What operator training is essential for RO plants?

- Understanding Reverse Osmosis Systems and Operator Training

- 1. What Are Reverse Osmosis Systems?

- 2. How Do Reverse Osmosis Systems Work?

- 3. What Are the Benefits of Reverse Osmosis Systems?

- 4. What Are the Maintenance Requirements for Reverse Osmosis Systems?

- 5. What Are the Essential Operator Training Requirements for RO Plants?

- 6. How Do I Choose the Right Reverse Osmosis System for My Needs?

- 7. Are There Any Limitations to Reverse Osmosis Systems?

- 8. How Can I Ensure the Longevity of My Reverse Osmosis System?

- Conclusion: Why Choose AQUALITEK for Your Reverse Osmosis Needs?

Understanding Reverse Osmosis Systems and Operator Training

Reverse osmosis (RO) systems are pivotal in water purification, effectively removing contaminants to provide clean, safe drinking water. For water treatment professionals, comprehending the intricacies of RO systems and ensuring proper operator training are essential for optimal performance and longevity.

1. What Are Reverse Osmosis Systems?

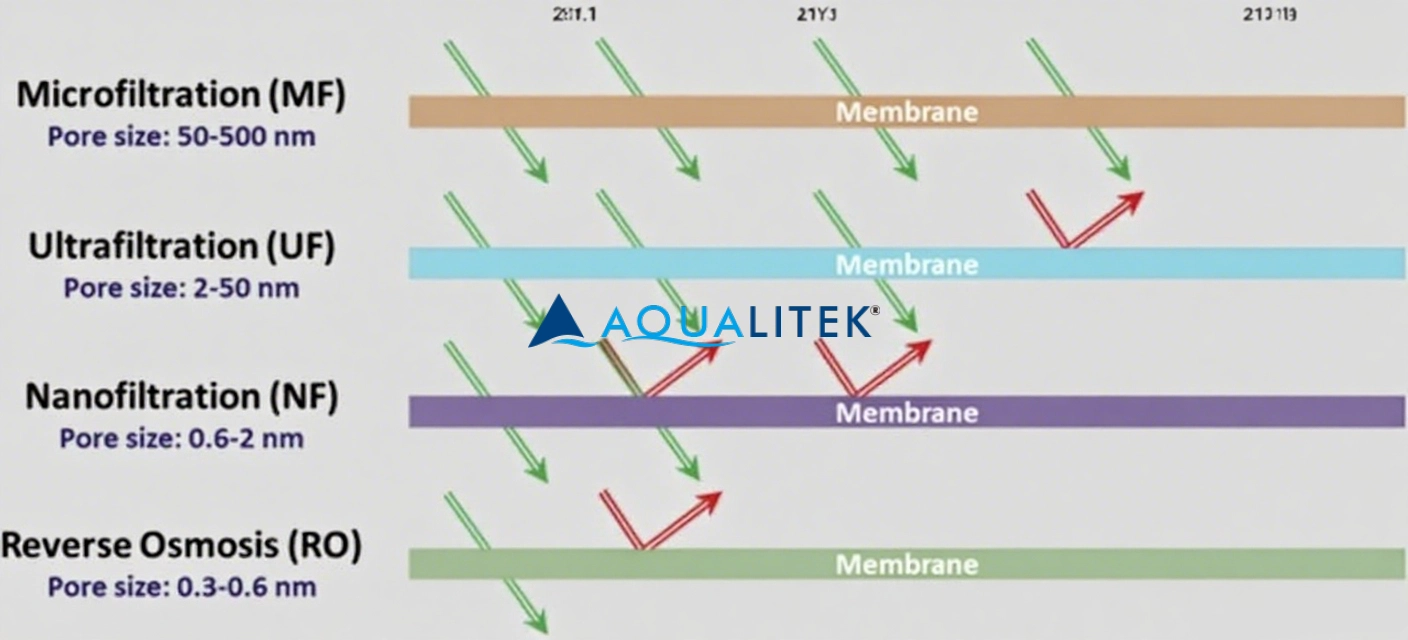

Reverse osmosis systems utilize a semi-permeable membrane to separate dissolved solids, contaminants, and impurities from water. The process involves applying pressure to force water through the membrane, allowing only water molecules to pass while blocking larger molecules and contaminants. This results in purified water suitable for various applications, including drinking, cooking, and industrial processes.

2. How Do Reverse Osmosis Systems Work?

The RO process typically includes several stages:

Pre-Filtration: Water passes through sediment and carbon filters to remove larger particles, chlorine, and other impurities.

Reverse Osmosis Membrane: The filtered water is then forced through the RO membrane, which removes dissolved solids and contaminants.

Post-Filtration: The purified water undergoes a final filtration stage to remove any remaining impurities, ensuring high-quality output.

3. What Are the Benefits of Reverse Osmosis Systems?

RO systems offer numerous advantages:

Effective Contaminant Removal: They can remove up to 99% of contaminants, including heavy metals, salts, and microorganisms.

Improved Water Taste and Odor: By eliminating impurities, RO systems enhance the taste and odor of water.

Cost-Effective: They provide a long-term solution for clean water, reducing the need for bottled water.

4. What Are the Maintenance Requirements for Reverse Osmosis Systems?

Regular maintenance is crucial for the efficient operation of RO systems:

Filter Replacement: Pre-filters and post-filters should be replaced every 6 to 12 months, depending on water quality and usage.

Membrane Replacement: The RO membrane typically lasts 2 to 3 years but should be replaced if performance declines.

System Sanitization: Periodic cleaning and sanitization prevent bacterial growth and maintain water quality.

5. What Are the Essential Operator Training Requirements for RO Plants?

Proper training ensures safe and efficient operation of RO plants:

System Operation: Operators should understand the RO process, including start-up, shutdown, and monitoring procedures.

Maintenance Procedures: Training on routine maintenance tasks, such as filter and membrane replacement, is essential.

Troubleshooting: Operators should be equipped to identify and resolve common issues, such as pressure drops or membrane fouling.

Safety Protocols: Knowledge of safety measures, including handling chemicals and emergency response, is vital.

6. How Do I Choose the Right Reverse Osmosis System for My Needs?

Selecting the appropriate RO system involves considering:

Water Quality: Assess the specific contaminants present in your water supply.

Water Usage: Determine the required flow rate and daily water volume.

System Features: Consider additional features like remineralization, UV sterilization, or permeate pumps.

Budget: Evaluate the initial investment and ongoing maintenance costs.

7. Are There Any Limitations to Reverse Osmosis Systems?

While RO systems are effective, they have some limitations:

Water Waste: Traditional RO systems can waste 3 to 4 gallons of water for every gallon purified. However, modern systems with permeate pumps can reduce this ratio significantly.

Mineral Removal: RO systems remove beneficial minerals from water. Some systems offer remineralization stages to add essential minerals back into the purified water.

Installation Requirements: Proper installation is crucial for optimal performance and may require professional assistance.

8. How Can I Ensure the Longevity of My Reverse Osmosis System?

To extend the lifespan of your RO system:

Regular Maintenance: Follow the manufacturer's maintenance schedule for filter and membrane replacement.

Monitor Performance: Keep an eye on water quality and system pressure to detect issues early.

Professional Servicing: Schedule periodic professional inspections to ensure all components are functioning correctly.

Conclusion: Why Choose AQUALITEK for Your Reverse Osmosis Needs?

AQUALITEK offers advanced reverse osmosis systems designed for efficiency and durability. Their products feature high-quality membranes, user-friendly interfaces, and comprehensive support, making them a reliable choice for both residential and commercial applications.

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

Anti-Scalant is a specialized water treatment chemical designed to prevent the formation of scale in reverse osmosis (RO) systems. Scaling is a common issue in RO systems, where minerals like calcium, magnesium, and silica precipitate and form hard deposits on the membrane surface. These deposits can clog the membranes, reduce water production efficiency, and increase operational costs.

RO chemical anti-scalants work by inhibiting the crystallization of scale-forming minerals, effectively keeping them in solution and preventing them from adhering to the membrane. This ensures the longevity and optimal performance of the RO system.

Anti-scalants are essential in applications with hard water or high mineral content, such as in industrial, municipal, and desalination plants.

These chemicals are highly effective in preventing scaling caused by common minerals such as calcium carbonate, calcium sulfate, barium sulfate, and silica, helping to extend the lifespan of the membranes, reduce cleaning cycles, and enhance system efficiency.

By incorporating an RO chemical anti-scalant into your water treatment process, you can improve the reliability and overall performance of your reverse osmosis system, ensuring consistent, high-quality water output while minimizing maintenance costs.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo