Reverse Osmosis for Well Water: When and Why to Use It

- How to Decide if Your Well Needs Advanced Filtration

- Why testing matters for Water Treatment Systems for Well Water

- When reverse osmosis becomes necessary for well owners

- How Reverse Osmosis Works and What It Removes in Well Water

- Principles of RO relevant to Water Treatment Systems for Well Water

- Contaminant removal performance for well water

- Assessing Suitability: When RO is Not the Best Choice

- Limitations and cases where other Water Treatment Systems for Well Water are preferred

- Design, Sizing, Pretreatment and Operating Costs

- Key design considerations for residential and commercial RO systems

- Cost and maintenance expectations for Water Treatment Systems for Well Water

- Comparative Guidance: Choosing Between RO and Other Systems

- Decision matrix for selecting Water Treatment Systems for Well Water

- Installation, Commissioning and Long-Term Performance

- Best practices to ensure reliable RO performance

- Aqualitek: Partnering to Deliver Water Treatment Systems for Well Water

- Why consider Aqualitek for RO and other well water solutions

- Aqualitek product strengths and core offerings

- How Aqualitek differentiates in the market

- Practical Next Steps for Well Owners Considering RO

- Action checklist for evaluating and implementing RO

- Frequently Asked Questions (FAQ)

- 1. Will RO remove bacteria and viruses from well water?

- 2. How often should RO membranes be replaced for well water applications?

- 3. Can RO handle high hardness well water?

- 4. How much water does an RO system waste?

- 5. Is whole-house RO practical for a typical home on well water?

- 6. How should I dispose of RO concentrate if I have high contaminants like arsenic or nitrate?

- Contact and Product Inquiry

- References and Further Reading

How to Decide if Your Well Needs Advanced Filtration

Why testing matters for Water Treatment Systems for Well Water

Well owners often assume 'clear water equals safe water', but aesthetic clarity does not guarantee the absence of dissolved contaminants such as nitrate, arsenic, or total dissolved solids (TDS). The first step in evaluating any Water Treatment Systems for Well Water is a comprehensive water test. Tests should include basic parameters (pH, hardness, iron, manganese), microbiological tests (total coliforms and E. coli), and targeted chemical tests (nitrate, arsenic, lead, sulfate, TDS), guided by local geology and land use. Regular testing provides the data needed to determine whether reverse osmosis is appropriate, or whether pretreatment and alternative systems are better fits.

When reverse osmosis becomes necessary for well owners

Reverse osmosis is well suited when dissolved inorganic contaminants or high TDS are the primary problems. Key triggers that suggest RO may be required include: nitrate above the EPA Maximum Contaminant Level (MCL) of 10 mg/L as N, arsenic approaching or exceeding 10 µg/L, sodium or chloride levels causing taste or corrosion problems, persistent high TDS (>500 mg/L) affecting appliances, and water with multiple dissolved contaminants where a single-point, high-removal technology is preferred. RO is also effective where households need point-of-use high-quality drinking and cooking water and where whole-house softening is not desired.

How Reverse Osmosis Works and What It Removes in Well Water

Principles of RO relevant to Water Treatment Systems for Well Water

Reverse osmosis forces water through a semipermeable membrane under pressure, rejecting a high percentage of dissolved salts, many organic molecules, and most particles larger than the membrane pores. Typical residential RO systems use a membrane with nominal pore sizes around 0.0001 microns, enabling removal of 90-99% of many dissolved ions. However, RO does not provide consistent microbiological disinfection unless combined with pre- or post-treatment, since membrane breach, feed water pressure fluctuations, or improper maintenance can allow bacterial passage or regrowth in storage tanks.

Contaminant removal performance for well water

RO excels at removing dissolved inorganic contaminants. Table 1 summarizes typical removal ranges for RO and compares RO with other common Water Treatment Systems for Well Water.

| Treatment Technology | Typical removal: Nitrate | Typical removal: Arsenic | Typical removal: Bacteria | Typical removal: Hardness (Ca/Mg) | Typical removal: TDS |

|---|---|---|---|---|---|

| Reverse Osmosis (Point-of-Use) | 90-99% | 85-99% (with proper pre-treatment for AsIII) | Variable; not a standalone disinfection step | Partial (depends on membrane and recovery) | 70-99% |

| Ion Exchange (Water Softeners) | Low | Low | None | 85-99% (hardness removed) | Little effect on TDS |

| Activated Carbon | Low | Low | None | None | Little effect |

| UV Disinfection | None | None | High (99.99% if dose adequate) | None | None |

Sources for removal ranges include EPA, WQA, and manufacturer performance data. Removal efficiency depends on feed water chemistry, membrane type, temperature, pressure, and pretreatment strategies.

Assessing Suitability: When RO is Not the Best Choice

Limitations and cases where other Water Treatment Systems for Well Water are preferred

Reverse osmosis is not always the optimal solution. Situations where RO may not be appropriate include: microbiologically contaminated wells without reliable disinfection; very high iron or manganese without pretreatment (which will foul membranes quickly); high hardness without pretreatment (scale reduces membrane life); and whole-house demands where RO point-of-use capacity cannot economically meet flow needs. In many cases, combining technologies yields the best outcome: UV or chlorination for bacteria, greensand or oxidation filtration for iron and manganese, ion exchange for hardness, and RO as a final polishing step for drinking water.

Design, Sizing, Pretreatment and Operating Costs

Key design considerations for residential and commercial RO systems

Designing a successful RO solution for well water must start with water quality. Typical considerations include TDS and specific contaminants, iron and manganese levels, hardness, turbidity, and bacterial test results. Pretreatment commonly includes sediment filtration, activated carbon for organics/chlorine removal (important for membrane longevity), water softening, and oxidizing filters for iron/arsenic speciation control. For systems treating water with significant arsenic in its reduced form (AsIII), an oxidation step (e.g., chlorine, permanganate) or specific adsorption is necessary before RO to maximize arsenic rejection.

Cost and maintenance expectations for Water Treatment Systems for Well Water

Costs vary widely. Typical residential under-sink RO systems cost between 300 and 2,000 USD installed depending on capacity and pretreatment requirements. Operating costs include periodic filter and membrane replacement, electricity for booster pumps (if used), and increased water use: conventional RO rejects 15-50% of feed water as concentrate depending on recovery rate. Commercial and industrial RO systems for well water scale up in capital cost but can be designed for higher recovery and integrated concentrate management. Budget conservatively for annual maintenance equal to 5-15% of capital cost for small systems, higher if pretreatment is poorly matched.

Comparative Guidance: Choosing Between RO and Other Systems

Decision matrix for selecting Water Treatment Systems for Well Water

Use the following guidance when choosing a system: if microbiological contamination is present, prioritize disinfection (UV/chlorination) and re-test before installing RO; if dissolved inorganic contaminants like nitrate or arsenic are above health thresholds, RO is a strong choice; if hardness is the only issue and dissolved solids are low, ion exchange softeners are more economical; for iron/manganese, remove and stabilize those first to prevent downstream fouling. Always evaluate lifecycle cost, not just upfront price.

Installation, Commissioning and Long-Term Performance

Best practices to ensure reliable RO performance

Follow these operational best practices for longevity and performance: ensure effective pretreatment to protect membranes; install pressure and flow monitoring; include a low-pressure lockout to prevent membrane damage; schedule periodic sanitization and membrane integrity checks; replace carbon and sediment filters at recommended intervals; and monitor permeate quality by measuring TDS or conductivity. Record-keeping of maintenance, pressure differentials, and water quality results helps detect performance decline early.

Aqualitek: Partnering to Deliver Water Treatment Systems for Well Water

Why consider Aqualitek for RO and other well water solutions

Aqualitek Water Treatment Technologies Co., Ltd. (AQT), headquartered in Guangzhou, China, is a leading manufacturer and supplier of advanced water treatment systems and high-quality component parts. AQT specializes in delivering customized solutions for residential, commercial, and industrial applications, meeting diverse water purification needs worldwide. Their capabilities include engineering bespoke pretreatment trains, membrane systems, and integrated control platforms optimized for well water chemistry.

Aqualitek product strengths and core offerings

Aqualitek's product portfolio focuses on membrane systems, water filtering systems, ion exchange systems, and customized water purification systems. Key advantages are strong engineering support, modular designs for easier commissioning, and scalable manufacturing to support both single-family installations and larger community or industrial projects. Aqualitek emphasizes efficiency, reliability, and maintainability, and supports partners with technical sampling programs, pilot testing, and aftermarket parts supply.

How Aqualitek differentiates in the market

Aqualitek differentiates through rapid customization, vertical manufacturing control of critical components, and applied engineering expertise for complex well-water challenges such as arsenic speciation, high iron feeds, or brackish well sources. For purchasers seeking a turnkey supplier capable of delivering pretreatment, RO membrane skids, control systems, and long-term parts support, Aqualitek offers a competitive package built on manufacturing excellence and global logistics.

Practical Next Steps for Well Owners Considering RO

Action checklist for evaluating and implementing RO

- Obtain a comprehensive water test from a certified lab including microbiological and chemical panels appropriate to local geology.

- Consult a qualified water treatment professional or supplier to review test results and recommend a treatment train combining pretreatment, disinfection, and RO if needed.

- Review lifecycle costs, water recovery, and concentrate disposal options for chosen RO systems.

- Plan for scheduled maintenance and monitoring, especially membrane replacement and microbiological surveillance.

- Consider pilot testing for challenging feeds prior to full-scale installation.

Frequently Asked Questions (FAQ)

1. Will RO remove bacteria and viruses from well water?

RO membranes can reject many microorganisms due to very small pore sizes, but RO is not a certified disinfection method on its own. A breach, membrane fouling, or storage tank contamination can allow microbial presence. For safety, combine RO with a verified disinfection step such as UV or chlorination and maintain routine testing.

2. How often should RO membranes be replaced for well water applications?

Membrane lifespan varies widely by feed water quality and pretreatment. In well-maintained systems with appropriate pretreatment, membranes often last 2-5 years. High iron, manganese, or biological fouling can shorten this significantly. Monitor permeate TDS increase and pressure drop across the membrane to decide replacement timing.

3. Can RO handle high hardness well water?

RO reduces hardness partially but is sensitive to scaling. For high hardness feed, install a water softener or antiscalant pretreatment to protect membranes and maintain recovery rates.

4. How much water does an RO system waste?

Conventional RO rejects between 15-50% as concentrate (waste), depending on system recovery and configuration. High-recovery systems and reuse strategies reduce waste but may increase capital and pretreatment requirements.

5. Is whole-house RO practical for a typical home on well water?

Whole-house RO is uncommon for typical homes due to high cost, large space requirements, and concentrate management. Most homeowners choose point-of-use RO for drinking and cooking and use whole-house pretreatment (softening, iron removal, UV) for other household needs.

6. How should I dispose of RO concentrate if I have high contaminants like arsenic or nitrate?

Concentrate disposal must comply with local environmental regulations. Options include dilution to sanitary sewers where permitted, controlled discharge to permitted disposal systems, or collection and transport for disposal when contaminants exceed discharge limits. Consult local authorities and environmental engineers for compliant solutions.

Contact and Product Inquiry

If you are evaluating Water Treatment Systems for Well Water and want tailored guidance or pilot testing for reverse osmosis solutions, contact Aqualitek for engineering consultation, sample analysis, and product options. Visit Aqualitek to review membrane systems, water filtering systems, ion exchange systems, and customized purification systems suited to your well water challenges. Request a quote or technical datasheet to start a site-specific assessment.

References and Further Reading

- EPA, Private Drinking Water Wells. https://www.epa.gov/privatewells. Accessed 2025-12-09.

- CDC, Private Well Safety. https://www.cdc.gov/healthywater/drinking/private/index.. Accessed 2025-12-09.

- USGS, Groundwater Information. https://www.usgs.gov/special-topics/water-science-school/science/groundwater-101. Accessed 2025-12-09.

- Water Quality Association, Reverse Osmosis. https://www.wqa.org/learn-about-wqa/water-treatment-technologies/reverse-osmosis. Accessed 2025-12-09.

- EPA, National Primary Drinking Water Regulations. https://www.epa.gov/ground-water-and-drinking-water/national-primary-drinking-water-regulations. Accessed 2025-12-09.

- World Health Organization, Drinking-water. https://www.who.int/news-room/fact-sheets/detail/drinking-water. Accessed 2025-12-09.

Operational Costs and ROI of Commercial Reverse Osmosis Systems

Maintenance Guide for BWRO BWE Series in Well Water Applications

Signs Your Water Purification System Needs Repair

Common Contaminants in Well Water and Treatment Options

Water Filters

Are your filters suitable for seawater or chemical-heavy applications?

Yes, we offer FRP and stainless steel housings resistant to corrosion and suitable for marine or aggressive chemical environments.

Can I automate the filter cleaning process?

Absolutely. Our automatic backwash filters come with timer-based or differential pressure-triggered controls.

How do I choose between a media filter and a micron filter?

Media filters are ideal for high-volume solids removal and can be backwashed. Micron filters offer precise filtration for fine particles and are best for polishing applications.

FAQ-aqualitek

How often should I replace filters and membranes?

Filter and membrane lifespan depends on water quality, usage, and system type. General guidelines:

1. Sediment & Carbon Filters: Replace every 6–12 months.

2. RO Membranes: Replace every 2–3 years, depending on water conditions.

3. UF/NF Membranes: Replace every 1–2 years.

Regular maintenance ensures optimal performance and water quality.

Solutions

How often should I replace filters and membranes?

Filter and membrane lifespan depends on water quality, usage, and system type. General guidelines:

1. Sediment & Carbon Filters: Replace every 6–12 months.

2. RO Membranes: Replace every 2–3 years, depending on water conditions.

3. UF/NF Membranes: Replace every 1–2 years.

Regular maintenance ensures optimal performance and water quality.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

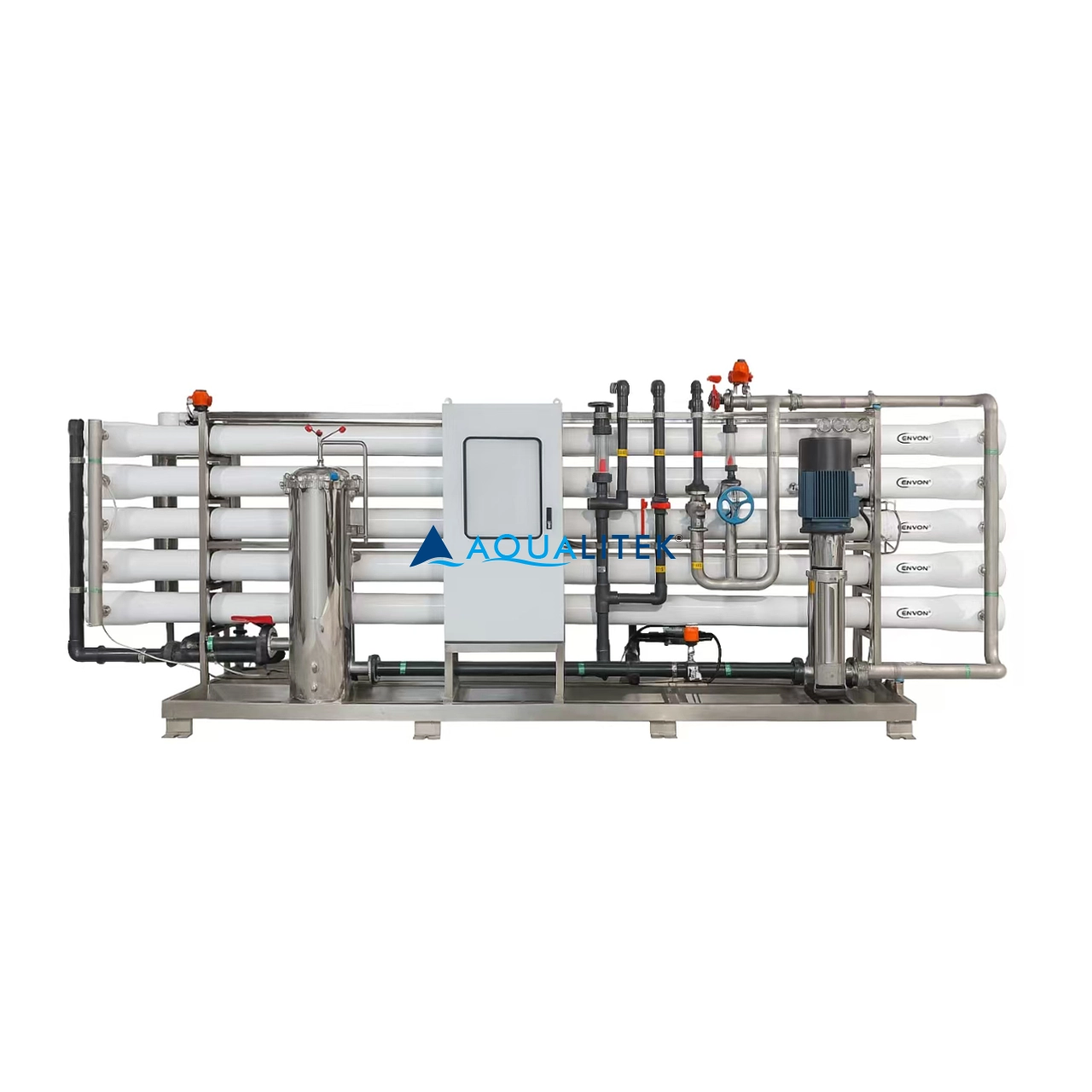

30TPH Industrial Reverse Osmosis (RO) System

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

500LPH Panel Mounted Reverse Osmosis Water Purification System

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

Electrodeionization Systems to Get UltraPure Water

Electrodeionization (EDI) system is an advanced water purification technology that combines ion exchange and electrochemical processes to produce ultra-pure water. Unlike traditional deionization methods, which rely on chemical regeneration, EDI utilizes electric fields to drive the movement of ions through ion-exchange membranes, effectively removing dissolved salts and other ionic contaminants.

This process is continuous and does not require the use of chemicals for regeneration, making it an environmentally friendly and cost-effective solution for producing high-quality deionized water. EDI systems are widely used in applications requiring ultrapure water, such as in the pharmaceutical, semiconductor, power generation, and biotechnology industries, as well as for laboratory use.

By offering high-purity water without the need for chemical regeneration, EDI systems provide a sustainable, efficient, and reliable alternative to traditional deionization methods, making them an ideal choice for industries where water quality and process control are critical.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo