How Does a Water Purification System Work?

- How Does a Water Purification System Work?

- Core Components of a Water Purification System

- Pretreatment: sediment and particle removal

- Activated carbon and adsorption units

- Membrane separation: RO, NF, UF, MF

- Ion exchange and water softening

- Disinfection: UV, chlorination, ozone

- Stage-by-Stage: What Happens to Water Inside the System

- Pretreatment protects and stabilizes feed water

- Main treatment: filtration and separation

- Post-treatment ensures water is fit for use

- Comparing Key Water Treatment Technologies

- Technology comparison at a glance

- Design, Performance and Maintenance

- Key design factors affecting system performance

- Maintenance, cleaning, and life-cycle costs

- Choosing the Right Water Purification System

- Match system to source water and end use

- Consider certifications, warranties and support

- Environmental and Operational Considerations

- Waste streams and concentrate management

- Energy use and sustainability

- AQUALITEK: Advantages and Product Strengths

- Why choose AQUALITEK for water purification systems

- Membrane systems: high performance and flexibility

- Water filtering systems: practical protection and polishing

- Ion exchange systems: precise softening and demineralization

- Customized water purification systems: engineered solutions

- Frequently Asked Questions (FAQ)

- Q: What does a water purification system remove?

- Q: How effective is reverse osmosis (RO)?

- Q: Do I always need RO for home drinking water?

- Q: What maintenance does a water purification system need?

- Q: How can I reduce waste from membrane systems?

- Q: How do I choose between UF, NF and RO?

- Q: Does AQUALITEK provide worldwide support and customized systems?

- Q: Are there certifications I should look for when buying a system?

- Q: What is the first step to selecting the right system?

How Does a Water Purification System Work?

Understanding how a water purification system works helps you pick the right solution for safe, reliable water. A water purification system typically combines several treatment stages—pretreatment, filtration, membrane separation, disinfection, and post-treatment—to remove sediments, organic compounds, microorganisms, salts and other contaminants. Systems are tailored to source water (well, surface, municipal) and end use (drinking, process, boiler feed, reuse).

Core Components of a Water Purification System

Pretreatment: sediment and particle removal

Pretreatment removes sand, silt and large particles using sediment filters, multimedia filters, or automatic backwash units. This protects downstream membranes and extends the life of cartridges and membranes by lowering turbidity and particulate load. Typical sediment filters are rated in microns (e.g., 5–50 μm) depending on the application.

Activated carbon and adsorption units

Activated carbon filters adsorb chlorine, tastes, odors and many organic contaminants. They are essential ahead of membrane systems like reverse osmosis (RO) because chlorine damages RO membranes. Carbon can be granular (GAC) or in cartridge form and is chosen based on contact time and contaminant profile.

Membrane separation: RO, NF, UF, MF

Membrane technologies separate contaminants by size and charge. Reverse osmosis (RO) removes dissolved salts and many organics (typical salt rejection 95–99%). Nanofiltration (NF) targets divalent ions and larger organics. Ultrafiltration (UF) and microfiltration (MF) remove bacteria, protozoa and suspended solids; UF pore sizes are generally 0.01–0.1 μm, MF pores are larger. Membranes are the core of many modern purification systems.

Ion exchange and water softening

Ion exchange exchanges undesirable ions (commonly Ca2+ and Mg2+) for sodium or potassium to soften water or for demineralization when paired with other processes. It is widely used in industrial boiler feed, pharmaceutical, and some drinking water systems.

Disinfection: UV, chlorination, ozone

Disinfection inactivates biological pathogens. Ultraviolet (UV) irradiation is chemical-free and effective against bacteria and viruses when properly sized. Chlorination provides residual protection in distribution but requires careful dosing and contact time. Ozone is a powerful oxidant for organics and microbes but requires on-site generation and off-gas handling.

Stage-by-Stage: What Happens to Water Inside the System

Pretreatment protects and stabilizes feed water

Pretreatment reduces suspended solids, removes chlorine before membranes, adjusts pH if needed, and reduces fouling potential. Effective pretreatment improves recovery, lowers energy use, and reduces frequency of chemical cleaning for membranes.

Main treatment: filtration and separation

Filtration and membrane separation remove target contaminants. For example, an RO system will force water through a semipermeable membrane, producing permeate (purified water) and concentrate (reject). Process design balances recovery rate (how much feed becomes product) with fouling control and energy consumption.

Post-treatment ensures water is fit for use

After core treatment, post-treatment steps stabilize water (e.g., remineralization after RO to prevent corrosion and improve taste), add disinfection residual if required, and polish final quality. This ensures treated water meets regulatory and application-specific standards.

Comparing Key Water Treatment Technologies

Technology comparison at a glance

Different technologies target different contaminants. The table below summarizes typical removal sizes, primary targets, and practical pros and cons to help you compare solutions.

| Technology | Typical Particle/Contaminant Size | Primary Targets | Pros | Cons |

|---|---|---|---|---|

| Reverse Osmosis (RO) | ~0.0001 μm (dissolved salts) | Dissolved salts, metals, most organics | Very high removal for TDS; produces high-purity water | Generates concentrate; energy and pretreatment needs |

| Nanofiltration (NF) | ~0.001–0.01 μm | Divalent ions, larger organics | Lower pressure than RO; selective hardness reduction | Less effective on monovalent salts |

| Ultrafiltration (UF) | ~0.01–0.1 μm | Bacteria, protozoa, colloids | Robust for microbiological control; low chemical use | Does not remove dissolved salts |

| Microfiltration (MF) | ~0.1–10 μm | Suspended solids, some large microbes | Simple, low-energy; good pretreatment | Limited removal of viruses and dissolved contaminants |

| Activated Carbon | Adsorbs molecules (no pore size) | Chlorine, tastes, odors, many organics | Improves taste and protects membranes | Saturation requires replacement or regeneration |

| Ion Exchange | Chemical ion exchange | Hardness ions, specific ionic contaminants | Targeted removal; regenerable | Brine generation during regeneration |

| UV Disinfection | Photonic inactivation (no pore size) | Bacteria, viruses, protozoa (dependent on dose) | Chemical-free, immediate inactivation | No residual disinfectant; effectiveness reduced by turbidity |

Design, Performance and Maintenance

Key design factors affecting system performance

Design choices depend on feed water quality, desired product water quality, flow rate, space and budget. Important parameters include influent TDS, turbidity, organic load (TOC), microbial content, required recovery and allowable concentrate disposal. Correct pretreatment and correct membrane selection are critical for long-term performance and cost control.

Maintenance, cleaning, and life-cycle costs

Routine maintenance includes replacing sediment and carbon filters, monitoring membrane performance (flux, rejection), periodic chemical cleanings to remove scale/organic fouling, and replacing UV lamps or resins. Lifecycle costs include energy, consumables, replacement membranes and waste handling—these often outweigh initial capital cost over years of operation.

Choosing the Right Water Purification System

Match system to source water and end use

Start with a reliable water analysis to identify target contaminants. For municipal feed with low TDS, point-of-use RO or UF plus carbon may suffice. For brackish or seawater, RO is the common choice. For industrial reuse or pharmaceutical uses, multi-stage systems with NF/RO and polishing steps are typical.

Consider certifications, warranties and support

Choose systems and components certified to recognized standards (NSF/ANSI for drinking water components, ISO manufacturing standards) and verify supplier capabilities for engineering support, spare parts and local service. Proper commissioning and training reduce downtime and extend system life.

Environmental and Operational Considerations

Waste streams and concentrate management

Membrane systems generate concentrate (brine) that must be managed. Options include discharge to sewer (where permitted), evaporation, zero liquid discharge (ZLD) systems, or blending and dilution. Minimizing waste through improved recovery, pretreatment, and process integration reduces environmental impact and operating cost.

Energy use and sustainability

Energy is a major operating cost for high-pressure systems like RO. Energy recovery devices for seawater and high-recovery RO plants can substantially reduce power demand. System selection should balance purity needs with energy and environmental goals.

AQUALITEK: Advantages and Product Strengths

Why choose AQUALITEK for water purification systems

AQUALITEK Water Treatment Technologies Co., Ltd., based in Guangzhou, China, combines engineering expertise, advanced manufacturing and customized design to provide complete water treatment solutions. Their strengths include end-to-end product ranges (pretreatment, core treatment, polishing and recycling), global supply capabilities, and tailored systems for residential, commercial and industrial needs. AQUALITEK emphasizes reliability, cost-effectiveness and sustainability in delivered systems.

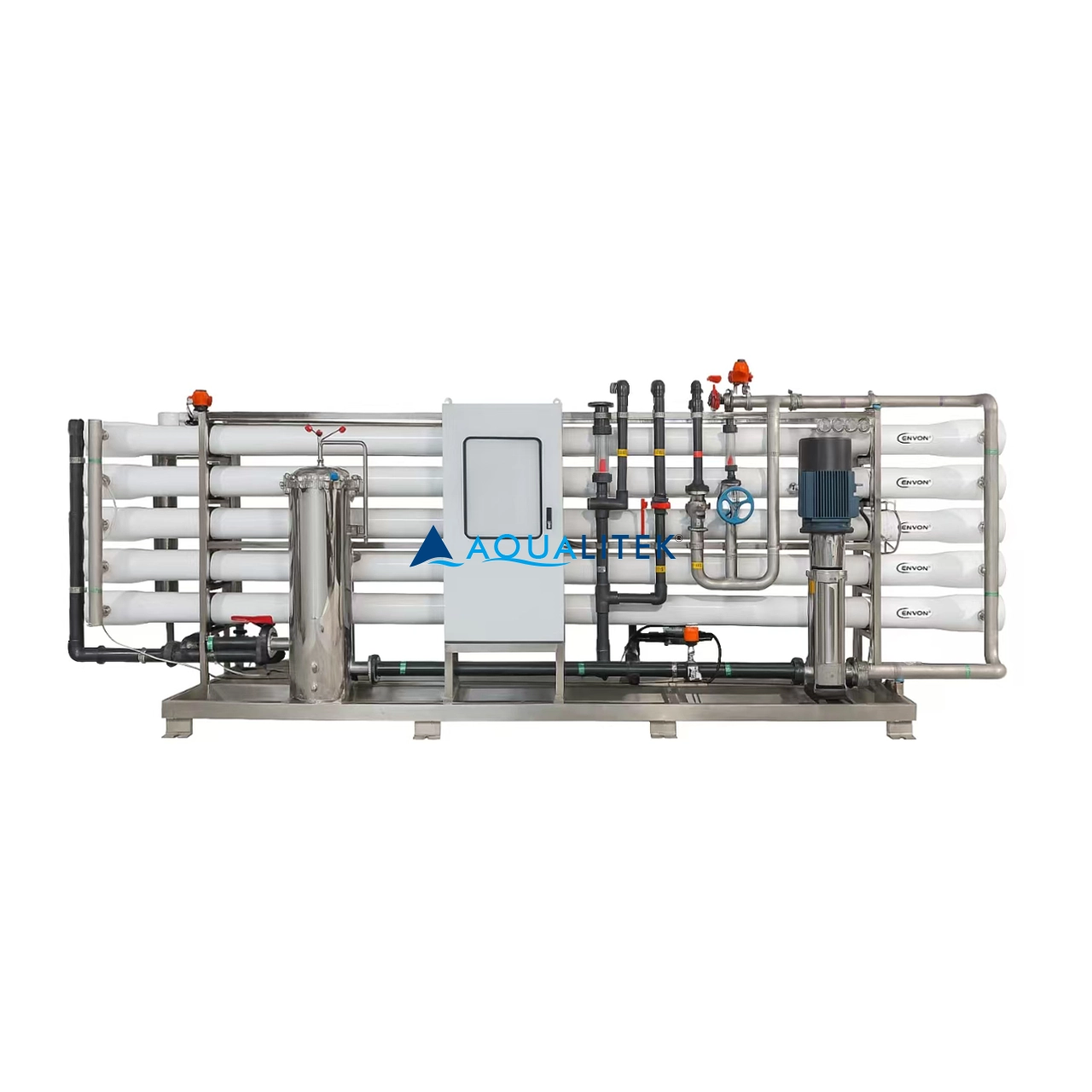

Membrane systems: high performance and flexibility

AQUALITEK's membrane systems include RO, NF and UF modules designed for stable flux and good rejection performance. They offer modular skids for ease of installation and integration with pretreatment and energy recovery. These systems are engineered for optimized recovery and membrane life through correct pretreatment and automated cleaning cycles.

Water filtering systems: practical protection and polishing

The company's water filtering systems cover multimedia media filters, activated carbon units and cartridge housings to handle turbidity, chlorine, tastes and odors. These filters are sized for different flow rates and are configured to protect downstream membranes and to deliver potable water quality where needed.

Ion exchange systems: precise softening and demineralization

AQUALITEK provides ion exchange units for water softening, demineralization, and targeted ion removal. Their systems include resin tanks, automated controls and regeneration management—suitable for industrial process needs and applications that require low hardness or low conductivity water.

Customized water purification systems: engineered solutions

For complex applications, AQUALITEK offers customized purification systems combining pretreatment, membrane separation, ion exchange, disinfection and post-treatment. These engineered solutions are tailored to site conditions, regulatory requirements and customer budgets, with integrated controls and package skids for fast deployment.

Frequently Asked Questions (FAQ)

Q: What does a water purification system remove?

A water purification system removes suspended solids, sediments, organic compounds, chlorine, tastes and odors, many dissolved salts and metals, and microbiological contaminants depending on the technologies used (e.g., RO, UF, activated carbon, UV).

Q: How effective is reverse osmosis (RO)?

RO is highly effective for dissolved solids and many organics. Typical salt rejection for modern RO membranes is in the range of about 95–99%, making it a common choice for producing low-TDS water for drinking, industrial processes, or as a step in reuse systems.

Q: Do I always need RO for home drinking water?

Not always. If municipal water already meets quality standards and only taste or chlorine is an issue, carbon filters or UF systems may be sufficient. RO is recommended when TDS, heavy metals, or specific dissolved contaminants exceed desired levels.

Q: What maintenance does a water purification system need?

Maintenance typically includes replacing cartridge and carbon filters, monitoring and periodically cleaning or replacing membranes, checking and replacing UV lamps as needed, regenerating ion exchange resins, and routine inspection of pumps, valves and control systems. A preventive maintenance plan increases uptime and lowers lifecycle cost.

Q: How can I reduce waste from membrane systems?

Improve pretreatment to lower fouling, operate at optimized recovery, use energy recovery devices where applicable, and consider concentrate management strategies such as blending, evaporation or ZLD for industrial sites. Proper design and control reduce unnecessary waste and operating costs.

Q: How do I choose between UF, NF and RO?

Choose based on targeted contaminants: MF/UF for suspended solids and microbes; NF when you need to soften water and remove larger dissolved organics or divalent ions; RO when you need to significantly lower TDS and dissolved salts. A water analysis guides the choice.

Q: Does AQUALITEK provide worldwide support and customized systems?

Yes. AQUALITEK specializes in customized water purification systems for residential, commercial and industrial customers, offering tailored engineering, manufacturing and aftermarket support to meet diverse application needs globally.

Q: Are there certifications I should look for when buying a system?

For drinking water components, look for certifications like NSF/ANSI where applicable. For industrial equipment, check ISO manufacturing standards, CE marking for relevant markets, and supplier references for field performance and service capability.

Q: What is the first step to selecting the right system?

Begin with a comprehensive water analysis and clarity on end-use requirements (e.g., potable water, process water, boiler feed, reuse). This data allows an engineer to design an efficient, cost-effective treatment train that meets your quality targets and operational constraints.

Maintenance and Lifecycle Considerations for Electrodeionization

Operational Costs and ROI of Commercial Reverse Osmosis Systems

Reverse Osmosis for Well Water: When and Why to Use It

Selecting Pretreatment for Industrial RO Systems

FAQ-aqualitek

What is the difference between Reverse Osmosis (RO), Ultrafiltration (UF), and Nanofiltration (NF)?

1. Reverse Osmosis (RO): Removes up to 99.9% of contaminants, including salts, bacteria, viruses, and heavy metals.

2. Ultrafiltration (UF): Uses a membrane filtration process to remove bacteria and particles, while retaining essential minerals.

3. Nanofiltration (NF): Falls between RO and UF, removing some salts and organic compounds while allowing certain minerals to pass through.

Can I use AQT’s water treatment systems for seawater desalination?

Yes! We provide seawater desalination systems using advanced reverse osmosis (RO) technology, specifically designed to convert seawater into fresh, drinkable water. These systems are ideal for coastal communities, marine applications, and industrial desalination projects.

Water Filters

How do I choose between a media filter and a micron filter?

Media filters are ideal for high-volume solids removal and can be backwashed. Micron filters offer precise filtration for fine particles and are best for polishing applications.

Solutions

Can I use AQT’s water treatment systems for seawater desalination?

Yes! We provide seawater desalination systems using advanced reverse osmosis (RO) technology, specifically designed to convert seawater into fresh, drinkable water. These systems are ideal for coastal communities, marine applications, and industrial desalination projects.

How do I choose the right water treatment system for my needs?

The choice depends on factors such as water quality, application, flow rate, and purification requirements. Our team of experts can analyze your water source and recommend the most suitable solution for residential, commercial, or industrial applications.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWE Series

TWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for tap water (lower TDS). The large volumes can help meet your a variety of industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo