Evaluating Flow Capacity of Multi-cartridge Filter Housings

- Evaluating Flow Capacity of Multi-cartridge Filter Housings

- Why evaluating flow capacity matters for cartridge filter housing

- Understanding flow capacity and basic flow relationships in cartridge filter housing

- Key factors that affect flow capacity of a cartridge filter housing

- How cartridge count affects flow capacity in a multi-cartridge filter housing

- Practical sizing steps for evaluating flow capacity

- Example comparison table: typical illustrative flow ranges per cartridge

- Estimating pressure drop and fouling behavior for cartridge filter housings

- Fouling safety factor and replacement interval planning

- Material and construction benefits of Multi-cartridge Filter Housing stainless steel micron filter for water purification

- Operational considerations: valves, bypass, and instrumentation that affect true flow capacity

- Prefiltration and staged filtration to improve effective flow capacity

- Cost, footprint, and maintenance trade-offs when increasing flow capacity

- Checklist: what to request from vendors when evaluating cartridge filter housing flow capacity

- Brand alignment and advantages for buyers: Multi-cartridge Filter Housing stainless steel micron filter for water purification

- Frequently Asked Questions (FAQ)

- Contact and next steps

- Authority and further reading

Evaluating Flow Capacity of Multi-cartridge Filter Housings

Why evaluating flow capacity matters for cartridge filter housing

Selecting the right cartridge filter housing is more than matching inlet and outlet sizes. The flow capacity of a cartridge filter housing determines whether a filtration train will meet process demand without excessive pressure drop, premature cartridge replacement, or risk to process quality. For industrial and municipal water purification, a proper evaluation of flow capacity for a cartridge filter housing ensures reliable performance, energy efficiency, and predictable operating cost. In this article we look specifically at multi-cartridge filter housing applications and the product named Multi-cartridge Filter Housing stainless steel micron filter for water purification, and we show methods to size and evaluate flow in real-world terms.

Understanding flow capacity and basic flow relationships in cartridge filter housing

Flow capacity is the volume of liquid a cartridge filter housing can pass while maintaining acceptable pressure drop and filtration performance. Two practical relationships to keep in mind are: 1) For a given cartridge and open-clean condition, flow increases with driving pressure, and 2) Pressure drop increases as cartridges load with solids. Cartridge filter housings rarely behave linearly across all conditions, so design needs to consider initial clean pressure drop, acceptable operating pressure drop, and the fouling profile over time.

When evaluating a cartridge filter housing, engineers typically use manufacturer flow vs. pressure-drop curves for specific cartridge media and micron ratings. In absence of exact curves, use conservative empirical values and apply safety factors for fouling and variability in feed water quality.

Key factors that affect flow capacity of a cartridge filter housing

Several interdependent variables determine effective flow capacity. For any multi-cartridge cartridge filter housing these must be reviewed during selection and sizing:

- Cartridge type and media: wound, pleated, activated carbon, or membrane cartridges have different permeability and dirt-holding capacities.

- Micron rating: finer ratings increase initial pressure drop and reduce flow per cartridge.

- Cartridge length and diameter: longer and larger cartridges provide greater filter area and higher flow per element.

- Number of cartridges in the housing: multi-cartridge housings increase surface area and reduce face velocity for the same flow, lowering pressure drop.

- Housing design and internal hydraulics: inlet distribution, internal piping, and headspace influence flow uniformity between cartridges.

- Process pressure and allowable pressure drop: available net positive inlet pressure limits practical flow and the number of cartridges required.

- Feed water quality and fouling rate: turbid or particle-laden water shortens service life and raises pressure drop quickly.

- Material and construction: stainless steel housings are preferred for longevity and sanitary or high-purity services; they enable higher working pressures and easier cleaning.

How cartridge count affects flow capacity in a multi-cartridge filter housing

One of the most direct ways to increase flow capacity is to add more cartridges. Doubling cartridge count does not always double throughput because internal hydraulics and manifold losses may cause diminishing returns at higher flows. Still, moving from single-cartridge housings to multi-cartridge configurations typically provides linear improvements in clean-water capacity up to design limits. Consideration of even flow distribution, gasket sealing, and equalized pressure across cartridges is critical to achieve expected gains.

Practical sizing steps for evaluating flow capacity

Follow a stepwise approach when sizing a cartridge filter housing for target flow:

- Define process requirements: required flow rate (GPM or m3/h), maximum allowable pressure drop across the filter, operating pressure and temperature, and water quality parameters (TSS, turbidity, chemistry).

- Select candidate cartridge media and micron rating based on target contaminant removal and expected dirt load.

- Gather manufacturer flow vs. pressure-drop curves for the chosen cartridge sizes and media. If unavailable, use conservative empirical ranges provided below.

- Calculate required cartridge count. Use the cartridge clean-flow capacity at the allowable pressure drop as the baseline per-cartridge flow, then divide process flow by that per-cartridge flow and round up. Apply a fouling safety factor (commonly 1.25 to 2.0 depending on feed variation).

- Check housing hydraulics and vendor documentation to confirm the physical housing supports the number and type of cartridges, inlet/outlet sizes, and pressure ratings.

- Finalize selection with maintenance and replacement interval targets in mind: more cartridges often mean longer runtimes between cartridge changes for given feed quality.

Example comparison table: typical illustrative flow ranges per cartridge

Table below gives illustrative clean-water flow ranges per cartridge by cartridge style and micron rating. These are typical industry ranges for standard 10-inch and 20-inch cartridges with standard diameters. Use manufacturer charts for exact values; these numbers are for sizing guidance and comparison only.

| Cartridge Type | Length | Micron Rating | Typical Clean Flow per Cartridge (GPM) | Notes |

|---|---|---|---|---|

| Pleated Polypropylene | 10 | 10 μm | 8 - 12 | Good dirt holding and low ΔP |

| Pleated Polypropylene | 10 | 1 μm | 2 - 5 | Finer removal reduces flow |

| Pleated Polypropylene | 20 | 10 μm | 15 - 22 | Longer cartridge roughly doubles area |

| Wound String | 10 | 5 μm | 4 - 8 | Higher tortuosity, lower flow |

| Activated Carbon | 10 | Nominal | 3 - 8 | Sorption and pressure drop vary by grade |

Example sizing: For a process needing 120 GPM using 10 10 μm pleated cartridges with an expected clean flow of 10 GPM per cartridge, you would start with 120/10 = 12 cartridges. Apply a fouling factor of 1.25, so specify 15 cartridges or choose a standard housing with 12 cartridges and accept more frequent changeouts depending on feed water quality.

Estimating pressure drop and fouling behavior for cartridge filter housings

Pressure drop across a cartridge filter housing consists of several components: inlet piping losses, inlet manifold distribution, cartridge clean-flow pressure drop, and outlet manifold losses. The cartridge clean-flow pressure drop varies by cartridge and micron rating and is often given at specific flow rates. As cartridges load with solids pressure drop increases; this rate depends on particle size distribution and cake formation characteristics.

Practical tips:

- Ask cartridge vendors for flow vs. ΔP curves for both clean and representative loaded conditions.

- Define the maximum allowable ΔP across the housing that still allows backpressure or downstream pump head requirements.

- Use online calculators or simple linear approximations only for preliminary sizing; validate with vendor data for final design.

Fouling safety factor and replacement interval planning

Because feed quality can vary, apply a fouling safety factor when calculating total cartridge area. Typical safety factors range from 1.25 for stable, low-turbidity feeds to 2.0 or higher for variable or poorly characterized feeds. Consider planned cartridge change intervals in operations planning: selecting a housing with more cartridges reduces change frequency but raises initial capital cost and footprint.

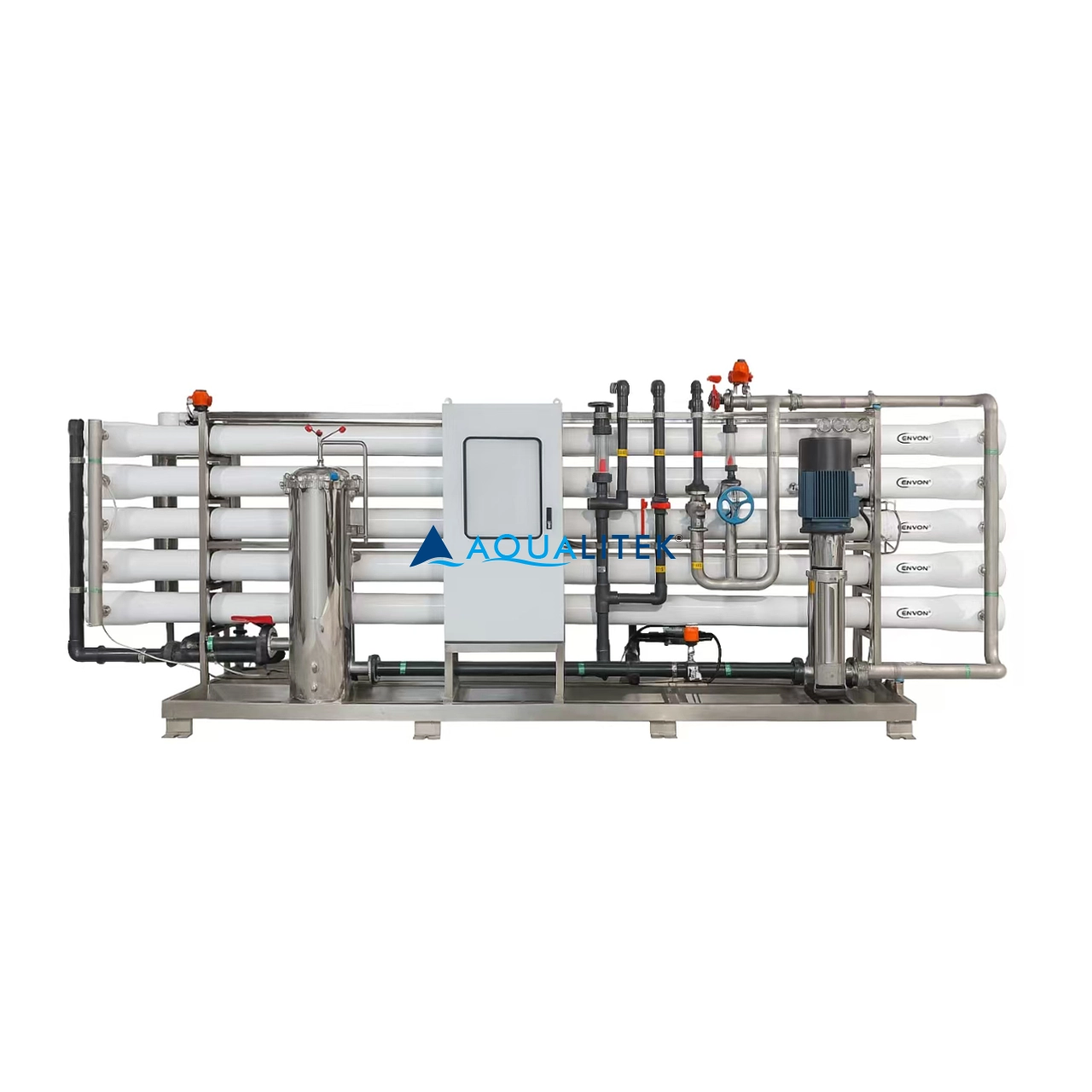

Material and construction benefits of Multi-cartridge Filter Housing stainless steel micron filter for water purification

The product Multi-cartridge Filter Housing stainless steel micron filter for water purification combines a multi-cartridge design with stainless steel construction. Stainless steel housings offer several advantages when evaluating flow capacity and system life:

- Higher allowable working pressures and temperatures versus polymer housings, allowing greater system head and wider application range.

- Robust manifold and closure designs that maintain even flow distribution, which preserves per-cartridge flow capacity and reduces bypass risk.

- Sanitary-grade finishes and welds for potable and high-purity applications, reducing sites for fouling and enabling easier cleaning.

Operational considerations: valves, bypass, and instrumentation that affect true flow capacity

System-level components change effective flow capacity. Properly sized inlet/outlet piping, low-loss manifolds, full-port isolation valves, and prefiltration stages all help maintain lower pressure drop across the cartridge filter housing and extend cartridge life. Adding differential pressure gauges across the housing and per-stage sampling ports provides the operating data needed to optimize replacement schedules and avoid sudden flow losses.

Prefiltration and staged filtration to improve effective flow capacity

Adding a coarse prefilter or a sedimentation step upstream reduces particulate load on fine cartridges and can dramatically increase the effective runtime and average flow per cartridge. For water purification systems, common configurations include a multi-cartridge housing for coarse removal followed by finer cartridges or membrane polishing stages. This staged approach is especially relevant for the Multi-cartridge Filter Housing stainless steel micron filter for water purification, which performs best when protecting fine media downstream.

Cost, footprint, and maintenance trade-offs when increasing flow capacity

Increasing flow capacity by adding cartridges raises initial cost, weight, and footprint. A balanced decision weighs capital expense against operating savings from fewer cartridge changes, lower energy consumption due to reduced pumping loss, and reduced downtime. Stainless steel multi-cartridge housings often cost more than polymer alternatives but can be more economical over the life cycle in demanding environments where corrosion or high pressure is present.

Checklist: what to request from vendors when evaluating cartridge filter housing flow capacity

When assessing options, request the following items from housing and cartridge vendors:

- Flow vs. pressure-drop curves for selected cartridges at relevant temperatures and fluid viscosities.

- Recommended maximum flow per cartridge and per housing model.

- Hydraulic drawings showing inlet/outlet distribution and manifold losses.

- Material certificates for stainless steel housings and compliance statements for potable water if applicable (NSF, WRAS, etc.).

- Maintenance drawings showing cartridge access, sealing method, and O-ring materials.

- Service life and fouling data from similar installations if available.

Brand alignment and advantages for buyers: Multi-cartridge Filter Housing stainless steel micron filter for water purification

Choosing a Multi-cartridge Filter Housing stainless steel micron filter for water purification provides buyers with a package optimized for high throughput, durability, and long-term performance. Key brand advantages include:

- Stainless steel construction for corrosion resistance and high-pressure ratings.

- Flexible cartridge layout to scale flow capacity by adding or removing elements.

- Sanitary and industrial surface finishes suitable for water purification and demanding process environments.

- Design focus on even flow distribution to maximize effective per-cartridge capacity.

- Compatibility with a wide range of cartridge media and micron ratings for staged or final filtration.

Frequently Asked Questions (FAQ)

Q1: How do I determine the number of cartridges needed for my flow?

A1: Determine the required system flow, locate per-cartridge clean-flow at allowable ΔP from the cartridge manufacturer, divide the system flow by the per-cartridge flow, then apply a fouling safety factor (1.25–2.0) before rounding up to a standard housing size.

Q2: Can I increase flow by simply increasing feed pressure?

A2: Increasing feed pressure can increase flow, but it also raises stress on cartridges and seals and may saturate downstream equipment. Evaluate manufacturer maximum pressures and be mindful that higher flow accelerates fouling and may reduce cartridge life.

Q3: Is stainless steel necessary for all multi-cartridge housings?

A3: No. Stainless steel is preferred for corrosive or high-pressure applications and for sanitary uses. Polypropylene or FRP housings may be suitable for low-pressure, non-corrosive environments and are often more economical.

Q4: How often should cartridges be changed?

A4: Change frequency depends on feed water quality, cartridge micron rating, and allowed ΔP. Monitor differential pressure and establish change criteria, commonly between 10–25 psi above the clean differential pressure, or based on scheduled runtime from historical data.

Q5: Can multi-cartridge housings be used for potable water?

A5: Yes, when built with appropriate materials, finishes, and certified cartridges, multi-cartridge housings are widely used in potable water systems. Look for NSF or equivalent certifications where required.

Contact and next steps

If you need assistance sizing a cartridge filter housing for a specific water purification application, or want to review product specifications for the Multi-cartridge Filter Housing stainless steel micron filter for water purification, contact our technical sales team. We can provide flow vs. ΔP curves, help select cartridge media, and recommend housings with the right cartridge count for your required flow and service interval. View the product page or contact support to request technical drawings and a quotation.

Authority and further reading

Below are authoritative resources to consult for deeper technical references and standards related to filtration and water treatment:

- Wikipedia, Filter (technology): https://en.wikipedia.org/wiki/Filter_(technology)

- US Environmental Protection Agency, Water Research and Treatment: https://www.epa.gov/water-research

- World Health Organization, Drinking-water: https://www.who.int/health-topics/drinking-water

- NSF International, How filters work and standards: https://www.nsf.org

- Generic industry guidance and manufacturer technical resources; consult specific cartridge suppliers for flow/ΔP curves and certified data.

Authority references above provide general background. For cartridge- and housing-specific engineering, always request vendor datasheets and validation test reports to confirm performance under your operating conditions.

Contact us to get product specs, request a quote, or schedule a technical consultation for your cartridge filter housing needs.

Procurement Checklist: Installing an Industrial RO System

How to Maintain Your Water Purification System: A Guide

4TPH Industrial Reverse Osmosis RO System: Technical Overview

Selecting the Right Commercial RO System for High-Capacity Needs

Ion Exchange Water Treatment Systems

What is the difference between softening and deionization?

Softening removes only hardness ions (Ca²⁺, Mg²⁺), while deionization removes both cations and anions to produce high-purity water.

Can ion exchange work with seawater or high-TDS water?

Ion exchange is more suitable for low to moderate TDS water. High-TDS applications often use RO as a primary treatment.

FAQ-aqualitek

Can AQT provide custom water treatment solutions?

Yes! We specialize in OEM/ODM water treatment solutions and can design custom filtration systems tailored to your business, industry, or brand requirements. Our team can assist with system design, branding, private labeling, and technical support.

What industries does AQT serve?

We provide water treatment solutions for a wide range of industries, including:

Industrial Manufacturing – Process water treatment, cooling water, and boiler feed.

Hospitality & Commercial – Hotels, restaurants, and office buildings.

Residential Applications – Drinking water purification and softening.

Healthcare & Pharmaceuticals – Ultra-pure water for laboratories and hospitals.

Municipal & Public Utilities – Water supply and wastewater treatment.

Food & Beverage Processing – Filtration for beverage production and food safety.

Solutions

What types of water treatment systems does AQT offer?

AQT provides a wide range of water purification solutions, including reverse osmosis (RO) systems, ultrafiltration (UF) systems, nanofiltration (NF) systems, deionization (DI) systems, electro-deionization (EDI) systems, chemical dosing systems, and water softeners. We also supply spare parts and components for water treatment systems.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWE Series

TWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for tap water (lower TDS). The large volumes can help meet your a variety of industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo