How to troubleshoot low permeate flow in RO systems?

- Understanding Reverse Osmosis Systems: Troubleshooting and Maintenance

- 1. What Causes Low Permeate Flow in Reverse Osmosis Systems?

- 2. How Do I Troubleshoot Low Permeate Flow?

- 3. What Are the Common Causes of Leaks in Reverse Osmosis Systems?

- 4. How Can I Improve the Taste and Odor of RO Water?

- 5. What Are the Maintenance Best Practices for RO Systems?

- 6. How Do I Troubleshoot a Reverse Osmosis System?

- 7. What Are the Signs That My RO System Needs Professional Service?

- Conclusion: Why Choose AQUALITEK for Your Water Treatment Needs?

Understanding Reverse Osmosis Systems: Troubleshooting and Maintenance

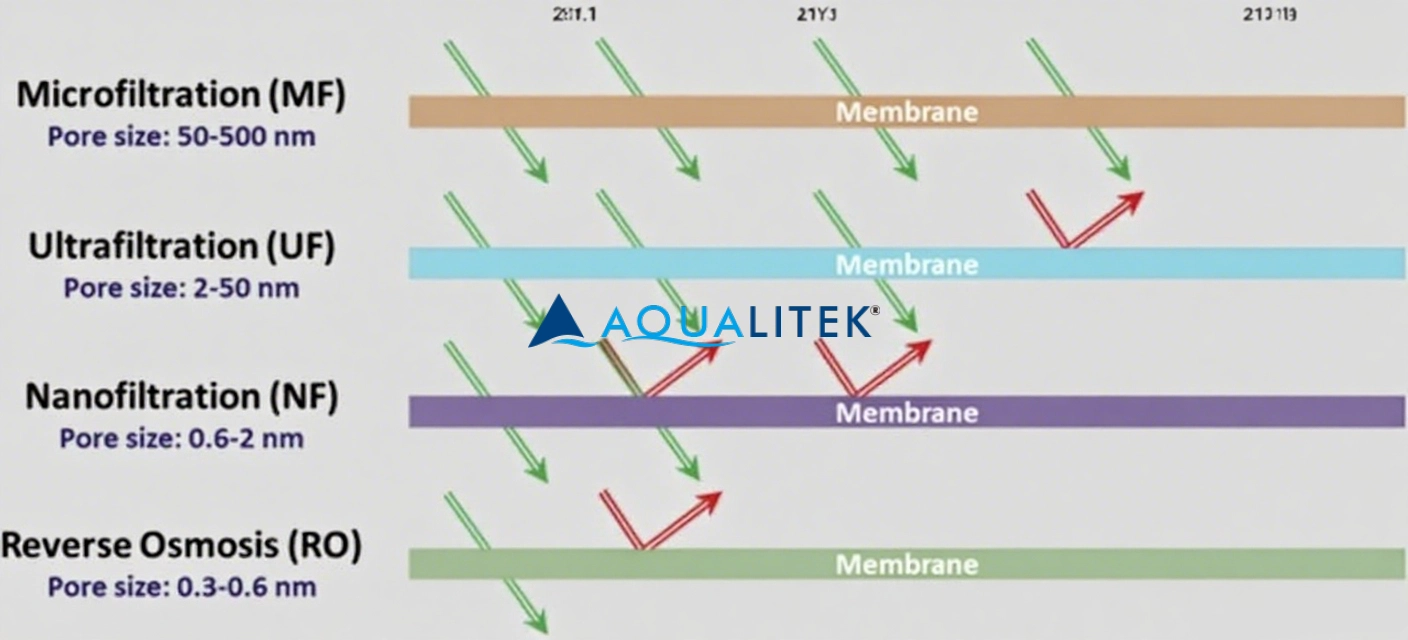

Reverse osmosis (RO) systems are essential for providing purified drinking water by removing contaminants through a semi-permeable membrane. However, like all systems, they can encounter issues that affect their performance. This guide addresses common problems, troubleshooting steps, and maintenance practices to ensure your RO system operates efficiently.

1. What Causes Low Permeate Flow in Reverse Osmosis Systems?

Low permeate flow can result from several factors:

Insufficient Feed Water Pressure: RO systems typically require a feed pressure between 40 to 60 psi. If the incoming water pressure is below this range, permeate flow can decrease significantly.

Clogged Filters: Over time, sediment and carbon filters can become clogged, restricting water flow into the membrane housing and reducing pressure at the membrane.

Faulty Storage Tank: A damaged bladder or incorrect fittings in the storage tank can lead to low water pressure and reduced flow.

Cold Feed Water Temperature: Water temperature affects RO performance. For instance, water at 47°F can reduce output by approximately 60% compared to water at 77°F, even if pressure remains constant.

2. How Do I Troubleshoot Low Permeate Flow?

To address low permeate flow:

Check Feed Water Pressure: Use a pressure gauge to ensure the feed water pressure is within the recommended range. If it's low, consider installing a booster pump.

Inspect and Replace Filters: Examine sediment and carbon filters for clogging. Replace them if they appear dirty or have been in use for their recommended lifespan.

Assess Storage Tank Pressure: Measure the air pressure in the storage tank. If it's low, repressurize it to the manufacturer's specified psi.

Evaluate Water Temperature: Measure the feed water temperature. If it's below the optimal range, consider installing a water heater or allowing the water to warm naturally.

3. What Are the Common Causes of Leaks in Reverse Osmosis Systems?

Leaks can occur due to:

Loose Fittings: Over time, connections can loosen, leading to drips or puddles. Regularly inspect and tighten all fittings.

Worn O-Rings: These seals can degrade, causing leaks. Replace them as part of routine maintenance.

Damaged Storage Tank Bladder: A ruptured bladder can lead to leaks. If the tank is leaking, it may need replacement.

4. How Can I Improve the Taste and Odor of RO Water?

To enhance water taste and odor:

Replace Filters Regularly: Old filters can harbor bacteria, leading to unpleasant tastes. Replace sediment and carbon filters every 6 to 12 months.

Sanitize the System: Periodically clean and sanitize the RO system, including the storage tank, to prevent biofilm buildup.

Check for Stagnant Water: If the system hasn't been used for a while, flush it thoroughly to remove any stagnant water that may cause odors.

5. What Are the Maintenance Best Practices for RO Systems?

To maintain optimal performance:

Regular Filter Replacement: Adhere to the manufacturer's schedule for replacing filters and membranes. This prevents clogging and ensures efficient operation.

Monitor Water Pressure: Ensure that both feed and storage tank pressures are within recommended ranges. Install pressure gauges for easy monitoring.

Sanitize Periodically: Clean and sanitize the system, including the storage tank, every 6 months to prevent bacterial growth.

Inspect for Leaks: Regularly check all connections and components for signs of leaks or wear. Address issues promptly to prevent water damage.

6. How Do I Troubleshoot a Reverse Osmosis System?

For effective troubleshooting:

Identify the Problem: Determine whether the issue is related to water flow, taste, pressure, or leaks.

Consult the Manual: Refer to the manufacturer's troubleshooting guide for specific issues.

Seek Professional Help: If basic troubleshooting doesn't resolve the problem, contact a certified technician for assistance.

7. What Are the Signs That My RO System Needs Professional Service?

Consider professional service if you notice:

Persistent Low Water Flow: Despite troubleshooting, the issue persists.

Continuous Leaks: Leaks that don't resolve with tightening or replacing parts.

Unusual Noises: Sounds like gurgling or hissing that don't subside.

Water Quality Issues: Persistent bad taste, odor, or cloudiness.

Regular maintenance and prompt attention to issues can extend the lifespan of your RO system and ensure the delivery of clean, safe drinking water.

Conclusion: Why Choose AQUALITEK for Your Water Treatment Needs?

AQUALITEK offers advanced reverse osmosis systems designed for efficiency and durability. With a focus on quality components and user-friendly features, AQUALITEK ensures optimal water purification for both residential and commercial applications. Trust AQUALITEK to provide reliable solutions for all your water treatment requirements.

Sources:

Request More Information or Expert Advice

Share a few details, and we’ll provide deeper insights, tailored suggestions, or product support.

Anti-Scalant is a specialized water treatment chemical designed to prevent the formation of scale in reverse osmosis (RO) systems. Scaling is a common issue in RO systems, where minerals like calcium, magnesium, and silica precipitate and form hard deposits on the membrane surface. These deposits can clog the membranes, reduce water production efficiency, and increase operational costs.

RO chemical anti-scalants work by inhibiting the crystallization of scale-forming minerals, effectively keeping them in solution and preventing them from adhering to the membrane. This ensures the longevity and optimal performance of the RO system.

Anti-scalants are essential in applications with hard water or high mineral content, such as in industrial, municipal, and desalination plants.

These chemicals are highly effective in preventing scaling caused by common minerals such as calcium carbonate, calcium sulfate, barium sulfate, and silica, helping to extend the lifespan of the membranes, reduce cleaning cycles, and enhance system efficiency.

By incorporating an RO chemical anti-scalant into your water treatment process, you can improve the reliability and overall performance of your reverse osmosis system, ensuring consistent, high-quality water output while minimizing maintenance costs.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

30TPH Industrial Reverse Osmosis (RO) System designed for industrial and municipal water treatment. High salt rejection, energy-efficient design, PLC control, and customizable configuration.

AQUALITEK's 500LPH Panel Mounted Reverse Osmosis Water Purification System delivers reliable 500 LPH RO water production. This compact industrial reverse osmosis unit is ideal for small scale industrial RO needs, ensuring efficient and high-quality purified water in a space-saving design.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo