Procurement Checklist: Installing an Industrial RO System

- Pre-procurement: Define Requirements and Constraints

- 1. Define water quality goals and application-specific needs

- 2. Identify production capacity and redundancy requirements

- 3. Regulatory and quality standards

- Site Assessment and Civil/Mechanical Preparation

- 1. Physical footprint, structural support, and placement

- 2. Utilities: water, power, and drains

- 3. Piping, valving, and instrumentation locations

- Technical Selection: System Components and Pretreatment

- 1. Pretreatment options and rationale

- 2. Membrane types and recovery strategies

- 3. Controls, automation, and monitoring

- Procurement, Commissioning and Lifecycle Considerations

- 1. Procurement checklist and contractual items

- 2. Commissioning & performance testing

- 3. Operation, maintenance and lifecycle cost planning

- Brand Fit: Why AQUALITEK for Industrial RO Projects

- 1. Product focus and suitability

- 2. Technical support, warranty and training

- 3. Sustainability and compliance advantages

- FAQ — Common Questions About Procuring and Installing an Industrial RO System

- Q: How do I know if a 4TPH RO system is the right size?

- Q: What pretreatment is absolutely required for RO membranes?

- Q: What are realistic operating costs for an industrial RO system?

- Q: How long do RO membranes last?

- Q: Where can I find technical references for reverse osmosis?

- Next Steps — Contact and Product Information

This procurement checklist helps organizations plan and execute the purchase and installation of an industrial RO system with confidence. It covers the critical technical, site, regulatory, and commercial factors you must assess to achieve reliable, high-quality output water, avoid hidden costs, and shorten time-to-production. The guidance is practical for water reuse, manufacturing rinsing, and processes requiring tight conductivity/TOC control. Semantic keywords naturally referenced in this article include: industrial reverse osmosis system, industrial RO plant, commercial RO unit, membrane filtration, high-recovery RO, brine management, pretreatment, and CIP (clean-in-place).

Pre-procurement: Define Requirements and Constraints

1. Define water quality goals and application-specific needs

Start by documenting the target feed and product water parameters: total dissolved solids (TDS), conductivity, turbidity, SDI, iron, manganese, hardness (calcium and magnesium), silica, TOC, and any specific organics or ionic contaminants. For example, electronic component cleaning typically requires very low conductivity and low particulate counts. Testing incoming water for at least 3–7 days gives a representative baseline—seasonal variations (rainfall, municipal changes) must be considered. Use these inputs to set design targets such as permeate conductivity < 5 µS/cm, recovery rates, and allowable brine composition.

2. Identify production capacity and redundancy requirements

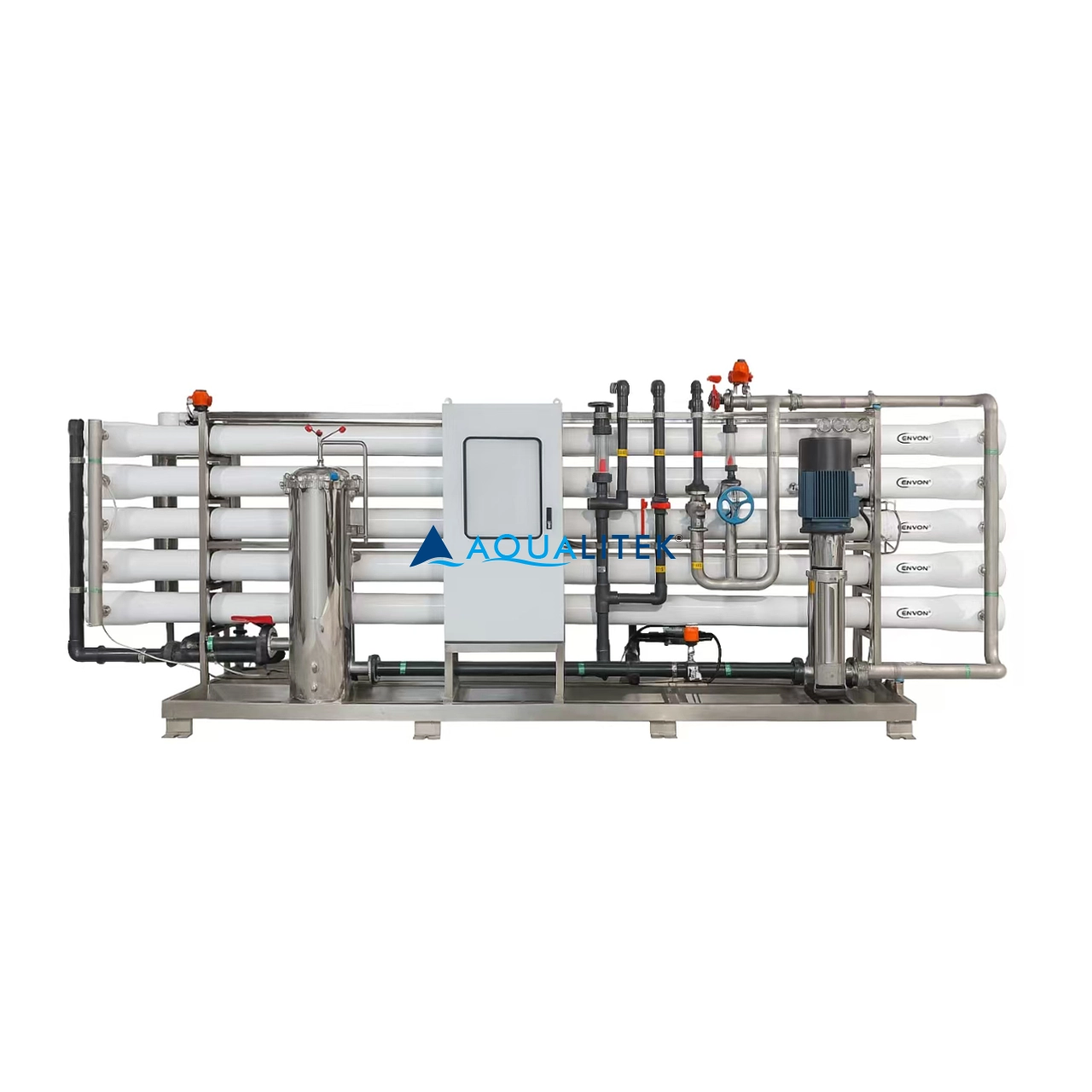

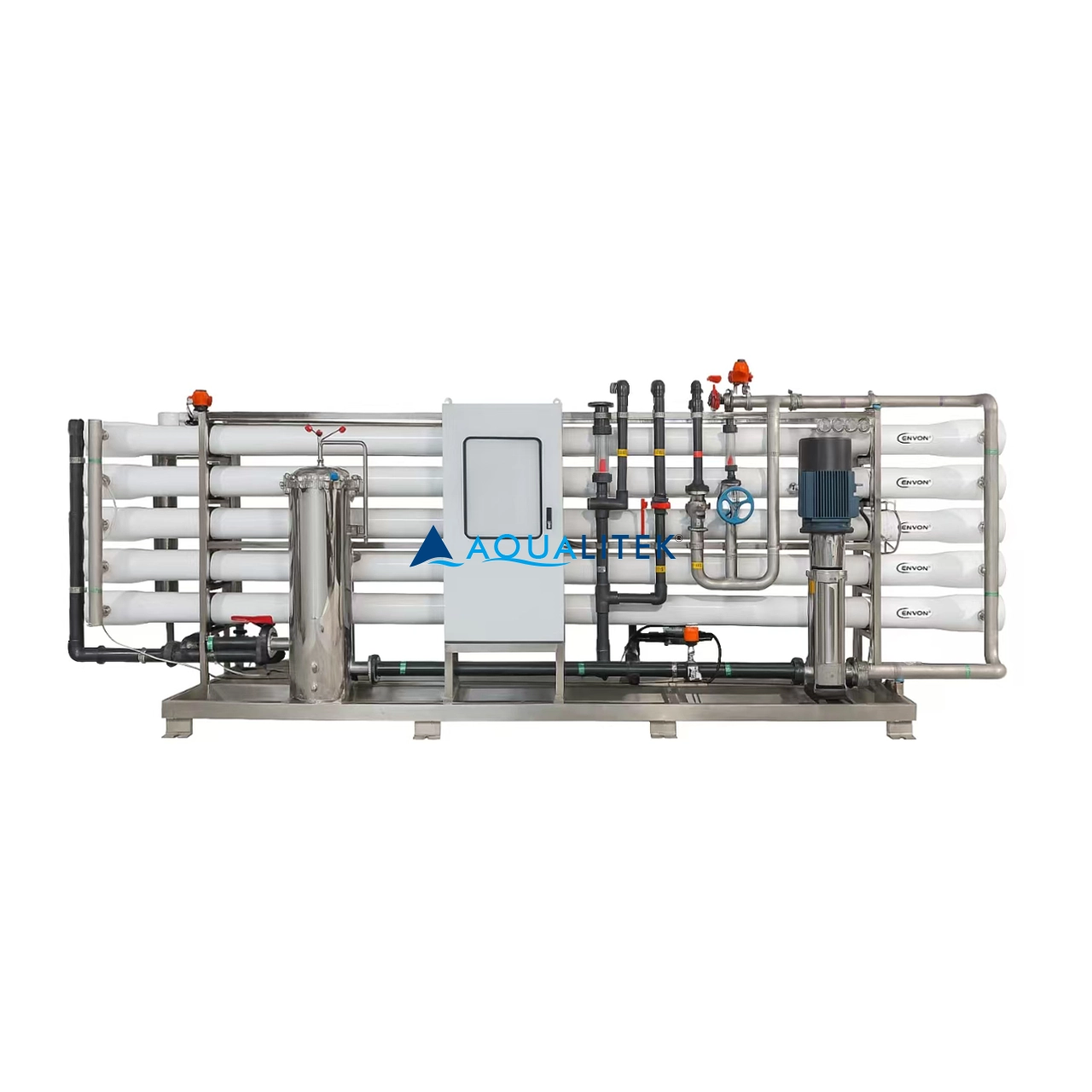

Calculate daily and hourly demand using both average and peak requirements. For continuous operations, specify required uptime and redundancy (N+1) for critical components like high-pressure pumps, membrane skids, and control systems. The AQUALITEK 4TPH Industrial Reverse Osmosis Water Purification RO System is rated at 4TPH (≈96 m3/day) and is a common choice for medium-scale manufacturing lines; when sizing systems, evaluate whether a single 4TPH unit meets peak demand or whether parallel units are needed for redundancy.

3. Regulatory and quality standards

Confirm applicable regulations and standards for your industry and location (discharge limits, reuse permits, hazardous waste handling). Reference authoritative guidance such as the information on reverse osmosis technology from Wikipedia and performance/quality standards from organizations like NSF International and local environmental agencies. Ensure the system and its materials meet requirements for pressure vessels, electrical safety, and, if needed, food or pharmaceutical contact standards.

Site Assessment and Civil/Mechanical Preparation

1. Physical footprint, structural support, and placement

Verify available space for the RO skid, pretreatment units (multimedia filters, activated carbon, water softeners), chemical dosing, storage tanks, and access for maintenance. Confirm floor loading capacity for skid-mounted systems and the need for secondary containment for chemical storage. Consider acoustic and vibration isolation for high-pressure pumps. The supplier should provide a footprint and lifting plan early in procurement to avoid retrofits.

2. Utilities: water, power, and drains

Document feed water flow and pressure availability. High-pressure pumps for RO require stable electrical supply—three-phase power is typical. Define electrical specifications (voltage, frequency, surge protection), compressed air needs (for actuators, diaphragm valves), and hot water or steam if CIP is required. Ensure adequate drainage for concentrate (brine) and backwash effluent, with compliance to local discharge permits. If municipal supply is intermittent or low-pressure, plan pre-boosting or raw water storage tanks.

3. Piping, valving, and instrumentation locations

Map inlet and outlet piping routes, minimising deadlegs and ensuring proper slopes for draining. Specify materials compatible with treated water (stainless steel, HDPE, or appropriate lined carbon steel). Include access points for sampling, instrumentation (flowmeters, pressure sensors, conductivity meters), and isolation valves for maintenance. Inline sampling points before/after pretreatment, before the RO membranes, and at product permeate are essential for commissioning and ongoing performance checks.

Technical Selection: System Components and Pretreatment

1. Pretreatment options and rationale

Pretreatment protects RO membranes and improves recovery. Common components include multimedia filtration or sand filters (for turbidity), activated carbon (for organics and chlorine removal), water softeners or antiscalant dosing (for hardness control), and cartridge filters (1–5 µm). Choose pretreatment based on feedwater test results—e.g., if free chlorine is present, carbon is mandatory to protect polyamide membranes. Below is a comparison table of typical pretreatment choices and their best-use cases:

| Pretreatment | Primary Function | When to Specify |

|---|---|---|

| Multimedia (sand) filters | Remove turbidity, particulates, SDI reduction | Raw surface water or high-suspended solids |

| Activated carbon | Remove free chlorine and organics | Municipal supply with chlorination or high TOC |

| Water softener / Antiscalant dosing | Control hardness and scaling potential | Hard raw water (high Ca/Mg) or high silica |

| Cartridge filters (1–5 µm) | Protect RO membranes from remaining particulates | Always recommended before membrane skid |

2. Membrane types and recovery strategies

Select membrane chemistry (polyamide thin-film composite is common for brackish water and industrial deionization) and consider high-recovery designs if concentrate disposal is constrained. High-recovery RO reduces wastewater but increases fouling and requires robust pretreatment. Evaluate single-pass vs two-pass RO for applications that demand ultra-low conductivity. For electronic cleaning water, a two-pass or RO + electrodeionization (RO+EDI) may be required to meet resistivity targets.

3. Controls, automation, and monitoring

Modern industrial RO systems should include PLC-based control with HMI for local operations, SCADA/Modbus integration for plant-level monitoring, and alarms for key parameters: feed pressure, permeate conductivity, concentrate flow, and pump faults. Automated dosing (antiscalant, acid) and CIP scheduling reduce operational burden. Ensure the control package allows data logging for traceability and regulatory reporting.

Procurement, Commissioning and Lifecycle Considerations

1. Procurement checklist and contractual items

Key procurement items to include in the purchase order and contract: detailed technical specifications (feed/product quality, recovery), delivery & installation scope, factory acceptance test (FAT) criteria, site acceptance test (SAT) and performance guarantee, spare parts list, warranty terms, training, and commissioning schedule. Specify acceptance criteria numerically (e.g., permeate conductivity, recovery percentage, SDI < 3) and include penalties or corrective actions if guarantees are not met.

2. Commissioning & performance testing

Commissioning should include flushing, integrity checks, stepwise start-up of pretreatment and RO skid, membrane flux stabilization, and performance validation (permeate TDS/conductivity, production vs design, chemical consumption). Document FAT and SAT test reports. For compliance and traceability, store commissioning logs and instrument calibration certificates.

3. Operation, maintenance and lifecycle cost planning

Develop a maintenance plan including routine checks (membrane permeate flow, salt rejection, pressure differentials across filters), scheduled CIP procedures, membrane replacement timelines (often 3–7 years depending on feedwater and operation), and spare parts inventory (seals, membranes, gauges). Model lifecycle costs including energy consumption (high-pressure pump power), chemical costs (antiscalant, acid/alkali, cleaning chemicals), membrane replacement, and disposal of concentrate. Use these figures to calculate total cost of ownership (TCO) and payback from replacing purchased high-quality water or lowering wastewater surcharges.

Brand Fit: Why AQUALITEK for Industrial RO Projects

1. Product focus and suitability

AQUALITEK 4TPH Industrial Reverse Osmosis Water Purification RO System, high-efficiency industrial-grade RO water treatment plant for manufacturing & processing, commercial reverse osmosis filtration system ideal for electronic component cleaning water use.

The 4TPH unit aligns well with medium-scale industrial needs where reliable, continuous permeate flow and precise water quality are required. Its modular design simplifies on-site installation and future capacity scaling (parallel skids for redundancy).

2. Technical support, warranty and training

Choose a vendor that offers comprehensive commissioning, operator training, and accessible technical support. AQUALITEK provides factory testing, on-site commissioning, and operator handover, reducing ramp-up time and ensuring performance aligns with contractual guarantees. Check warranty scope and response times for critical spare parts and service visits.

3. Sustainability and compliance advantages

Optimised systems can reduce fresh water usage and minimize concentrate discharge via higher recovery designs and effective pretreatment. When planning an RO installation, consult environmental guidance such as the US EPA water research resources (EPA Water Research) and quality standards from NSF International for material and performance expectations.

FAQ — Common Questions About Procuring and Installing an Industrial RO System

Q: How do I know if a 4TPH RO system is the right size?

A: Match the 4TPH nameplate (about 96 m3/day) to your peak hourly and daily demands, factoring in redundancy and planned growth. If continuous operation is needed at higher flow rates, consider parallel units or larger Capacity models. Confirm with a site water balance to ensure supply and storage meet production needs.

Q: What pretreatment is absolutely required for RO membranes?

A: At minimum, remove particulates (cartridge filters), remove free chlorine (activated carbon) and control hardness/scaling (antiscalant or softening) based on feedwater analysis. The specific pretreatment package is determined by measured SDI, hardness, iron/manganese, and organics.

Q: What are realistic operating costs for an industrial RO system?

A: Operating costs include energy (dominant for high-pressure pumps), chemicals (antiscalants, cleaning agents), membrane replacement, and routine consumables (filters). Energy intensity varies with feedwater TDS and recovery; estimate pump energy using design pressures and motor efficiencies. For budgeting, request typical specific energy consumption (kWh/m3) and chemical usage from suppliers during procurement.

Q: How long do RO membranes last?

A: Membrane life typically ranges from 3–7 years depending on feedwater quality, pretreatment effectiveness, and operation (recovery and flux). Regular monitoring, proper CIP, and avoiding oxidant exposure extend membrane life.

Q: Where can I find technical references for reverse osmosis?

A: Useful, authoritative references include the Reverse osmosis overview on Wikipedia, standards and guidance from NSF International, and water research publications by the US EPA. These sources provide background on technology, performance parameters, and regulatory considerations.

Next Steps — Contact and Product Information

Installation planning is incomplete without addressing upstream risks, making pretreatment requirements before an industrial RO system essential for stable operation.

If your project aligns with the specifications above and you need a compact, reliable industrial RO solution, consider the AQUALITEK 4TPH Industrial Reverse Osmosis Water Purification RO System. For a site-specific quote, FAT/SAT planning, or to schedule a water test and system sizing consultation, contact our sales and engineering team or view full product details:

View product: AQUALITEK 4TPH Industrial Reverse Osmosis Water Purification RO System • Contact customer service for a quotation and commissioning schedule.

Why Choose a 30TPH Industrial Reverse Osmosis (RO) System

How to Maintain and Clean Your Water Softener System

Sustainable Water Purification: Reduce Waste and Energy — Practical Guide by Aqualitek

Operational Costs and ROI of Commercial Reverse Osmosis Systems

FAQ-aqualitek

How do I choose the right water treatment system for my needs?

The choice depends on factors such as water quality, application, flow rate, and purification requirements. Our team of experts can analyze your water source and recommend the most suitable solution for residential, commercial, or industrial applications.

Can AQT provide custom water treatment solutions?

Yes! We specialize in OEM/ODM water treatment solutions and can design custom filtration systems tailored to your business, industry, or brand requirements. Our team can assist with system design, branding, private labeling, and technical support.

Solutions

What is the difference between Reverse Osmosis (RO), Ultrafiltration (UF), and Nanofiltration (NF)?

1. Reverse Osmosis (RO): Removes up to 99.9% of contaminants, including salts, bacteria, viruses, and heavy metals.

2. Ultrafiltration (UF): Uses a membrane filtration process to remove bacteria and particles, while retaining essential minerals.

3. Nanofiltration (NF): Falls between RO and UF, removing some salts and organic compounds while allowing certain minerals to pass through.

Does AQT provide technical support and after-sales service?

Yes! We offer comprehensive technical support, including installation guidance, troubleshooting, spare parts supply, and ongoing maintenance assistance. Our after-sales team is available to ensure your water treatment system operates efficiently.

Ion Exchange Water Treatment Systems

What is the difference between softening and deionization?

Softening removes only hardness ions (Ca²⁺, Mg²⁺), while deionization removes both cations and anions to produce high-purity water.

30TPH Industrial Reverse Osmosis (RO) System

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo