Industrial Water Purification Systems: Key Considerations for Buyers

- Introduction: Why Industrial Water Purification Systems Matter

- Purpose and commercial value of industrial water purification systems

- Understand Your Feed Water and Quality Targets

- Analyze feed water to define design goals for industrial water purification systems

- Core Technologies and When to Use Them

- Select core technologies—RO, UF, MBR, EDI—based on application

- Technology comparison for industrial water purification systems

- Pretreatment: The Foundation of Reliable Systems

- Invest in pretreatment to protect core units and lower lifecycle costs

- System Capacity, Recovery, and Reject Management

- Balance capacity, recovery rates, and brine handling to meet operational needs

- Energy, Operating Costs, and Lifecycle Considerations

- Assess total cost of ownership, not just capital cost

- Materials, Configuration, and Footprint

- Match materials and system layout to process conditions and site constraints

- Automation, Monitoring and Compliance

- Modern controls and real-time monitoring reduce risk and support compliance

- Choosing the Right Supplier and Custom Solutions

- Evaluate supplier expertise, manufacturing capability, and after-sales service

- Implementation, Commissioning and After-Sales Support

- Proper commissioning and service contracts ensure reliable performance

- Conclusion: Make Decisions That Balance Performance and Cost

- Key takeaways for selecting industrial water purification systems

- Frequently Asked Questions

Introduction: Why Industrial Water Purification Systems Matter

Purpose and commercial value of industrial water purification systems

Industrial water purification systems are central to product quality, regulatory compliance, operational efficiency, and sustainability. Whether you need high-purity ultrapure water for electronics, softened feed for boilers, or treated effluent for reuse, selecting the right industrial water treatment solutions reduces downtime, lowers costs, and protects equipment. This guide helps procurement managers, engineers, and facility owners evaluate systems and choose a water treatment systems manufacturer or partner that can deliver customized, cost-effective solutions.

Understand Your Feed Water and Quality Targets

Analyze feed water to define design goals for industrial water purification systems

Start with a detailed feed water analysis—TDS, hardness, turbidity, organics (TOC), suspended solids, biological load, specific ions (chloride, sulfate, silica), and temperature. Defining target water quality (e.g., boiler feedwater, process water, CIP rinse, or potable reuse) shapes the choice of industrial water purification technologies and pretreatment needs. Commercial buyers should specify flow (m3/h or GPM), required recovery, and regulatory limits up front to obtain accurate proposals from water treatment systems manufacturers.

Core Technologies and When to Use Them

Select core technologies—RO, UF, MBR, EDI—based on application

Industrial water purification systems rely on one or more core technologies. Reverse osmosis (RO) is the backbone for desalination and dissolved solids removal; ultrafiltration (UF) and microfiltration (MF) address suspended solids and colloids; membrane bioreactors (MBR) enable wastewater reuse; electrodeionization (EDI) and ion exchange polish to produce ultrapure water. Choosing the right combination reduces total cost of ownership and helps suppliers provide scalable solutions.

Technology comparison for industrial water purification systems

| Technology | Primary Use | Advantages | Typical Energy / Recovery |

|---|---|---|---|

| Reverse Osmosis (RO) | Brackish/seawater desalination, dissolved solids removal | High TDS rejection (>95%), modular, widely used | Energy: 0.5–6 kWh/m3 (brackish to seawater); Recovery: 40–85% (typical ranges) |

| Ultrafiltration (UF) | Suspended solids, bacteria, colloids, as pretreatment | Robust against turbidity spikes, low chemical use | Low energy; Recovery >90% |

| Membrane Bioreactor (MBR) | Wastewater treatment and reuse | High-quality effluent, small footprint vs. conventional plants | Moderate energy; dependent on aeration and permeation |

| Electrodeionization (EDI) | Polishing for ultrapure water (pharmaceuticals, electronics) | No chemical regenerants, continuous operation | Low incremental energy when fed by RO permeate |

| Ion Exchange | Softening, specific ion removal | Precise control of hardness and ionic composition | Energy minimal; requires regenerants |

| Distillation / Thermal | High-purity water, zero-liquid-discharge (ZLD) | Very high purity, handles complex feedwaters | High energy; used where membranes are impractical |

Pretreatment: The Foundation of Reliable Systems

Invest in pretreatment to protect core units and lower lifecycle costs

Pretreatment is critical in industrial water purification systems. Sediment filtration, multimedia filters, cartridge filters, antiscalant dosing, chlorination/ dechlorination, and UF protect RO membranes and downstream equipment. Proper pretreatment reduces fouling and prolongs membrane life, decreasing replacement costs and downtime. When sourcing industrial water treatment solutions, verify your supplier’s pretreatment design experience for similar feedwater conditions.

System Capacity, Recovery, and Reject Management

Balance capacity, recovery rates, and brine handling to meet operational needs

Specify required flow rate, peak demand, and recovery targets. Higher recovery reduces freshwater intake but increases scaling risk; the right balance depends on feedwater composition and pretreatment. Reject (concentrate) management is a key commercial consideration—options include brine disposal, evaporation, zero-liquid-discharge (ZLD) systems, or further treatment for reuse. A competent industrial water treatment systems manufacturer will model recovery-versus-cost and present practical reject management options tailored to your site.

Energy, Operating Costs, and Lifecycle Considerations

Assess total cost of ownership, not just capital cost

Operating expenses—energy, chemicals, consumables (membranes, resins), labor, and waste disposal—often exceed initial capital expenditure over the system lifetime. Energy-efficient RO with energy recovery devices and optimized operating pressures can significantly cut operating costs. Request lifecycle cost analyses from vendors and compare energy consumption, membrane replacement intervals, and chemical usage when evaluating industrial water purification systems.

Materials, Configuration, and Footprint

Match materials and system layout to process conditions and site constraints

Materials of construction must resist corrosion from feedwater chemistry and cleaning agents—common choices include stainless steel (316L), FRP, and PE/PP for specific components. Consider modular skid-mounted systems for faster installation and smaller footprints, or containerized units for mobility. When buying industrial water treatment solutions, ensure the supplier offers flexible configurations that fit your site layout and can scale with future demand.

Automation, Monitoring and Compliance

Modern controls and real-time monitoring reduce risk and support compliance

Automation improves water quality consistency and reduces manual intervention. Integrate PLC/SCADA for remote monitoring of key parameters—flow, pressures, conductivity/TDS, pH, ORP, and alarms. Compliance reporting (local discharge limits, potable standards, or industry-specific regulations) should be built into the control system. Selecting a water treatment systems manufacturer who provides digital monitoring and data logging helps demonstrate regulatory compliance and improves operational transparency.

Choosing the Right Supplier and Custom Solutions

Evaluate supplier expertise, manufacturing capability, and after-sales service

Partner with a manufacturer experienced in industrial water purification systems and with proven engineering, testing, and fabrication capabilities. Aqualitek Water Treatment Technologies Co., Ltd. (AQT), headquartered in Guangzhou, China, specializes in customized industrial water treatment solutions and high-quality component parts. Look for suppliers that offer site surveys, pilot testing, ISO-driven quality control, and local service networks to ensure smooth commissioning and long-term performance.

Implementation, Commissioning and After-Sales Support

Proper commissioning and service contracts ensure reliable performance

Successful projects include factory acceptance testing (FAT), site acceptance testing (SAT), operator training, and preventive maintenance programs. After-sales support—spare parts availability, remote diagnostics, and scheduled maintenance contracts—reduces downtime and protects your investment. When procuring industrial water purification systems, require clear KPIs and performance guarantees tied to acceptance tests.

Conclusion: Make Decisions That Balance Performance and Cost

Key takeaways for selecting industrial water purification systems

Choosing the right industrial water purification systems requires a data-driven approach: understand feedwater and target quality, select appropriate core technologies, invest in pretreatment, plan for reject management, and evaluate lifecycle costs. Prioritize suppliers that provide customized, tested solutions and strong after-sales support. Companies like Aqualitek (AQT) combine engineering expertise and manufacturing excellence to deliver reliable, scalable, and cost-effective industrial water treatment solutions for diverse applications.

Next steps: Commission a feedwater analysis and request a detailed proposal including lifecycle cost estimates and a pilot or demonstration plan to validate performance before full-scale purchase.

Frequently Asked Questions

What is the first step in selecting an industrial water purification system?

The first step is a comprehensive feed water analysis and a clear definition of target water quality, flow rate, and recovery targets. This data lets suppliers size systems and recommend pretreatment and core technologies.

How do I choose between RO, UF, and MBR for my facility?

Choose UF as pretreatment to remove turbidity and protect RO; use RO for dissolved solids removal and desalination; choose MBR for treating and reusing wastewater. Often systems are combined—for example, UF + RO + EDI for ultrapure water.

What are typical operating cost drivers for industrial water treatment solutions?

Energy consumption, membrane/resin replacements, chemicals (antiscalants, cleaning agents), labor, and waste disposal are the main operating cost drivers. Energy recovery and optimized designs can reduce OPEX significantly.

How should I manage RO concentrate (reject) from high-recovery systems?

Options include regulated discharge (if permitted), brine evaporation, ZLD solutions, or further treatment to recover valuable components. The best method depends on local regulations, disposal costs, and water scarcity.

Why is pretreatment crucial for long membrane life?

Pretreatment prevents fouling (biofouling, scaling, particulate fouling), which is the primary cause of membrane performance decline. Proper pretreatment lowers cleaning frequency and extends membrane service life, reducing lifecycle costs.

How can I assess supplier credibility for industrial water purification systems?

Evaluate project references, technical documentation, factory audits, certifications (e.g., ISO), pilot studies, warranty terms, and local service availability. Request case studies for similar feedwater and applications.

How the Best Reverse Osmosis Water Filter System Improves Taste

Performance Testing and QA for Stainless Micron Filter Housings

Compliance and Quality Standards for Ultrafiltration Water Systems

Operational Costs and ROI of Commercial Reverse Osmosis Systems

Ion Exchange Water Treatment Systems

Can ion exchange work with seawater or high-TDS water?

Ion exchange is more suitable for low to moderate TDS water. High-TDS applications often use RO as a primary treatment.

What is the difference between softening and deionization?

Softening removes only hardness ions (Ca²⁺, Mg²⁺), while deionization removes both cations and anions to produce high-purity water.

How often is regeneration needed?

It depends on water quality and usage. Most systems regenerate every few days to a week under normal loads.

FAQ-aqualitek

Are AQT’s water treatment products certified?

Yes! Our products comply with international quality and safety standards, including ISO, CE, and NSF certifications. We prioritize high-quality materials, advanced technology, and strict quality control to ensure superior performance and reliability.

Membrane Water Treatment Systems

Do you offer plug-and-play solutions?

Absolutely. We offer containerized membrane systems that are factory-tested, compact, and quick to deploy.

500 LPH Reverse Osmosis (RO) Water Purification Machine TWV - 412

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

Tap Water Reverse Osmosis (TWRO) Systems TWV Series

TWV series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 2.5”/4” membrane housings(single element type)for tap water(lower TDS).They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Tap Water Reverse Osmosis (TWRO) Systems TWF Series

TWF series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 4” membrane housings(multiple elements type) for tap water(lower TDS) .The medium large volumes can help meet your a variety of commercial and industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

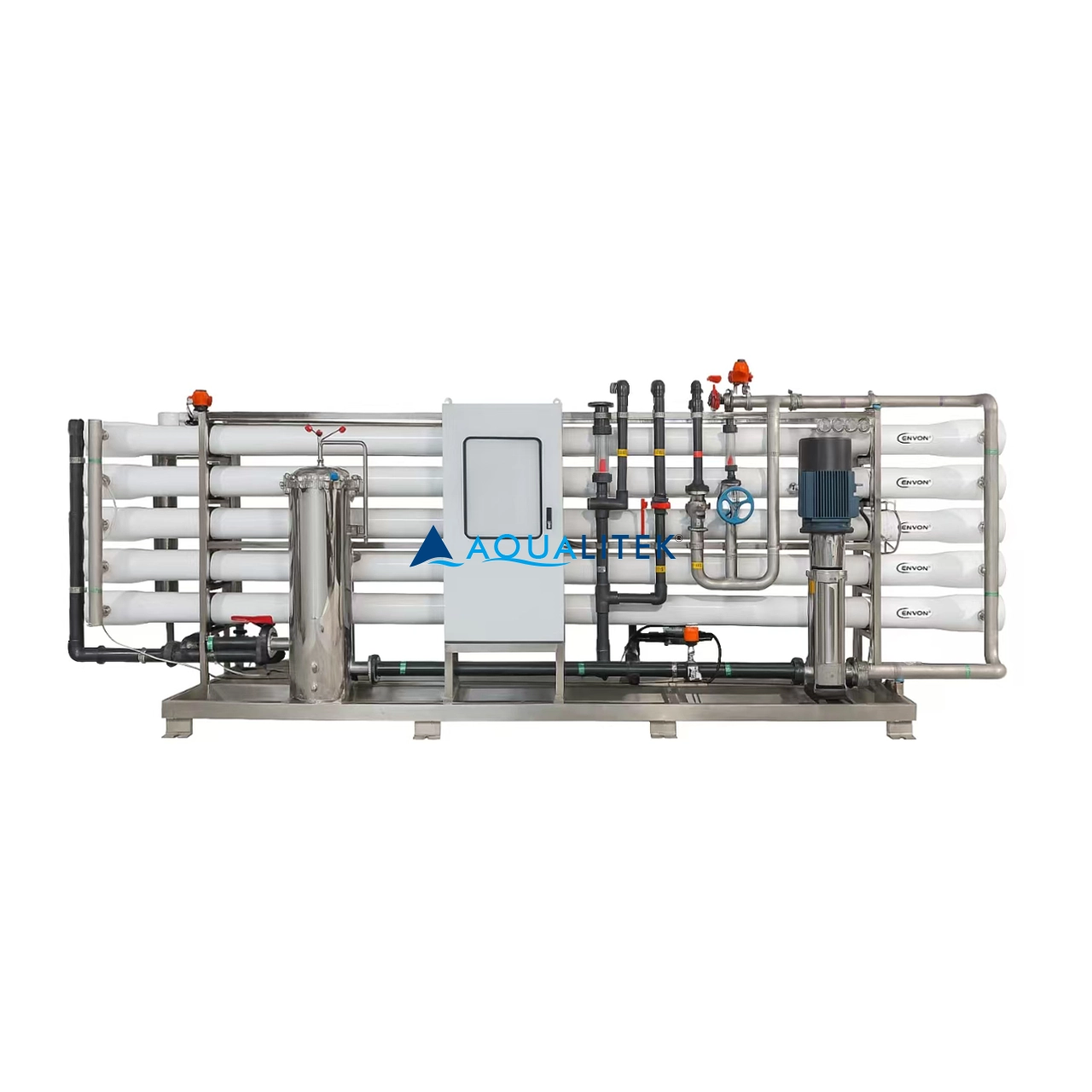

Tap Water Reverse Osmosis (TWRO) Systems TWE Series

TWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for tap water (lower TDS). The large volumes can help meet your a variety of industrial applications. They are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

Request More Information

Contact us today for product catalogs, customization options, and a free quotation designed for your business needs.

Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

© 2026 AQUALITEK. All rights reserved.

AQUALITEK- Aimee Hoo

AQUALITEK - Aimee Hoo