How to scale an RO solution for large industrial demand?

Industrial Reverse Osmosis (RO) systems are pivotal in providing high-quality water for various industrial applications. They effectively remove dissolved salts, heavy metals, and organic compounds, ensuring water purity essential for manufacturing, cooling, and other industrial processes.

When scaling an RO solution to meet large industrial demands, several critical factors must be considered:

1. System Capacity and Flow Rate

Industrial RO systems are designed to handle substantial water volumes. For instance, large-scale systems can produce between 200,000 to 900,000 gallons of water per day, catering to extensive industrial needs.

2. Feed Water Quality and Pretreatment

The quality of the incoming water significantly influences the RO system's performance and longevity. High Total Dissolved Solids (TDS) levels, hardness, and the presence of contaminants necessitate comprehensive pretreatment processes. This may include sediment filtration, activated carbon filtration, and water softening to protect the RO membranes and ensure optimal operation.

3. Membrane Selection and Maintenance

Choosing the appropriate RO membranes is crucial for system efficiency. Membranes should be selected based on the specific contaminants present in the feed water and the desired water quality. Regular maintenance, including cleaning-in-place (CIP) protocols and scheduled replacements, is essential to extend membrane life and maintain system performance. ((https://www.aqualitek.com/top-5-industrial-reverse-osmosis-systems-in-2026.html))

4. Energy Efficiency

Energy consumption is a significant operational cost for large-scale RO systems. Implementing energy-efficient designs, such as utilizing low-energy membranes and optimizing system configurations, can lead to substantial cost savings. For example, some systems are designed to achieve high recovery rates with minimal energy usage, enhancing overall efficiency. ((https://www.aqualitek.com/best-industrial-reverse-osmosis-systems-2026.html))

5. System Integration and Automation

Integrating the RO system with existing industrial processes and automating operations can improve efficiency and reduce the potential for human error. Automated monitoring and control systems allow for real-time performance tracking and quick response to any operational issues, ensuring consistent water quality and system reliability.

6. Compliance and Sustainability

Adhering to industry standards and environmental regulations is imperative. RO systems should be designed to meet specific water quality criteria and operate within environmental guidelines, promoting sustainability and ensuring compliance with local and international standards. ((https://www.aqualitek.com/top-5-industrial-reverse-osmosis-systems-in-2026.html))

7. Cost Considerations

While the initial investment for large-scale RO systems can be substantial, the long-term benefits, including reduced operational costs and improved water quality, often justify the expenditure. It's essential to conduct a thorough cost-benefit analysis to ensure the system aligns with the organization's financial and operational objectives.

8. Vendor Support and Service

Selecting a reputable vendor that offers comprehensive support, including installation, maintenance, and troubleshooting, is vital for the successful operation of large-scale RO systems. Ongoing technical support ensures the system operates at peak performance and addresses any issues promptly. ((https://www.aqualitek.com/top-5-industrial-reverse-osmosis-systems-in-2026.html))

In conclusion, scaling an industrial reverse osmosis system to meet large industrial demands requires careful planning, selection of appropriate components, and ongoing maintenance. By addressing these key considerations, industries can ensure a reliable and efficient water treatment process that supports their operational needs.

AQUALITEK's Advantages

AQUALITEK offers advanced industrial reverse osmosis systems tailored to meet large-scale water treatment requirements. With a focus on energy efficiency, high-quality components, and comprehensive support services, AQUALITEK ensures optimal performance and reliability for industrial applications.

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

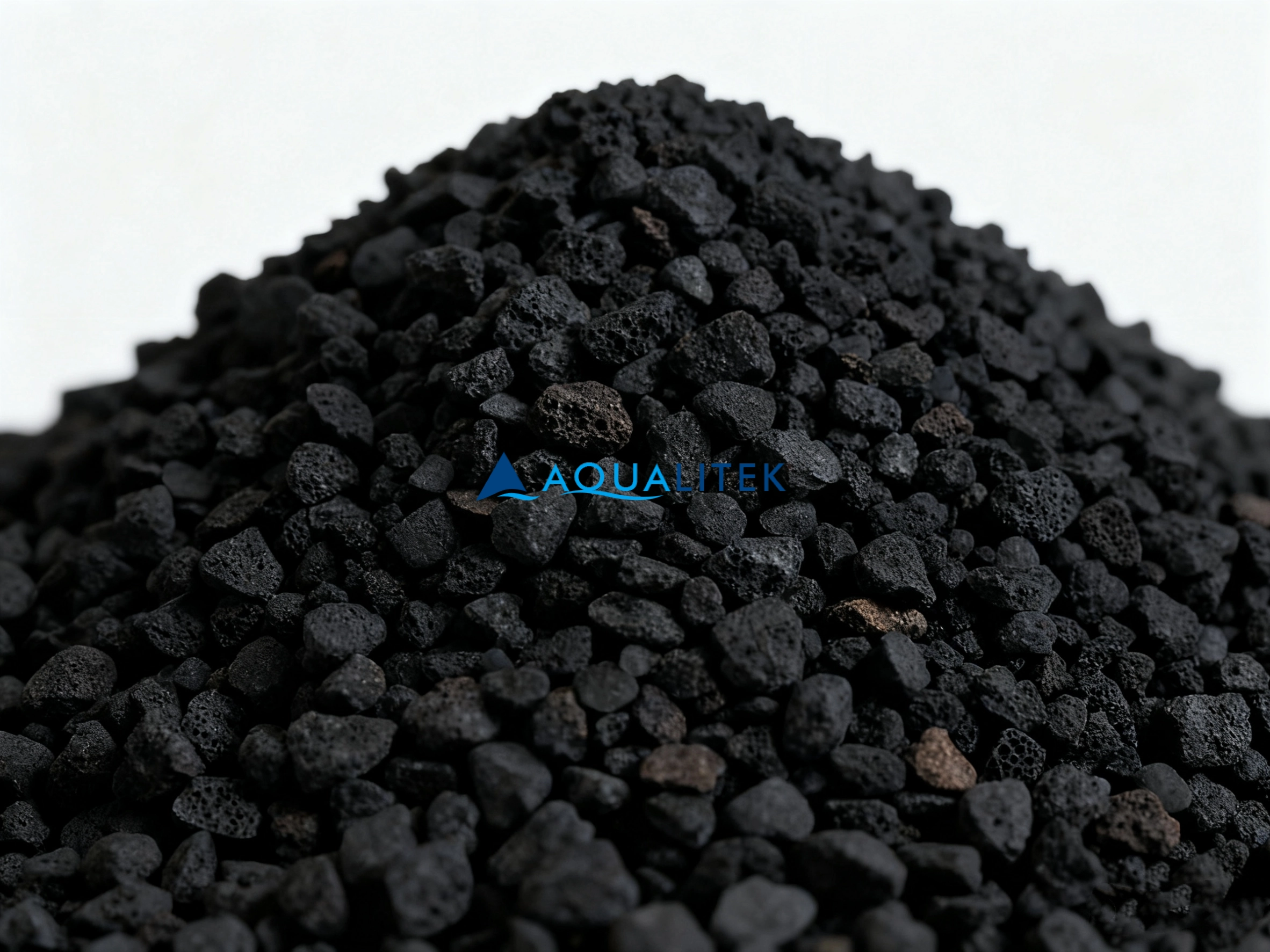

Anti-Scalant is a specialized water treatment chemical designed to prevent the formation of scale in reverse osmosis (RO) systems. Scaling is a common issue in RO systems, where minerals like calcium, magnesium, and silica precipitate and form hard deposits on the membrane surface. These deposits can clog the membranes, reduce water production efficiency, and increase operational costs.

RO chemical anti-scalants work by inhibiting the crystallization of scale-forming minerals, effectively keeping them in solution and preventing them from adhering to the membrane. This ensures the longevity and optimal performance of the RO system.

Anti-scalants are essential in applications with hard water or high mineral content, such as in industrial, municipal, and desalination plants.

These chemicals are highly effective in preventing scaling caused by common minerals such as calcium carbonate, calcium sulfate, barium sulfate, and silica, helping to extend the lifespan of the membranes, reduce cleaning cycles, and enhance system efficiency.

By incorporating an RO chemical anti-scalant into your water treatment process, you can improve the reliability and overall performance of your reverse osmosis system, ensuring consistent, high-quality water output while minimizing maintenance costs.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo