How BWRO BWE Series Treats High-TDS Well Water Effectively

- How BWRO BWE Series Treats High-TDS Well Water Effectively

- Why specialized Water Treatment Systems for Well Water are essential

- Understanding high-TDS well water and treatment goals

- What the Brackish Water Reverse Osmosis BWE Series delivers

- Key components and how they work in Water Treatment Systems for Well Water

- Performance metrics: rejection, recovery, and operating parameters

- Pretreatment essentials for high-TDS well water

- Installation, operation, and maintenance best practices

- Applications and typical results for Water Treatment Systems for Well Water

- Cost considerations and return on investment

- Comparing BWRO BWE Series to alternative technologies

- Brand advantages of choosing the BWE Series in real projects

- Frequently Asked Questions (FAQ)

- Q: What feed TDS range can the BWE Series handle?

- Q: Do I always need antiscalant and softening before BWRO?

- Q: How often do membranes need replacement?

- Q: How is brine or concentrate managed?

- Q: Can BWE Series systems be automated and remotely monitored?

- Q: What product water quality can I expect?

- Contact and next steps

- References and authoritative resources

How BWRO BWE Series Treats High-TDS Well Water Effectively

Why specialized Water Treatment Systems for Well Water are essential

Many private and commercial wells contain high levels of total dissolved solids, or TDS. High-TDS well water can cause scaling, taste and odor problems, poor process performance in industry, and even exceed secondary drinking water recommendations. For industrial and larger commercial needs, robust Water Treatment Systems for Well Water must reliably reduce dissolved salts and contaminants while minimizing waste and operating costs. Brackish Water Reverse Osmosis, or BWRO, is a proven technology for these conditions. This article explains how the Brackish Water Reverse Osmosis (BWRO) Systems BWE Series meets high-TDS challenges and practical considerations for deploying them. Understanding how the BWRO BWE series treats high-TDS well water effectively is the foundation of system selection, but water quality varies widely. To design a reliable solution, it’s essential to first identify the common well water contaminants removed by the BWRO BWE series.

Understanding high-TDS well water and treatment goals

High-TDS well water typically contains elevated concentrations of dissolved minerals such as sodium, calcium, magnesium, chloride, sulfate, and bicarbonate. The specific treatment goals vary by application: for potable use, TDS is often targeted to be below 500 mg/L to meet secondary EPA guidance; for boiler feed or industrial process water, even lower limits may be required to prevent scaling and corrosion. When selecting Water Treatment Systems for Well Water, key objectives include:

- Reducing TDS and ionic contaminants to required product water quality

- Maximizing recovery to reduce wastewater and operating costs

- Controlling scaling and fouling via effective pretreatment

- Providing reliable, low-maintenance operation for long membrane life

What the Brackish Water Reverse Osmosis BWE Series delivers

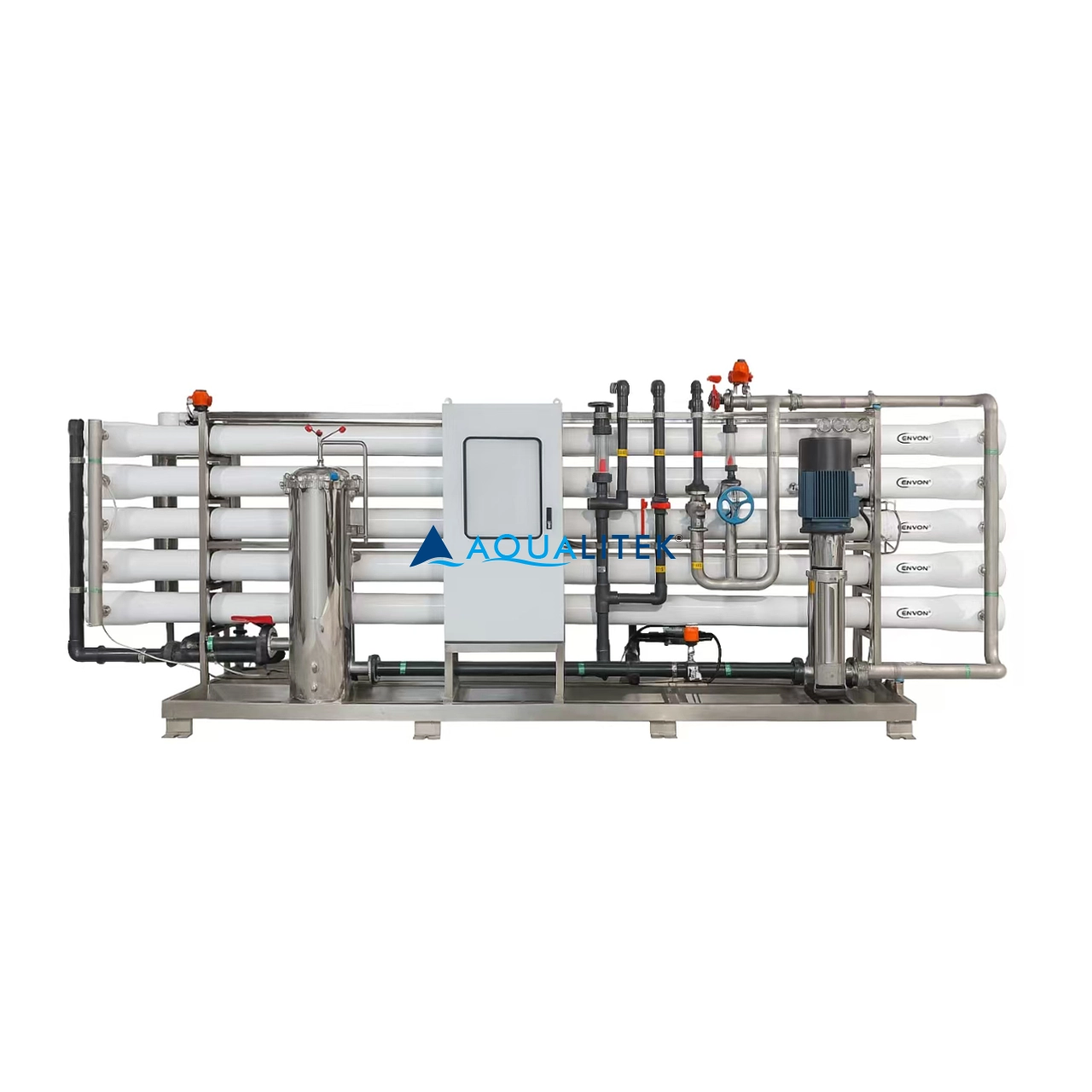

BWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for brackish water(higher TDS).The large volumes can help meet your a variety of industrial applications.T hey are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

The BWE Series combines BWRO membranes, optimized pressure staging, and integrated controls to treat brackish well water feeds. Because the units are pre-engineered and factory assembled, they reduce installation time and engineering cost while delivering predictable performance. Key built-in advantages include modular 8-inch membrane housings for higher element capacity, high recovery configuration options, and compatibility with standard chemical dosing and filtration components.

Key components and how they work in Water Treatment Systems for Well Water

A complete BWRO solution consists of several subsystems. For high-TDS well water, each performs an essential role:

- Pretreatment - Sediment filtration, multimedia filters, and activated carbon remove turbidity, particulates, and organics that foul membranes. Iron and manganese removal systems are often required since these metals can clog and foul RO membranes.

- Water conditioning - pH adjustment and antiscalant dosing reduce the risk of scaling on membrane surfaces when treating high-mineral feeds. For very hard or sulfate-rich waters, softening or stronger antiscalant strategies may be needed.

- High-pressure pump and feed distribution - Delivers feedwater at the required pressure to achieve the designed recovery and permeate quality.

- RO membrane trains - The BWE Series uses brackish RO membranes configured in 8-inch housings to provide large membrane area and high throughput for brackish feeds. Membrane selection and staging determine rejection and recovery characteristics.

- Control and monitoring - Conductivity meters, pressure gauges, flow meters, and automated control valves maintain performance, protect membranes, and allow for remote monitoring in many setups.

Performance metrics: rejection, recovery, and operating parameters

When evaluating Water Treatment Systems for Well Water, three performance metrics matter most: salt rejection (percent reduction of TDS), system recovery (percent of feed converted to permeate), and specific energy consumption. Typical ranges for BWRO systems treating brackish well water are shown below.

| Parameter | Typical BWRO BWE Series Range | Notes |

|---|---|---|

| Feed TDS | 500 - 8,000 mg/L | Effective across broad brackish range; pretreatment needs increase with higher TDS |

| Permeate TDS | < 100 - 500 mg/L | Depends on feed TDS and target recovery; blending and polishing may be used |

| Salt rejection | 95 - 99% | Typical for modern brackish RO membranes |

| System recovery | 65 - 85% | Higher recovery saves water but increases scaling risk; antiscalant and staging control recovery |

| Energy use | 0.5 - 2.0 kWh/m3 | Varies with feed TDS, recovery, and pump efficiency |

| Typical membrane cleaning | Every 3 - 12 months | Dependent on fouling rate and pretreatment quality |

Pretreatment essentials for high-TDS well water

High mineral content increases the risk of scaling on RO membranes. Effective pretreatment prevents irreversible fouling and extends membrane life. Key pretreatment measures include:

- Iron and manganese removal - Oxidation and filtration or chemical sequestration are commonly used for wells with these metals.

- Particulate filtration - Multi-stage cartridge or sand filtration reduces turbidity and protects membranes from abrasion and clogging.

- Antiscalant dosing - Proper antiscalant selection and dosing allow higher recovery while preventing mineral scale formation for feeds with high hardness or sulfate.

- pH control - Adjusts solubility equilibria to reduce scaling potential and improve membrane performance.

Neglecting pretreatment is one of the most common causes of premature membrane failure in Water Treatment Systems for Well Water. The BWE Series is compatible with a wide range of pretreatment options and can be delivered as a package including these systems.

Installation, operation, and maintenance best practices

Because BWE Series units are pre-assembled, installation time is shorter than custom-built systems. Still, following best practices ensures reliable long-term operation:

- Verify feed water characterization with comprehensive lab testing before sizing the system.

- Install adequate pretreatment sized for peak flows and water quality variability.

- Use instrumentation to monitor feed and permeate conductivity, differential pressure across filters, and flow rates.

- Implement a cleaning and chemical maintenance schedule based on measured performance decline rather than fixed intervals.

- Plan for brine disposal or beneficial reuse in compliance with local regulations.

Applications and typical results for Water Treatment Systems for Well Water

The BWE Series is suitable for municipal well augmentation, industrial process water, boiler feedwater, irrigation where salinity must be controlled, and commercial potable supply with post-treatment blending. Typical outcomes depend on feed TDS and treatment goals, but operators commonly achieve permeate suitable for many industrial uses and reduced TDS approaching potable thresholds when paired with post-treatment polishing where required.

Cost considerations and return on investment

When comparing Water Treatment Systems for Well Water, consider both capital cost and lifecycle operating expenses. BWRO systems like the BWE Series typically offer:

- Lower chemical costs than ion exchange for high salt loads

- Reduced waste volume with higher recovery configurations

- Lower labor and maintenance overhead when delivered as pre-assembled modular units

To estimate ROI, include lifespan of membranes, frequency of cleaning, energy costs, and local disposal costs for concentrate. In many industrial settings, RO-based solutions provide payback in a few years compared with recurring costs of alternative technologies.

Comparing BWRO BWE Series to alternative technologies

Reverse osmosis is not the only option for reducing TDS, but it is often the most flexible for moderate to high brackish concentrations. A high-level comparison:

| Technology | Best use cases | Advantages | Limitations |

|---|---|---|---|

| BWRO BWE Series | Brackish well water, industrial feed, potable blending | High salt removal, modular, good recovery, scalable | Requires pretreatment and brine management |

| Ion exchange | Selective ion removal, softening | Effective for hardness, predictable effluent | High chemical use for regeneration with high TDS; limited for mixed salts |

| Electrodialysis | Salinity reduction for specific ionic compositions | Good for high recovery and certain salts | Higher capital cost; complex operation |

Brand advantages of choosing the BWE Series in real projects

When selecting Water Treatment Systems for Well Water, the BWE Series stands out for several reasons:

- Pre-engineered and pre-assembled - Reduces on-site engineering and installation time, lowering project risk and soft costs.

- 8-inch membrane housings - Provide higher membrane area per vessel and efficient footprint for large flows.

- High recovery options - Save water and reduce discharge volumes when paired with proper antiscalant and staging.

- Low maintenance and accessible service - Factory assembly, standardized components, and clear maintenance procedures help reduce downtime.

- Scalable and customizable - Suitable for single-package installations up to multi-train plants to meet growing demand.

Together, these advantages translate to predictable performance, lower lifetime cost, and simplified project execution compared with bespoke solutions.

Frequently Asked Questions (FAQ)

Q: What feed TDS range can the BWE Series handle?

A: The BWE Series is designed for brackish water and typically treats feeds from around 500 mg/L up to several thousand mg/L of TDS. Exact feed limits depend on required permeate quality and recovery; consult with a water speciations engineer for feeds above 5,000 mg/L.

Q: Do I always need antiscalant and softening before BWRO?

A: Antiscalant dosing is recommended for most high-TDS feeds to enable higher recovery while preventing scale. In cases of very high hardness, a water softener or specialized pretreatment may be required to protect membranes.

Q: How often do membranes need replacement?

A: Membrane life varies with feed conditions and maintenance. With good pretreatment and proper cleaning, membranes often last 3 to 7 years, and in some cases longer. Regular monitoring and cleaning extend service life.

Q: How is brine or concentrate managed?

A: Options include discharge to sewer where permitted, deep well injection, evaporation ponds, or beneficial reuse in compatible process applications. Local regulations and environmental considerations determine the best approach.

Q: Can BWE Series systems be automated and remotely monitored?

A: Yes. The BWE Series supports modern control and monitoring options including PLC control, remote telemetry, and automated alarms for conductivity, pressure, and flow.

Q: What product water quality can I expect?

A: Permeate quality depends on feed TDS and recovery. Typical permeate TDS falls under 100 to 500 mg/L for many brackish feeds. When potable standards are required, post-treatment polishing and blending may be used to meet specific regulatory limits.

Contact and next steps

If you are evaluating Water Treatment Systems for Well Water, our team can help with feedwater analysis, system sizing, and a customized proposal for the BWRO BWE Series. Request a quote or technical consultation:

Contact our sales team | View BWE Series product page

References and authoritative resources

- EPA - Secondary Drinking Water Standards and Guidance

- USGS - Total Dissolved Solids (TDS)

- Water Quality Association - Reverse Osmosis

- NSF - What is Reverse Osmosis

For a tailored assessment, contact us with your well water test report so we can recommend the optimal BWE Series configuration and pretreatment package for your site.

Smart Water Purification Systems: Features and Benefits

Why Choose a 30TPH Industrial Reverse Osmosis (RO) System

Top 10 water treatment equipment Manufacturers and Supplier Brands

How Much Does a Water Purification System Cost?

FAQ-aqualitek

Can I use AQT’s water treatment systems for seawater desalination?

Yes! We provide seawater desalination systems using advanced reverse osmosis (RO) technology, specifically designed to convert seawater into fresh, drinkable water. These systems are ideal for coastal communities, marine applications, and industrial desalination projects.

How do I choose the right water treatment system for my needs?

The choice depends on factors such as water quality, application, flow rate, and purification requirements. Our team of experts can analyze your water source and recommend the most suitable solution for residential, commercial, or industrial applications.

What industries does AQT serve?

We provide water treatment solutions for a wide range of industries, including:

Industrial Manufacturing – Process water treatment, cooling water, and boiler feed.

Hospitality & Commercial – Hotels, restaurants, and office buildings.

Residential Applications – Drinking water purification and softening.

Healthcare & Pharmaceuticals – Ultra-pure water for laboratories and hospitals.

Municipal & Public Utilities – Water supply and wastewater treatment.

Food & Beverage Processing – Filtration for beverage production and food safety.

Solutions

Can AQT provide custom water treatment solutions?

Yes! We specialize in OEM/ODM water treatment solutions and can design custom filtration systems tailored to your business, industry, or brand requirements. Our team can assist with system design, branding, private labeling, and technical support.

Water Filters

Are your filters suitable for seawater or chemical-heavy applications?

Yes, we offer FRP and stainless steel housings resistant to corrosion and suitable for marine or aggressive chemical environments.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

30TPH Industrial Reverse Osmosis (RO) System

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

500LPH Panel Mounted Reverse Osmosis Water Purification System

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

Electrodeionization Systems to Get UltraPure Water

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo