Containerized Seawater Desalination in Cape Verde

Cape Verde, an island nation off the coast of West Africa, faces seasonal freshwater scarcity due to limited natural water resources and increasing residential demand. A local utility company partnered with us to deploy a containerized seawater reverse osmosis (SWRO) system to provide reliable potable water for domestic use.

The objective was to design a system that is modular, easy to transport, quick to install, and capable of operating efficiently in coastal environments with high salinity and variable power conditions.

Our Solution: Containerized SWRO System

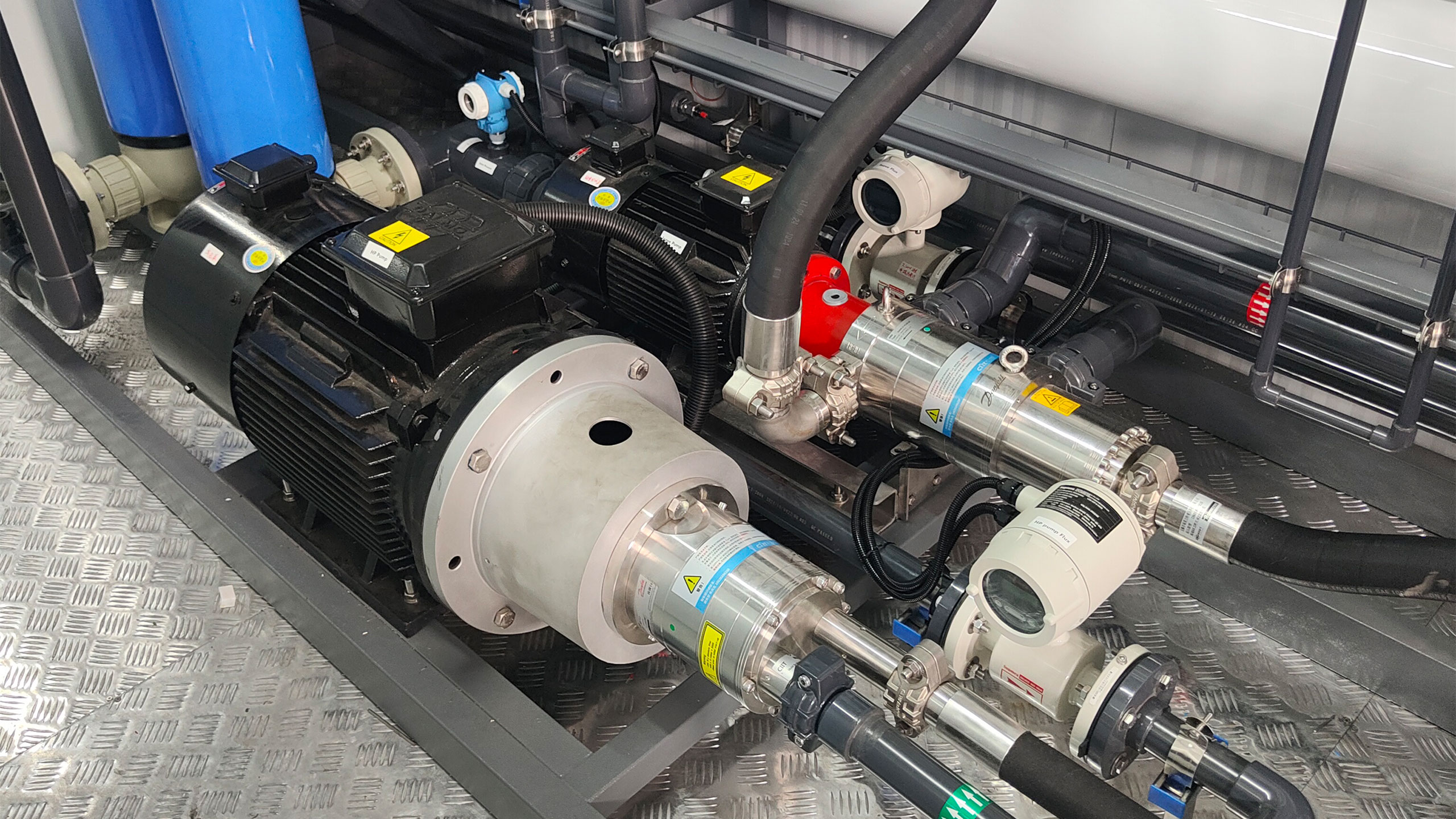

We supplied a fully integrated, containerized seawater desalination unit, built and tested at our facility before shipment. Key features of the system include:

- ISO 40-foot container, corrosion-resistant stainless steel frame, insulated and climate-adapted for marine use

- Production Capacity: 10 m³/h (10,000 liters/hour) of potable water

- Seawater RO Membranes: High-rejection membranes designed for >35,000 ppm TDS

- Pre-treatment System: Includes media filter (sand or MMF), cartridge filter, and antiscalant dosing

- Automation: PLC control with HMI panel, optional remote monitoring

- Power Supply: Configurable for 380V/50Hz or other regional standards

Technical Data Summary

| Parameter | Specification |

| Production Capacity | 10 m³/h (44 GPM) |

| Container Type | 40'' ISO, insulated, marine-grade |

| Feedwater Source | Seawater (TDS > 35,000 ppm) |

| Recovery Rate | Approx. 40-45% |

| Pretreatment | Multimedia filter + cartridge filter + dosing system |

| Pump | Danfoss pump with VFD |

| ERD | With Energy Recovery Device |

| Membrane Type | Dupont SW30HRLE-400 |

| Control System | PLC with HMI touch screen |

| Power Supply | 380V / 50Hz (customizable) |

| Output Water Use | Potable/domestic water supply |

Commissioning & Operation

The unit was delivered, installed, and commissioned in local.

Onsite testing confirmed the following:

- Product water TDS < 500 ppm

- Stable permeate flow of 10 m³/h over 24-hour cycles

- Smooth system operation, fully automatic with minimal operator intervention

- Withstood local temperature and salt-laden air conditions

Client Testimonial

“The system was plug-and-play. Within a week, we were producing high-quality fresh water. The container design makes it easy to maintain and relocate if needed. It’s a sustainable solution for our community.”

— Project Manager, Cape Verde

— Project Manager, Cape Verde

Project Highlights

- Modular container design: fast deployment, minimal civil work

- Reliable freshwater supply: even during dry seasons

- Built for harsh marine environments

- Remote monitoring for easy maintenance

- With energy recovery device

Interested in our cases? Contact us!

Share your real-world application to help us demonstrate product performance and industry-specific solutions.

Our 500 LPH Reverse Osmosis (RO) System is engineered to provide high-quality purified water for commercial applications. Designed with advanced RO technology, durable components, and a user-friendly interface, this system ensures consistent performance, low maintenance, and long-term reliability.

With its compact design and robust skid-mounted frame, it’s an excellent choice for businesses that demand efficiency and quality in water purification.

BWE series Reverse Osmosis (RO) systems are pre-engineered and pre-assembled units with 8” membrane housings for brackish water(higher TDS).The large volumes can help meet your a variety of industrial applications.T hey are designed for overall superior performance, high recovery rates and offer great savings with low maintenance and operation costs.

-

An IBC (Intermediate Bulk Container) tank is a robust, reusable industrial-grade vessel designed for the storage and transport of liquids, powders, and granules. Its space-efficient cubic shape and integrated pallet base make it ideal for easy handling and stacking, offering a cost-effective solution for bulk quantities.

UV Water Sterilizer Systems are advanced water purification devices that utilize ultraviolet (UV) light to eliminate harmful microorganisms such as bacteria, viruses, and protozoa from water. These systems are highly effective, environmentally friendly, and do not require the use of chemicals, making them a popular choice for both residential and commercial applications. UV sterilizers are often used in conjunction with other filtration methods, such as reverse osmosis or carbon filters, to ensure comprehensive water treatment. They are easy to install, require minimal maintenance, and provide a reliable method for ensuring safe and clean drinking water.

Copyright © 2025 AQUALITEK. All rights reserved.

AQT

AQT