How to select pressure vessel configuration for RO trains?

- Understanding Reverse Osmosis Systems and Pressure Vessel Selection

- 1. What Are the Common Issues in Reverse Osmosis Systems?

- 2. How Do I Select the Appropriate Pressure Vessel Configuration for RO Trains?

- 3. What Factors Influence the Sizing of Commercial RO Pressure Vessels?

- 4. How Does the Operating Environment Affect Pressure Vessel Selection?

- 5. What Are the Energy Efficiency Considerations in RO System Design?

- 6. How Do I Ensure Compliance with Industry Standards in RO System Procurement?

- 7. What Are the Maintenance Requirements for RO Systems?

- 8. How Do I Evaluate the Total Cost of Ownership for an RO System?

- Conclusion: Why Choose AQUALITEK for Your RO System Needs?

Understanding Reverse Osmosis Systems and Pressure Vessel Selection

Reverse osmosis (RO) systems are pivotal in water purification, effectively removing contaminants to produce high-quality water. Selecting the appropriate pressure vessel configuration is crucial for optimizing system performance and longevity. This guide addresses common concerns and provides insights into making informed decisions when procuring RO systems.

1. What Are the Common Issues in Reverse Osmosis Systems?

RO systems may encounter several challenges:

Membrane Fouling: Accumulation of contaminants on membrane surfaces, leading to reduced efficiency.

Scaling: Mineral deposits forming on membranes, hindering water flow.

Chemical Degradation: Membrane damage due to exposure to harsh chemicals.

Pressure Fluctuations: Variations in system pressure affecting performance.

Energy Consumption: High operational costs associated with energy-intensive processes.

2. How Do I Select the Appropriate Pressure Vessel Configuration for RO Trains?

Choosing the right pressure vessel configuration involves:

Membrane Compatibility: Ensuring the vessel accommodates the specific membrane type and size.

Pressure Rating: Selecting vessels with pressure ratings matching the system's operating conditions.

Material Selection: Opting for materials like fiberglass-reinforced plastic (FRP) for corrosion resistance or stainless steel for durability.

Number of Membranes: Determining the required number of membranes per vessel based on water production needs.

Flow Rate Considerations: Ensuring the vessel supports the desired flow rate without excessive pressure drop.

Maintenance Accessibility: Choosing designs that facilitate easy maintenance and membrane replacement.

3. What Factors Influence the Sizing of Commercial RO Pressure Vessels?

Key factors include:

Feed Water Characteristics: Total dissolved solids (TDS) concentration and temperature affect vessel sizing.

Production Capacity: Daily water production targets guide the number and size of vessels.

Recovery Rate: Desired recovery rates impact the configuration and number of vessels.

Operating Pressure: Higher pressures require vessels with appropriate pressure ratings.

Temperature Limitations: Material selection must account for expected operating temperatures.

Chemical Compatibility: Vessels must withstand the chemical composition of feed water.

4. How Does the Operating Environment Affect Pressure Vessel Selection?

The operating environment plays a significant role in vessel selection:

Corrosive Conditions: Environments with high salinity or chemical exposure necessitate corrosion-resistant materials.

Temperature Extremes: Vessels must be designed to handle ambient temperature variations.

Space Constraints: Available installation space influences vessel size and configuration.

5. What Are the Energy Efficiency Considerations in RO System Design?

Optimizing energy efficiency involves:

High-Pressure Pump Selection: Utilizing pumps with high efficiency to reduce energy consumption.

Energy Recovery Devices (ERDs): Implementing ERDs to recover and reuse energy within the system.

System Configuration: Designing systems with optimal pressure vessel arrangements to minimize energy use.

Operational Strategies: Adjusting recovery rates and operating pressures to balance performance and energy consumption.

6. How Do I Ensure Compliance with Industry Standards in RO System Procurement?

Ensuring compliance involves:

Adhering to Regulatory Standards: Familiarizing with and following relevant industry standards and codes.

Selecting Certified Components: Choosing equipment and materials that meet recognized certifications.

Engaging Qualified Suppliers: Partnering with manufacturers experienced in RO system design and compliance.

Conducting Thorough Testing: Verifying system performance through rigorous testing protocols.

7. What Are the Maintenance Requirements for RO Systems?

Regular maintenance is essential for optimal performance:

Routine Inspections: Regularly checking system components for signs of wear or damage.

Cleaning Protocols: Implementing cleaning procedures to address fouling and scaling.

Membrane Replacement: Scheduling periodic membrane replacements based on performance metrics.

System Calibration: Ensuring all instruments and controls are accurately calibrated.

8. How Do I Evaluate the Total Cost of Ownership for an RO System?

Evaluating total cost involves:

Initial Capital Expenditure: Assessing the upfront costs of equipment and installation.

Operational Costs: Considering energy consumption, water usage, and labor expenses.

Maintenance Costs: Estimating expenses for routine maintenance and unexpected repairs.

Lifecycle Analysis: Projecting the system's operational lifespan and associated costs over time.

Conclusion: Why Choose AQUALITEK for Your RO System Needs?

AQUALITEK stands out in the water treatment industry by offering:

Expertise: A team of professionals with extensive experience in RO system design and implementation.

Quality Assurance: Commitment to providing high-quality, durable, and efficient RO systems.

Customer Support: Dedicated support throughout the system's lifecycle, from installation to maintenance.

Innovation: Continuous research and development to incorporate the latest technologies and best practices.

By partnering with AQUALITEK, you ensure a reliable and efficient water treatment solution tailored to your specific requirements.

References:

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

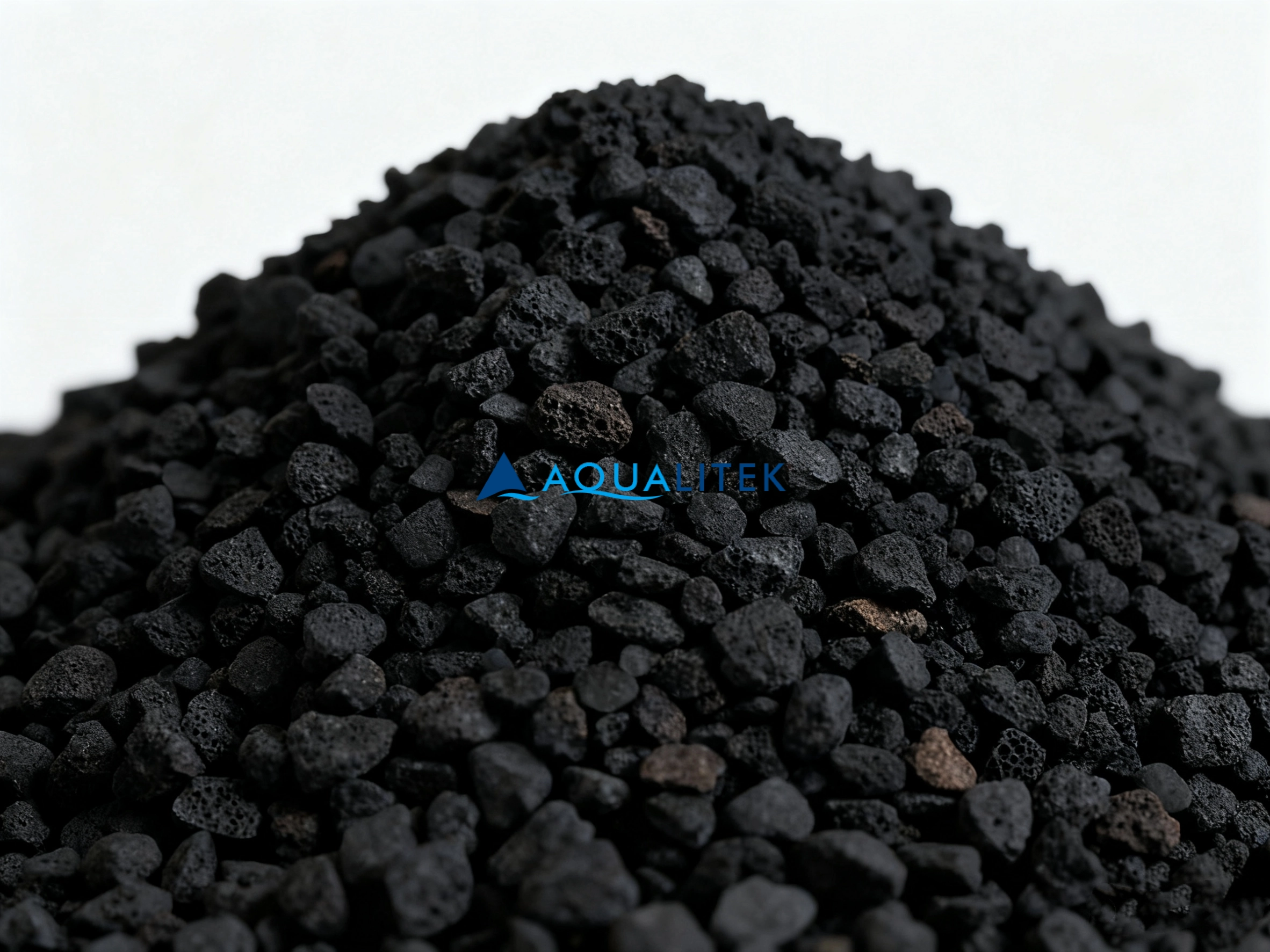

Anti-Scalant is a specialized water treatment chemical designed to prevent the formation of scale in reverse osmosis (RO) systems. Scaling is a common issue in RO systems, where minerals like calcium, magnesium, and silica precipitate and form hard deposits on the membrane surface. These deposits can clog the membranes, reduce water production efficiency, and increase operational costs.

RO chemical anti-scalants work by inhibiting the crystallization of scale-forming minerals, effectively keeping them in solution and preventing them from adhering to the membrane. This ensures the longevity and optimal performance of the RO system.

Anti-scalants are essential in applications with hard water or high mineral content, such as in industrial, municipal, and desalination plants.

These chemicals are highly effective in preventing scaling caused by common minerals such as calcium carbonate, calcium sulfate, barium sulfate, and silica, helping to extend the lifespan of the membranes, reduce cleaning cycles, and enhance system efficiency.

By incorporating an RO chemical anti-scalant into your water treatment process, you can improve the reliability and overall performance of your reverse osmosis system, ensuring consistent, high-quality water output while minimizing maintenance costs.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo