane damage, degraded membrane performance from irreversible fouling, feed pressure loss, poor recovery settings, or feed TDS spikes.

Troubleshooting steps

- Confirm sensors are calibrated and plumbing for sample points is correct.

- Check feed pressure and flow—low differential pressure across membranes can increase salt passage; restore design pressures if possible.

- Perform integrity checks: isolate stages to see where salt passage is occurring; rotating individual membrane housings can localize poor elements.

- If membranes show irreversible high salt passage after cleaning, plan element replacement. Document element serial numbers and life history for warranty claims.

Common problem 3: Iron, manganese, and hydrogen sulfide (H2S)

Well water often contains dissolved iron, manganese, and sometimes H2S—these can foul membranes, stain housings, and cause odor. Brackish Water Reverse Osmosis (BWRO) Systems BWE Series perform best with appropriate pretreatment for these species.

Treatment approaches

- Oxidation followed by filtration: Use aeration, chlorination (with dechlorination before RO), or potassium permanganate followed by multimedia filtration to remove oxidized solids.

- Greensand or catalytic media filters for manganese and iron removal.

- For H2S, aeration or chemical oxidation prior to filtration is effective; make sure any residual oxidant is removed before RO membranes (e.g., sodium bisulfite dosing after chlorination).

Common problem 4: Biological fouling (biofouling)

Biofouling causes rapid pressure increases and reduced flux. It is often linked to biodegradable organics, stagnant sections, warm temperatures, or inconsistent chlorination upstream.

Diagnosis and corrective actions

- Indicators: slimy deposits on housings, rapid DP increases, sudden drop in permeate quality after stagnation periods.

- Action: improve upstream disinfection and filtration, maintain continuous flushing if idle, implement scheduled CIP with alkaline/enzymatic cleaners and sanitizers compatible with membranes.

- Consider membrane-compatible biocide dosing and periodic low-dosage chlorination if using chlorine-tolerant membranes is feasible (consult membrane manufacturer).

Common problem 5: Scaling and hardness-related issues

Scaling precursors—calcium carbonate, calcium sulfate, barium, strontium, and silica—crystallize on membrane surfaces when concentration factors rise or pH/temperature favor precipitation. Preventive antiscalant dosing and hardness removal are key.

Prevention and remediation

- Run an Langelier and saturation index for your feed to predict scale risk.

- Use antiscalants specifically designed for brackish RO; follow dosing curves based on feed composition and recovery.

- Where hardness is high, consider softening (ion exchange) ahead of the BWE Series to reduce antiscalant demand and prolong membrane life.

- If scaling occurs, apply an acid-based CIP to remove carbonate scales (follow membrane vendor guidance on concentrations and contact times).

Monitoring and instrumentation best practices for BWRO BWE Series

Good instrumentation speeds diagnosis: install accurate pressure gauges on feed, permeate, and concentrate lines; conductivity meters on feed and permeate; turbidimeters or SDI testing points; and an automated data logger or PLC alarm setpoints for DP, flow and conductivity. Routine trending reveals slow performance degradation before full failure.

Chemical cleaning protocols (CIP) — safe and effective methods

Cleaning choices depend on fouling type. The following table summarizes common fouling types, recommended cleaning chemicals, typical concentrations and safety notes.

| Fouling Type | Chemical(s) | Typical Concentration | Notes/Safety |

|---|---|---|---|

| Organic/Biofouling | Alkaline detergent + enzymes; optionally low-dosage biocide | 0.5–2% w/v alkaline cleaner | Control pH; flush thoroughly; follow MSDS |

| Iron/Manganese deposits | Acid cleaner (citric or sulfamic) | 0.5–1.5% w/v | Corrosive—neutralize and flush; verify compatibility |

| Carbonate scaling | Acid (HCl at low concentration or sulfamic) | 0.5–1.0% w/v | Use acid-compatible seals; don PPE; monitor temperature |

| Silica | High-pH chelants and specialized silica dispersants | Follow manufacturer guidance | Often difficult—may be irreversible at high loads |

Optimization tips: balancing recovery, energy, and longevity

Maximizing recovery increases concentrate TDS and scale risk. For Water Treatment Systems for Well Water using the BWE Series, find the operating point where energy and antiscalant costs do not outweigh savings from higher recovery. Typical approaches:

- Operate at a conservative recovery when feed hardness or silica is high.

- Use energy recovery devices when flows and pressures justify them.

- Reduce frequent starts/stops; maintain steady-state operation to minimize fouling cycles.

- Implement predictive maintenance based on trending, not calendar-only schedules.

Maintenance schedule and spare parts strategy

Establish a maintenance plan: weekly checks (pressures, flows, sensors), monthly checks (prefilter changes, chlorine residual), quarterly or semiannual checks (membrane performance review), and annual thorough inspections and possible CIP. Maintain critical spares: pressure gauges, controller modules, prefilter cartridges, seals and o-rings, and one spare membrane element per rack if downtime costs are high.

When to call technical support or replace membranes

Call your supplier when troubleshooting steps fail to restore acceptable flux or conductivity after proper CIP, or when membranes show physical damage. Replacement is recommended when salt passage is irreversible, cleaning no longer recovers flux, or element integrity is compromised. Keep element serials and cleaning logs—these support warranty claims.

Brand value: Why choose BWE Series for well water BWRO applications

Brackish Water Reverse Osmosis (BWRO) Systems BWE Series combine pre-engineered reliability, eight-inch membrane housings for large capacity, and high recovery performance tailored for brackish and challenging well water. BWE Series advantages include lower installation time (pre-assembled units), predictable performance, simplified maintenance, and cost savings through optimized recovery and low operational demands—making them an excellent option among Water Treatment Systems for Well Water in industrial and municipal applications.

Frequently Asked Questions (FAQ)

Q1: How often should I perform CIP on BWE Series systems?

A1: CIP frequency depends on feed water quality and operational data trends. Typical intervals range from 3 to 12 months. Use trending (flux decline rate, DP rise, permeate conductivity) to set proactive CIP schedules rather than fixed calendar intervals.

Q2: Can BWRO BWE Series handle high-iron well water?

A2: Yes, but pre-treatment is required. Oxidation and filtration (e.g., greensand, multimedia) to remove iron and manganese are essential before RO. Residual oxidants must be neutralized before the membrane.

Q3: What cleaning chemicals are safe for BWE Series membranes?

A3: Use membrane-vendor-recommended alkaline cleaners for organic/biofouling and acids like sulfamic or citric for carbonate/iron scaling. Avoid strong oxidants directly on most polyamide membranes. Always follow manufacturer specs for concentrations and temperatures.

Q4: How do I reduce scaling when feedwater hardness is high?

A4: Options include lowering recovery, using antiscalants with validated dosing, or installing a softening stage (ion exchange) upstream. Select the approach based on cost, water quality, and operational constraints.

Q5: What routine instruments are most valuable?

A5: Reliable pressure gauges, conductivity meters for permeate and feed, and a turbidity or SDI testing point are most valuable for early detection of issues. Data logging and alarms accelerate response time.

Contact us / View Product

If you need help troubleshooting your Brackish Water Reverse Osmosis (BWRO) Systems BWE Series, or want to evaluate Water Treatment Systems for Well Water for your project, contact our technical team for diagnostics, spare parts, and on-site support. Visit the BWE Series product page or contact sales for a custom solution and quotation.

Authoritative references

- U.S. Environmental Protection Agency (EPA) — Drinking Water Treatment & Reverse Osmosis Overview: https://www.epa.gov/

- World Health Organization (WHO) — Water Quality and Treatment: https://www.who.int/

- Wikipedia — Reverse Osmosis: https://en.wikipedia.org/wiki/Reverse_osmosis

- U.S. Geological Survey (USGS) — Groundwater Quality: https://www.usgs.gov/

- Water Quality Association (WQA) — Technical resources: https://www.wqa.org/

References above are general knowledge repositories; consult membrane manufacturer documentation for BWE Series-specific cleaning chemistries and warranty conditions.

How 4TPH Industrial RO System Improves Plant Water Quality

Maintenance Checklist for Your Water Purification System: Practical Guide for Reliable Performance

Performance Testing and QA for Stainless Micron Filter Housings

Why Choose a 30TPH Industrial Reverse Osmosis (RO) System

Ion Exchange Water Treatment Systems

Are mixed bed systems better than two-bed systems?

Mixed bed polishers are used for final polishing after RO or two-bed deionization to achieve ultra-pure water.

Solutions

What is the difference between Reverse Osmosis (RO), Ultrafiltration (UF), and Nanofiltration (NF)?

1. Reverse Osmosis (RO): Removes up to 99.9% of contaminants, including salts, bacteria, viruses, and heavy metals.

2. Ultrafiltration (UF): Uses a membrane filtration process to remove bacteria and particles, while retaining essential minerals.

3. Nanofiltration (NF): Falls between RO and UF, removing some salts and organic compounds while allowing certain minerals to pass through.

Water Filters

What is the expected lifespan of a water filter?

Cartridge filters generally last 1–3 months. Media filters require periodic backwashing and media replacement every 1–2 years, depending on usage.

FAQ-aqualitek

Can I use AQT’s water treatment systems for seawater desalination?

Yes! We provide seawater desalination systems using advanced reverse osmosis (RO) technology, specifically designed to convert seawater into fresh, drinkable water. These systems are ideal for coastal communities, marine applications, and industrial desalination projects.

Does AQT provide technical support and after-sales service?

Yes! We offer comprehensive technical support, including installation guidance, troubleshooting, spare parts supply, and ongoing maintenance assistance. Our after-sales team is available to ensure your water treatment system operates efficiently.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

30TPH Industrial Reverse Osmosis (RO) System

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

500LPH Panel Mounted Reverse Osmosis Water Purification System

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

Electrodeionization Systems to Get UltraPure Water

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo